Adjustment

14 - 60

● Bring the machine to the start of the end bartack stitches.

● Engage the stop motion device.

● Turn the drive pulley in its direction of rotation and observe the needle stitches.

● The machine switches off.

● Continue turning the drive pulley in its direction of rotation while observing the needle

stitches.

● Loosen screws 1 and move the trip 2 in accordance with the requirement.

● Tighten screws 1.

● Allow the machine to run at operating speed and carry out a check.

If another distribution of the reinforcing stitches is necessary due to operational

reasons, this can be achieved by moving the trip 2.

The reduction lug and the stop trip 2 are dependent on the transmission ratio.

These are to be readjusted if necessary when adjusting the feed gear pairing.

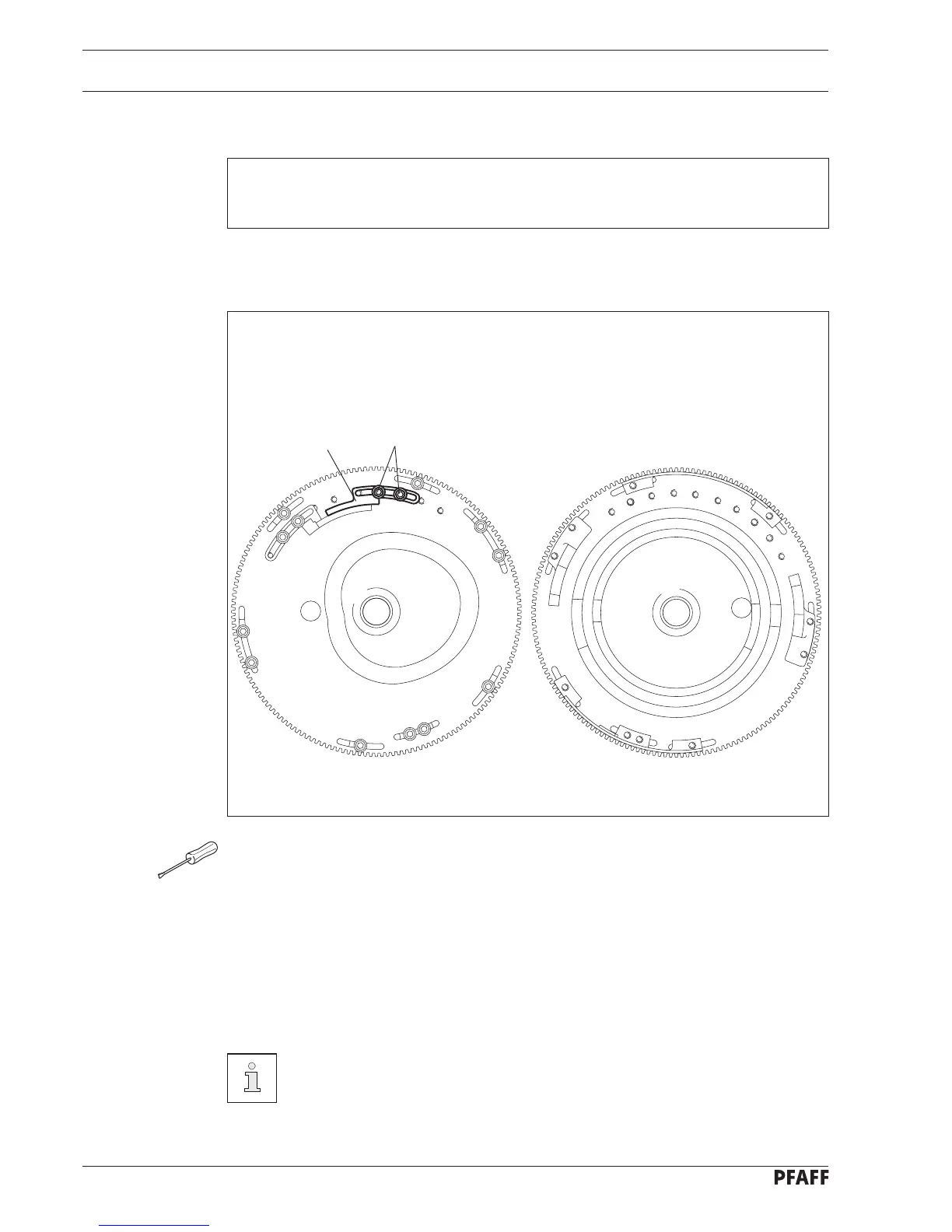

2

1

14.28 Switch off time

Requirement

The reinforcing stitches ( zero stitches ) must lie with one half on the seam end and one

half on the seam beginning.

Fig. 14 - 58

Loading...

Loading...