11

Requirements for adjusting the coverlock 4772

Requirement 1:

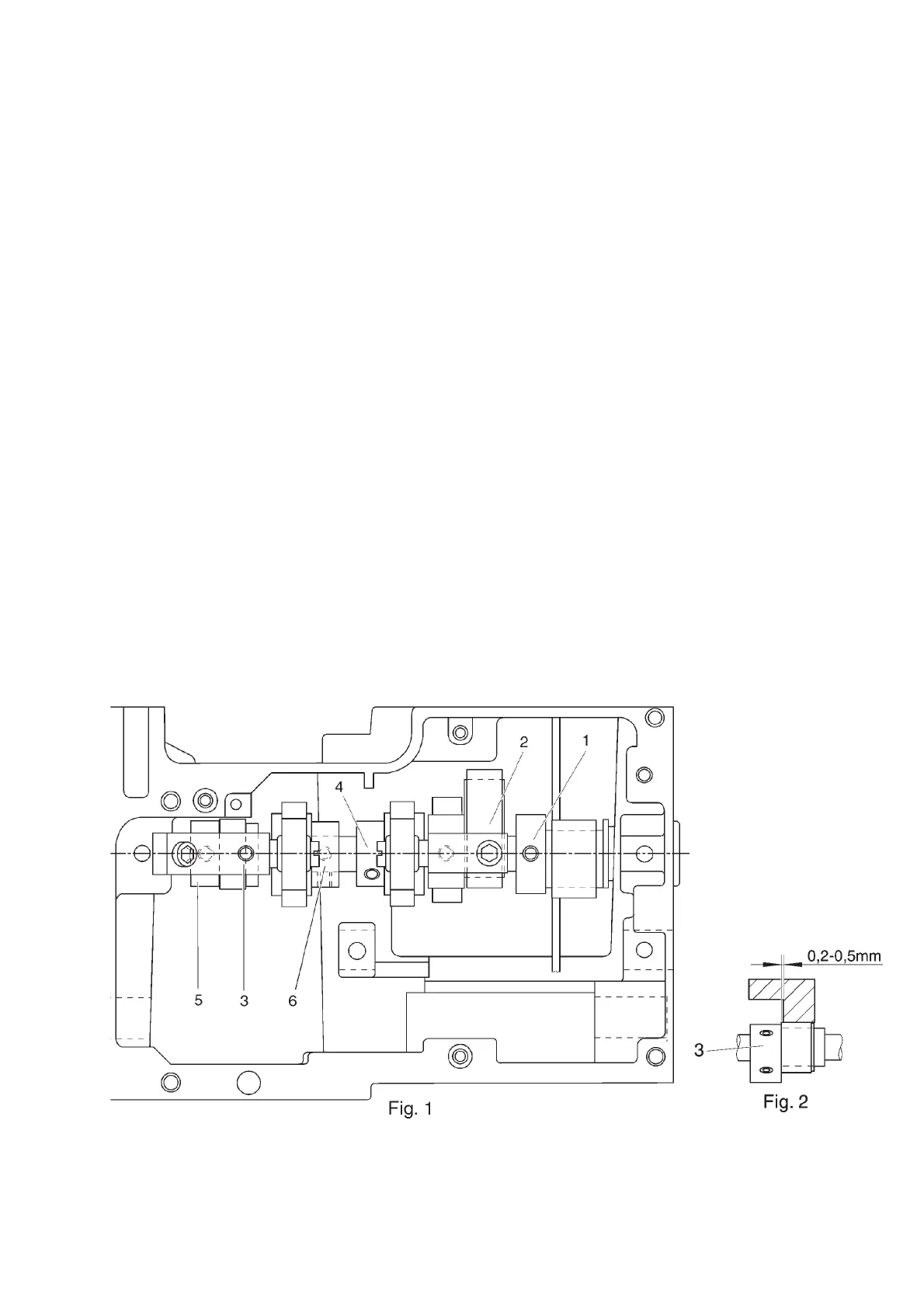

For the following eccentrics the first screw must be touching the surface of the main shaft in the normal

direction (figure 1):

Stroke eccentric 1

Drive eccentric 2 for the needle bar and blade drive

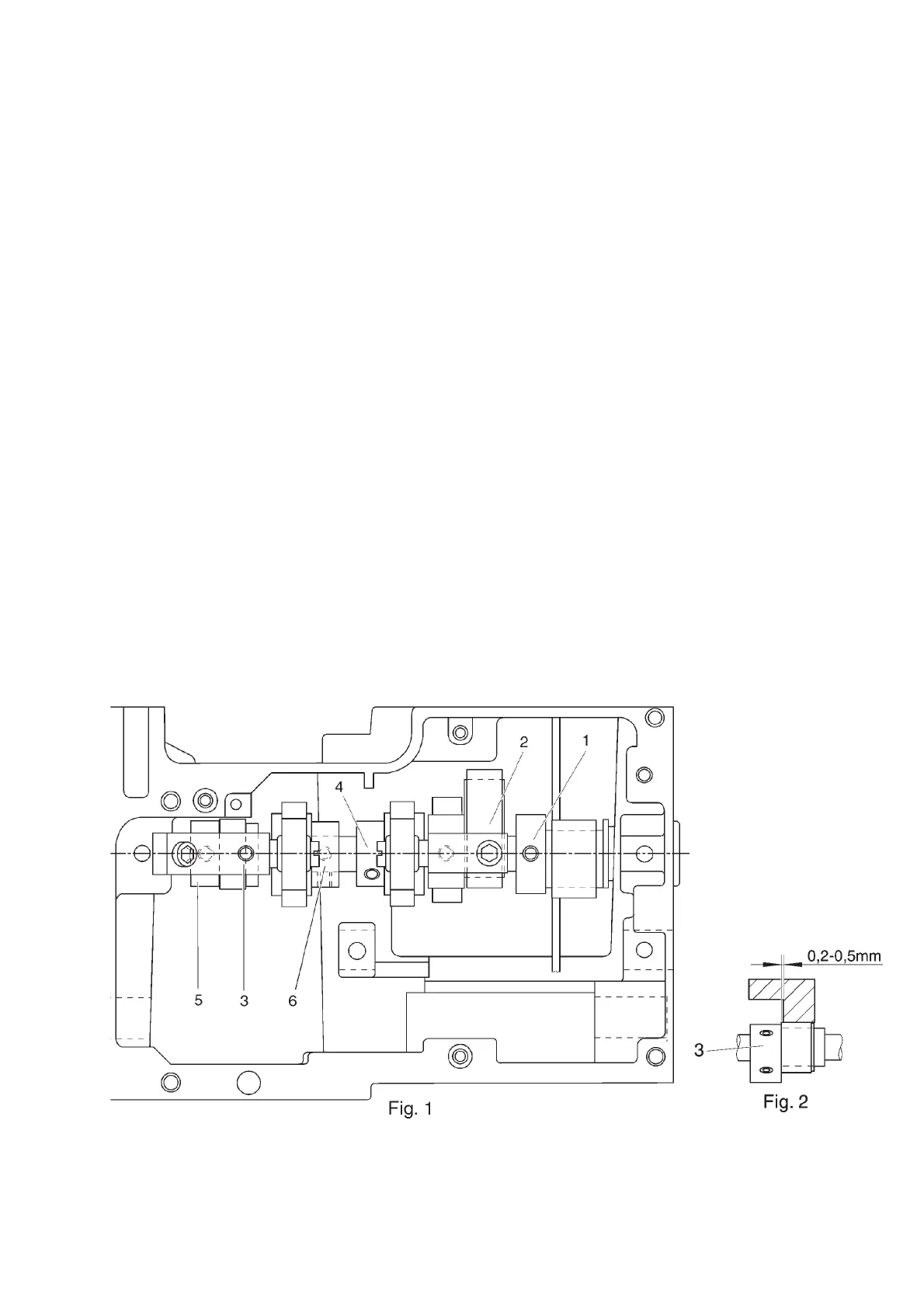

When in the starting position, the first screw of the lifting eccentric 3 must be aligned with the surface of

the main shaft in the normal direction.

Note:

The lifting eccentric 3 should be set so that there is a 0.2 to 0.5 mm clearance to the feed dog carrier

(figure 2).

Requirement 2:

When the needle is at its lowest point, the lower overedge looper must be at the left point of reversal,

and the right descending looper point approx. 5 mm beneath the needle plate. The two thread chain-

stitch looper must be at its right point of reversal.

To this end, the screws of the eccentrics 4 and 6 of the looper drives must be loosened. The eccentrics

must then be turned accordingly and the screws retightened.

The drive eccentric 5 for the ellipsoidal movement of the two thread chainstitch looper is set exactly at

the factory and must only be adjusted in urgent cases.

Loading...

Loading...