11 - 25

Adjustment

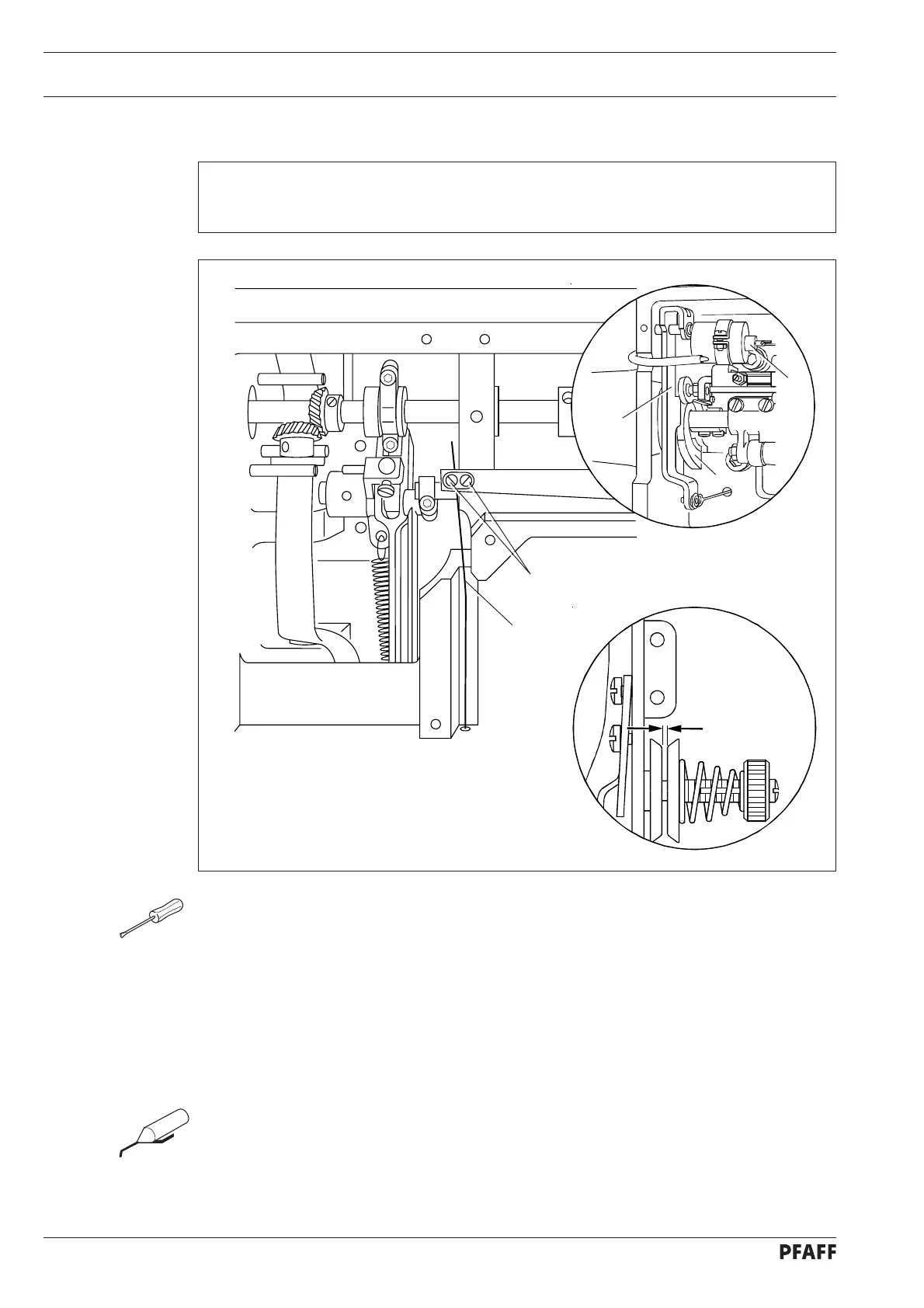

● Bring the sewing foot to rest on the needle plate using the hand lever.

● Bring the needle bar to its bdc by turning the handwheel and activate the magnet core 1.

● Turn the handwheel in its direction of rotation until the thread catcher has reached its

front point of reversal.

● Adjust the height of the transmission bar 2 (screws 3) so that the distance between the

tension disks is in accordance with the requirement.

● Finish the thread trimming process by turning the handwheel and bring the take up lever

to its tdc. In this position the needle thread tension must be fully activated.

● Finally, apply a light coat of grease to the surface of the release cam 4 and the tip of the

release lever 5.

11. 05.10 Triggering the needle thread tension

Requirement

With the tip of the release lever 5 at the highest point of the tension release cam 4, the

tension disks must be at least

5 mm apart.

Fig. 11 - 24

3

2

1

5

4

0,5 mm

Loading...

Loading...