PAL-AT Operating Manual

47

5.6 Troubleshooting Guide

The following guide lists the most common encountered problems. Also, refer to the PAL-AT Installation

Manual for detailed installation information. If you are unable to resolve a problem, contact PermAlert

Field Technical Assistance at techsupport@permalert.com or 847-966-2190. It is helpful to have the serial

number of the system board and the firmware version as shown in message LCD1.2-01 of this manual. It

also can save time if you are at the panel during the phone call.

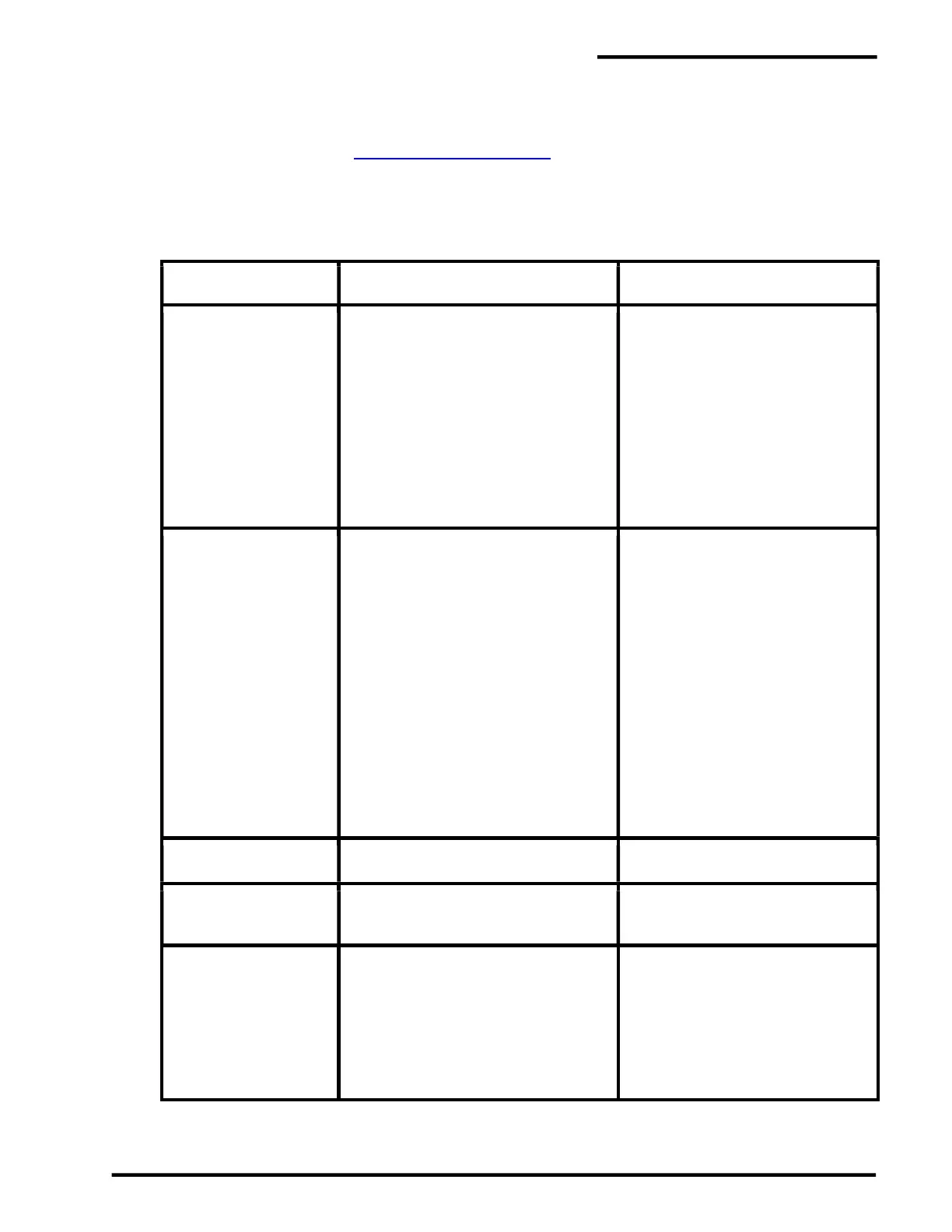

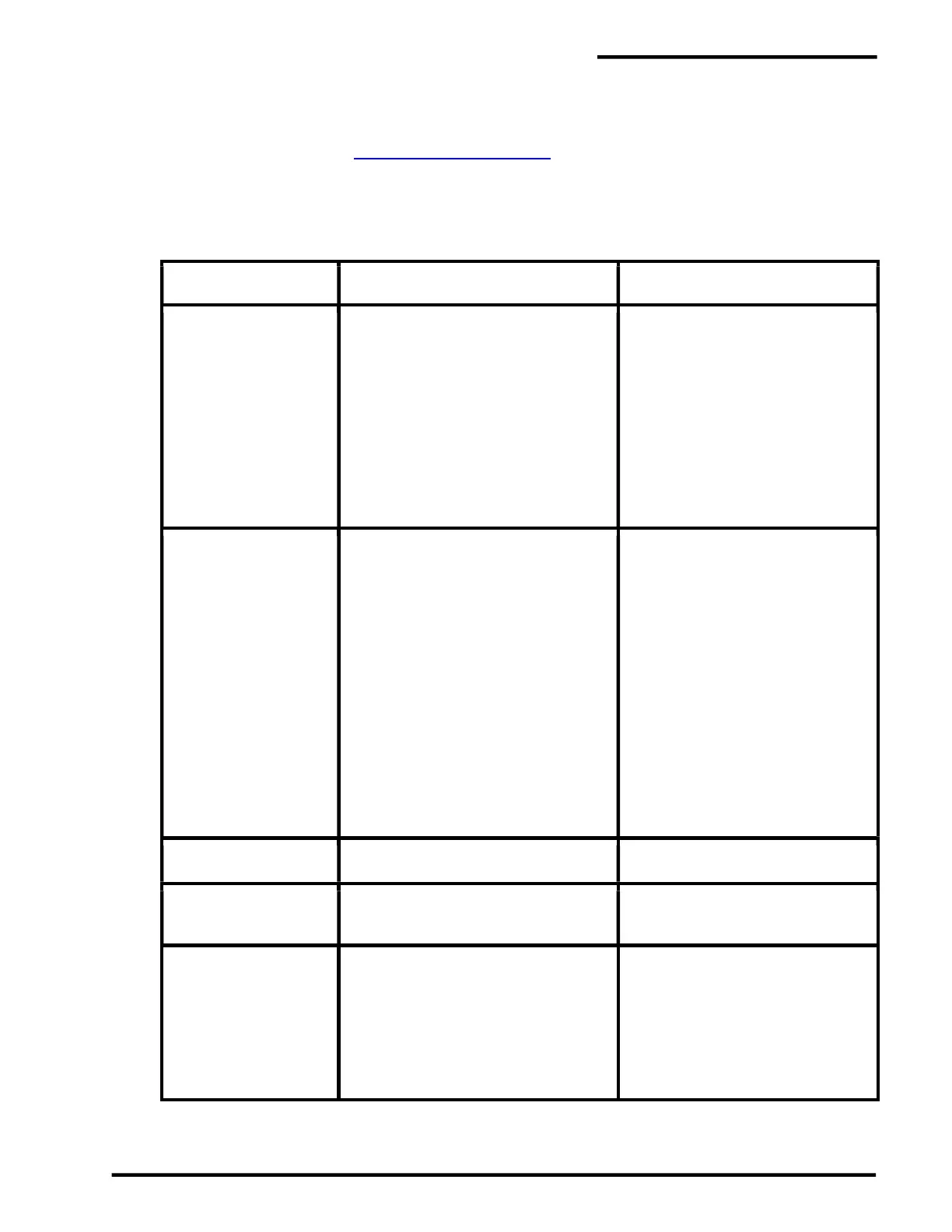

SYMPTOM POSSIBLE PROBLEM ACTION

LCD

No LCD backlight and

green LED on label off

No LCD backlight and

green LED on label on

No text in LCD

No power to PAL-AT.

Ribbon cable disconnected to LCD

Contrast is adjusted incorrectly.

LCD is defective

(Refer to figures 1-1, 1-2 or 4-1)

Check PAL-AT internal power switch

settings for AC/DC operation.

Measure input voltage at input

terminals.

Check 24 V DC fuse if DC source

used.

Make sure the cable is not twisted

between the LCD and system board

connector.

Adjust the contrast on system board.

See section 1.2.3.

Replace the LCD.

NO END FOUND

Or

FAULT IN 1

st

50 FEET

Jumper cable is disconnected/loose at

the cable plug in the PAL-AT panel.

Impedance Selection Jumper is incorrect

If a Zener Barrier Assembly is installed,

internal fuse failed.

If a Zener Barrier Panel is installed,

external surge suppressor fuse failed or

fuse holder is not closed.

The gain on the cable card is set too low

and there is a large section of cable wet.

Connector in the first 50 ft of the system

is faulty.

Tighten the terminal screws on the

cable plug. Make sure the plug is

pushed tight into the receptacle on

the system board.

Make sure the center conductor of

the cable is connected to the center

pin of the 3-pin connector.

See figure 1-1 or 1-2

Perform test in 5.4.1

Perform tests in 5.4.2

The gain is typically set to high for

hydrocarbon liquids and medium for

water-based liquids (see section

2.1.6.5).

Perform insulation and continuity

tests (see section 5.5).

BASELINE = 0 or not 25 to

35

Hardware failure.

Contact PermAlert.

DATE and TIME

PROBLEMS

Battery jumper not installed

Battery lost charge during power failure

Install jumper on 2 pins on processor

card (see section 4.4).

Replace battery (see section 4.4).

NO CABLES SET FOR

CONTINUOUS

MONITORING

No cables have been setup

Cables have been turned off-line

Intermittent connector

Use Setup function (3) to setup

cables

Use Verify function (4) to put cables

on-line.

Check History for sequence of

leaks/breaks/drying in a localized

area. Perform “Cable Connector

Tests” shown above on connectors

nearby to locate intermittent fault.

Loading...

Loading...