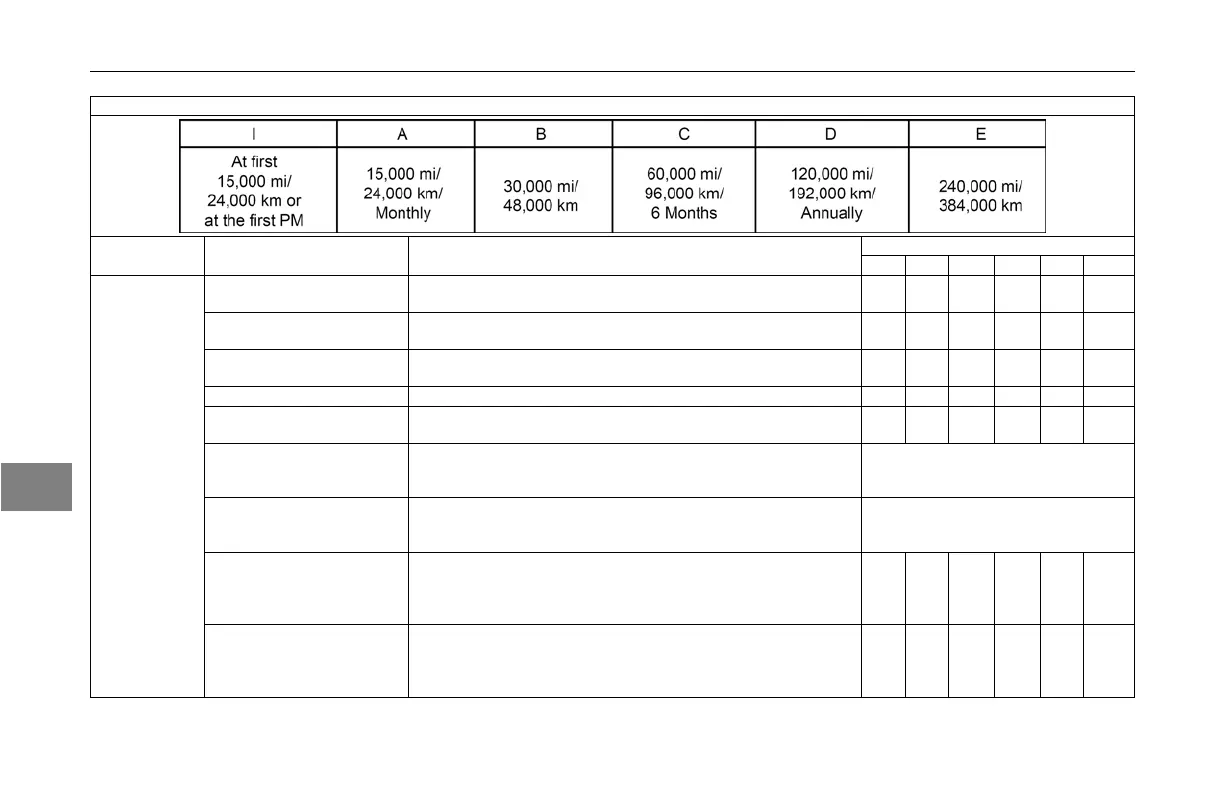

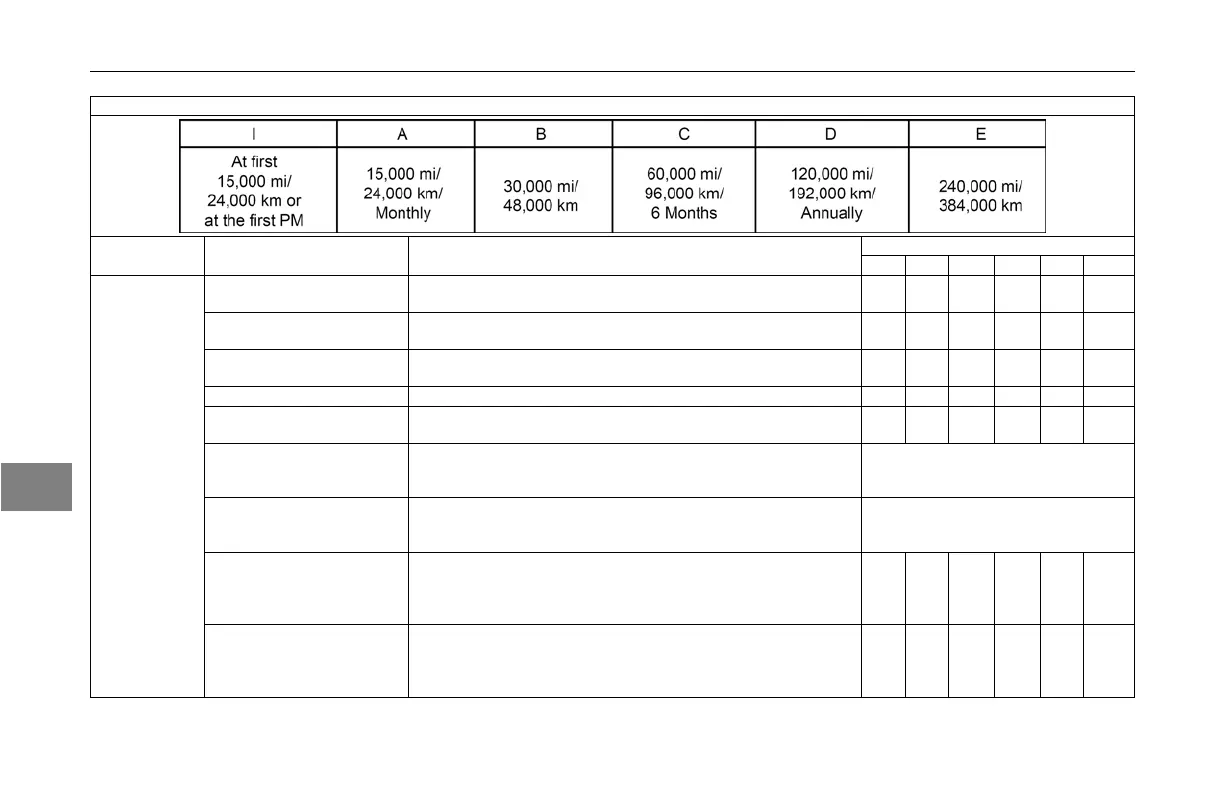

PREVENTIVE MAINTENANCE SCHEDULE

5

PREVENTIVE MAINTENANCE (PM) INTERVALS

SYSTEM COMPONENT MAINTENANCE TASK

Recommended PM

Interval

I A B

C

D E

Hub, Drum,

and Hubcap

Hubs (non-LMS) Check the bearing endplay and adjust as required (shown on

page 5-46).

X

Hubs (non-LMS)

with

outrunner seals

Clean the components and check for excessive wear or

damage. Change the oil and seal (shown on page 5-46).

X

Hubs (non-LMS)

with

standard seals

Clean the components and check for excessive wear or

damage. Change the oil and seal (shown on page 5-46).

X

Hub seals

(all) Check for leaks; replace as required.

X

LMS Hubs

(Dana) Inspect for leaks. Check the bearing endplay and adjust as

required (shown on page 5-46).

X

LMS Hubs

(Dana) with

Synthetic Lubricant

Service the bearings, seals and oil. This interval may be

different depending on the results of the regular inspection.

(shown on page 5-46).

500,000 miles/

800,000 km

LMS Hubs

(Dana) with

Mineral Lubricant

Service the bearings, seals and oil. This interval may be

different depending on the results of the regular inspection.

(shown on page 5-46).

350,000 miles/

560,000 km

Brake drums

Inspect for visible cracks, heat checking, galling or scoring of

the braking surface, and for severe corrosion on the outside

surface. Check for out-of-round or oversize condition [0.080 in.

(2 mm) more than the original diameter]. Replace as required.

X

Hubcaps

Clean the

sight window. Check the center plug, mounting

ange, and ll plug for leaks and for proper installation.

Replace broken or damaged parts. Check the lubricant level

and add as required.

X

5-22 Y53-6047–2C (04/13)

Loading...

Loading...