14. Setting the lateral clearance to the right needle

Requirement:

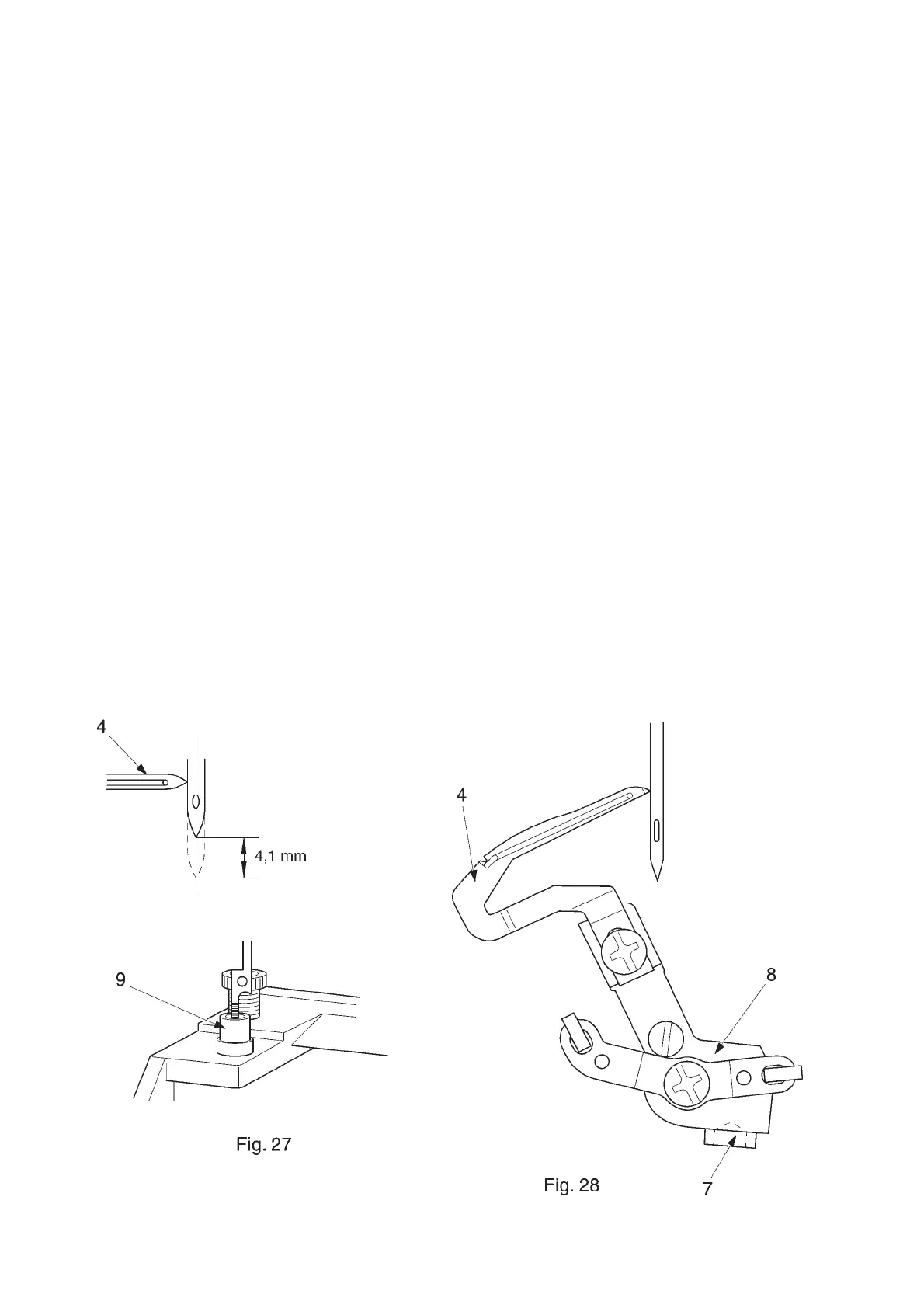

When the needle bar has moved 4.1 mm upwards from its lowest position (lower dead center), the loo-

per point 4 must be positioned as shown in figure 27.

Check:

● Move the needle bar to its lowest position by turning the handwheel.

● Place the adjustment gauge No. 93-415 503-21/555 in the needle bar bush 9.

● Turn the handwheel in the normal direction until the adjustment gauge (measurement D)

has moved almost “seven graduations” upward.

Graduation spacing = 0.6 mm x 6,83 = 4.1 mm

The looper point 4 must now be positioned on the edge of the left needle.

Setting:

● Move the needle bar to its lowest position by turning the handwheel.

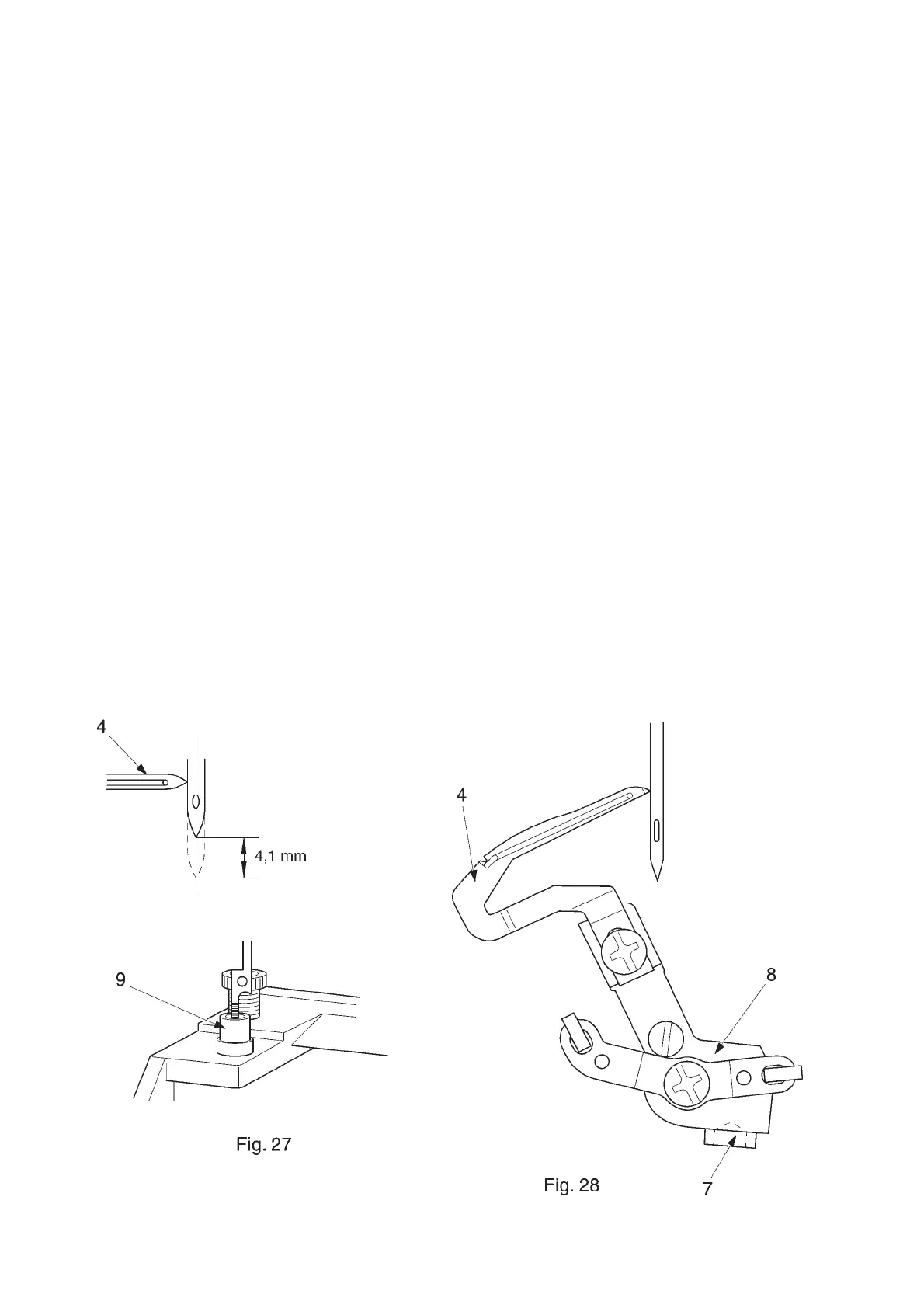

● Loosen the screw 7 of the looper lever 8 slightly (figure 28).

● Set the lateral clearance of 4.1 mm by pushing the looper lever.

● Tighten the screw 7 of the looper lever 8.

Test:

● As described under “Check”.

● The looper-to-needle clearance must checked or reset, as described under section 13

in the adjustment and repair instructions after having set the lateral clearance.

32

Loading...

Loading...