Care and maintenance

10 - 1

10.02 Cleaning

Switch off the machine!

Danger of injury due to unintentional starting of the machine!

Cleaning the hook area

● Clean hook area with a brush daily, in

continuous operation several times daily.

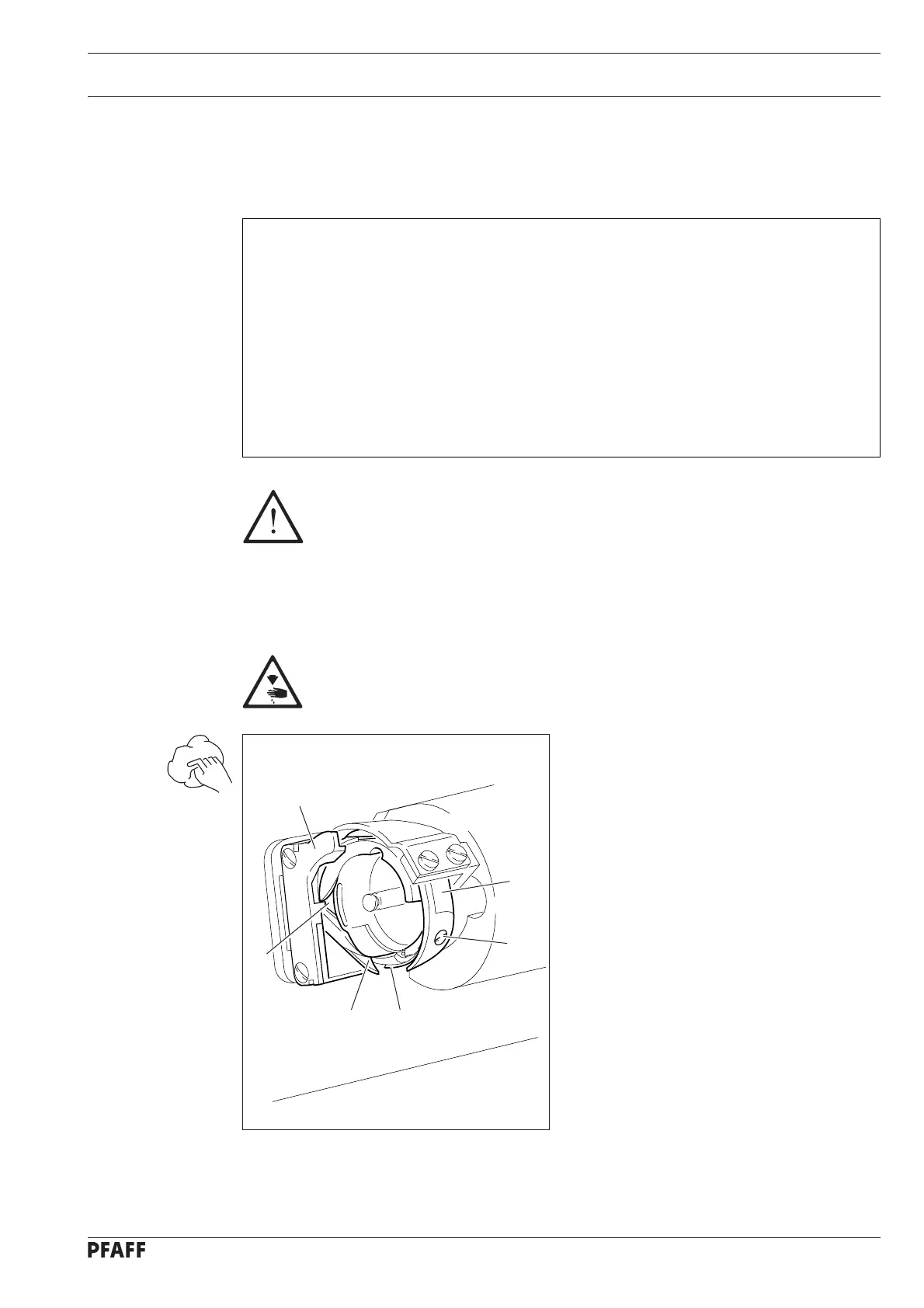

Cleaning the hook

● Open cylinder-bed cap.

● Set needle bar at its highest position.

● Remove top of bobbin case together with

bobbin

● Unscrew and remove bobin case position

stop 1.

● Remove screw 2 and take off hook gib 3.

● Turn balance wheel until point 4 is aligned

with point 5.

● Take out bobbin case and clean hook race

with petroleum spirit.

● When inserting the bobbin case, make

sure that the lug on the rear side of bobbin

case position stop 1 enters into groove 6.

● Screw on hook gib 3.

● Insert bobbin case and close cylinder-bed

cap

10 Care and maintenance

10.01 Care and maintenance intervals

Cleaning ............................................................ daily, in continuous operation several times

General oiling ................................................................................................... twice a week

Oil the hook ...................................................................... daily, before putting into operation

Oil needle-head parts ....................................................................................... twice a week

Lubricate the bevel gears .................................................................................... once a year

Check/adjust air pressure ................................................. daily, before putting into operation

Check water bowl of air filter/regulator ............................. daily, before putting into operation

The maintenance intervals in the table refer to the average machine running time

in single-shift operation.

If the machine running time is longer than this, it is advisable to shorten these

intervals.

3

2

Fig. 10 - 01

1

4

5

6

Loading...

Loading...