A200SP Absorber 24 User Manual

Pre-use Checks

6.4 Inspiratory and Expiratory Non-return

Valve Test

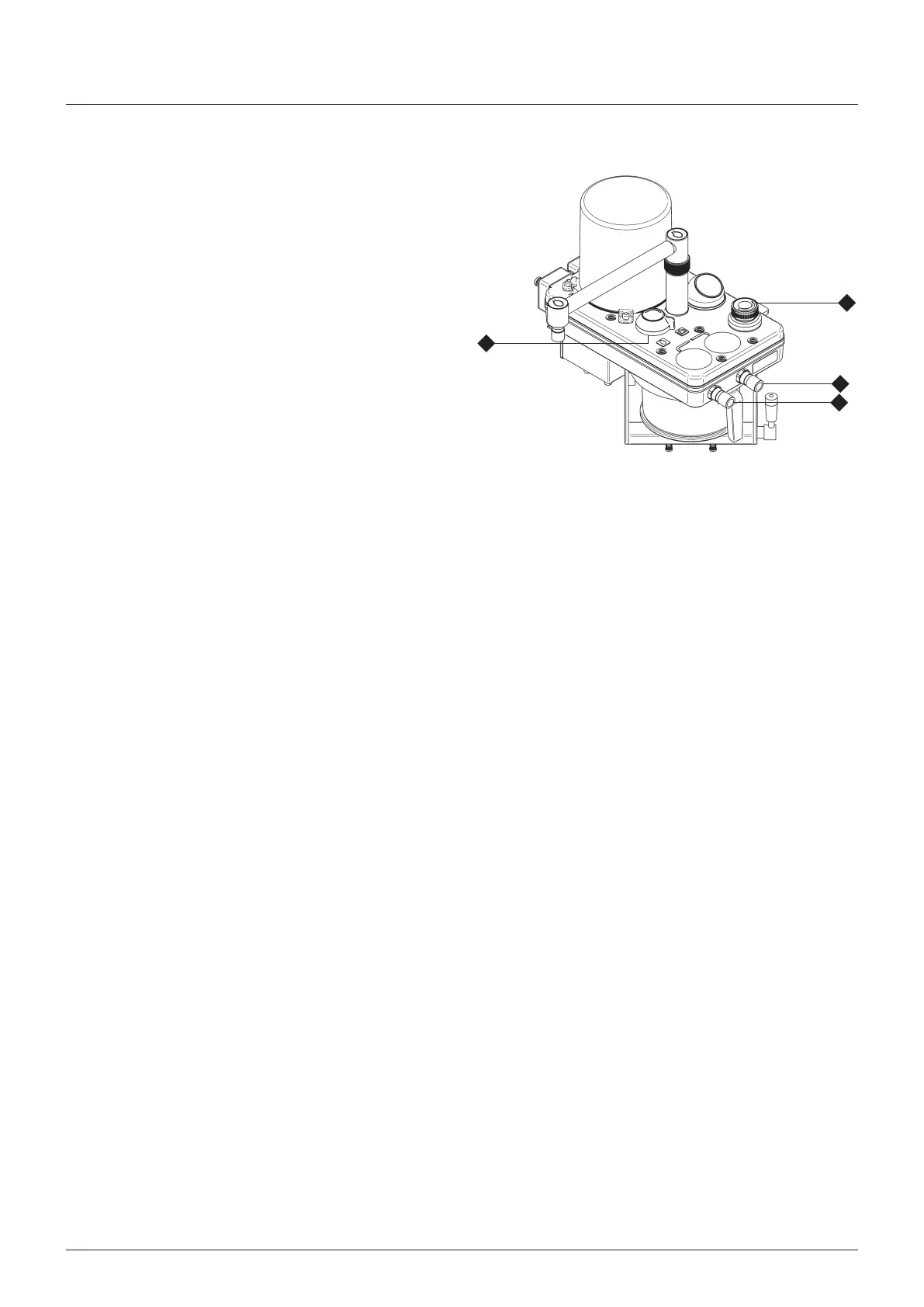

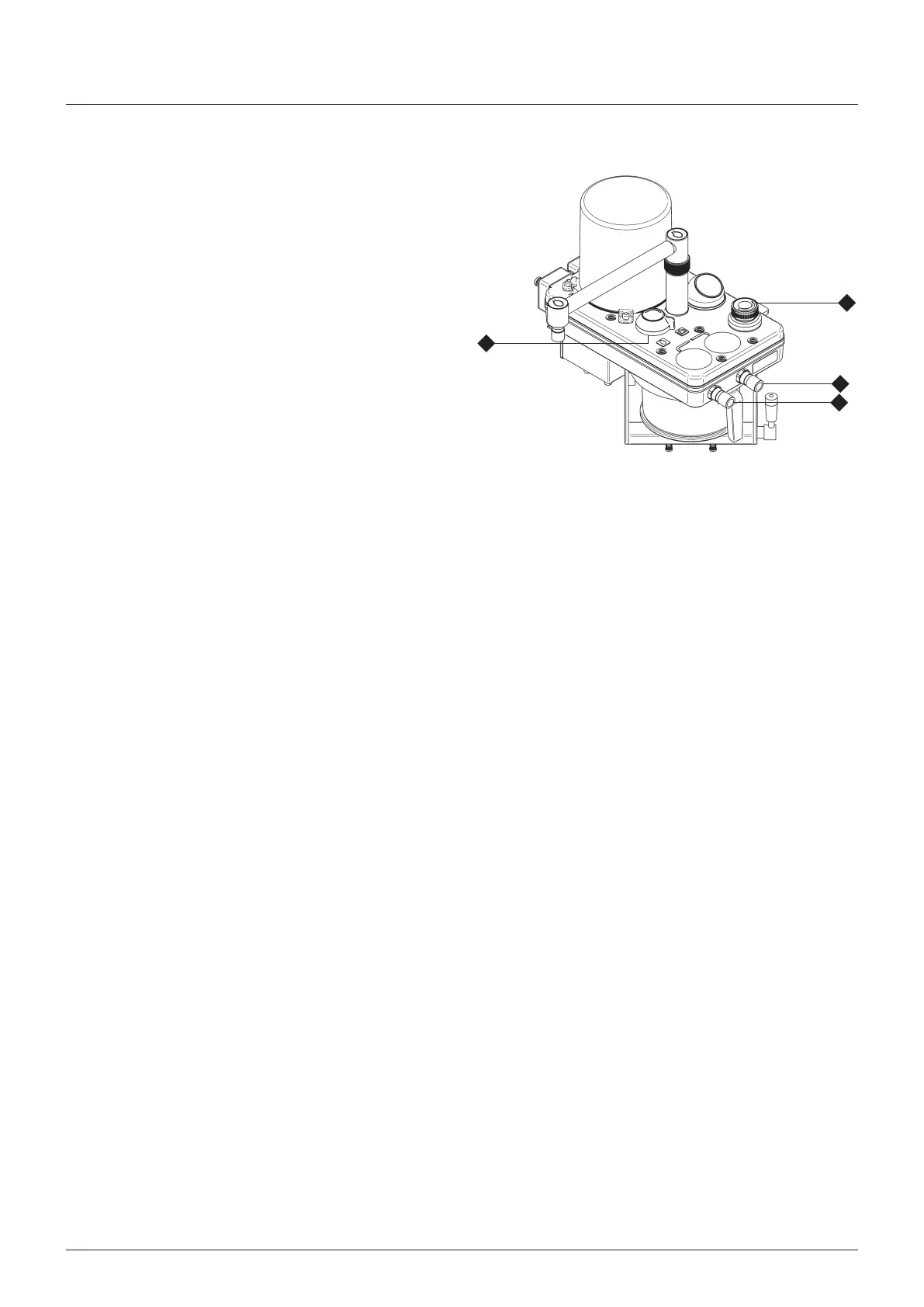

1 Detach the hose connectng the nspratory (1) and

expratory (2) connectors

2 heck that the adustable pressure lmtng (APL) valve (3)

s closed

3 Block the nspratory valve outlet (1) wth a sutable bung,

and nflate the reservor bag (not shown) wth a 2 L/mn

oxygen flow

4 Turn off the gas flow and check that the bag does not

empty by reverse flow through the expratory valve (2)

5 Remove the bung and attach a spare reservor bag to the

nspratory valve connector (1)

6 Turn on a 2 L/mn oxygen flow and fully nflate ths bag

(and the absorber reservor bag)

7 Turn off the gas flow heck that gas cannot be forced

through the nspratory valve by gentle squeezng of the

spare bag on the valve outlet

8 Remove the bag from the nspratory connector (1)

6.5 Bag/Ventilator switch test

1 Reft the breathng hose between the nspratory (1) and

expratory (2) connectors Set the bag/ventlator swtch (4)

to ‘Vent’

2 Set a flow of 10 L/mn and check that the bellows starts to

nflate

Ensure that the bag s not nflatng

3 Move the swtch (4) to Bag poston and watch the bag

nflate The bellows stops rsng

When the pressure reads 3 kPa (30 cmHO) turn off the

flow of gas

4 Select ventlator, the pressure on gauge should drop, but

the bag should reman nflated

5 Squeeze the bag, there should be no loss of pressure, and

the bellows must not rse

3

1

4

2

Loading...

Loading...