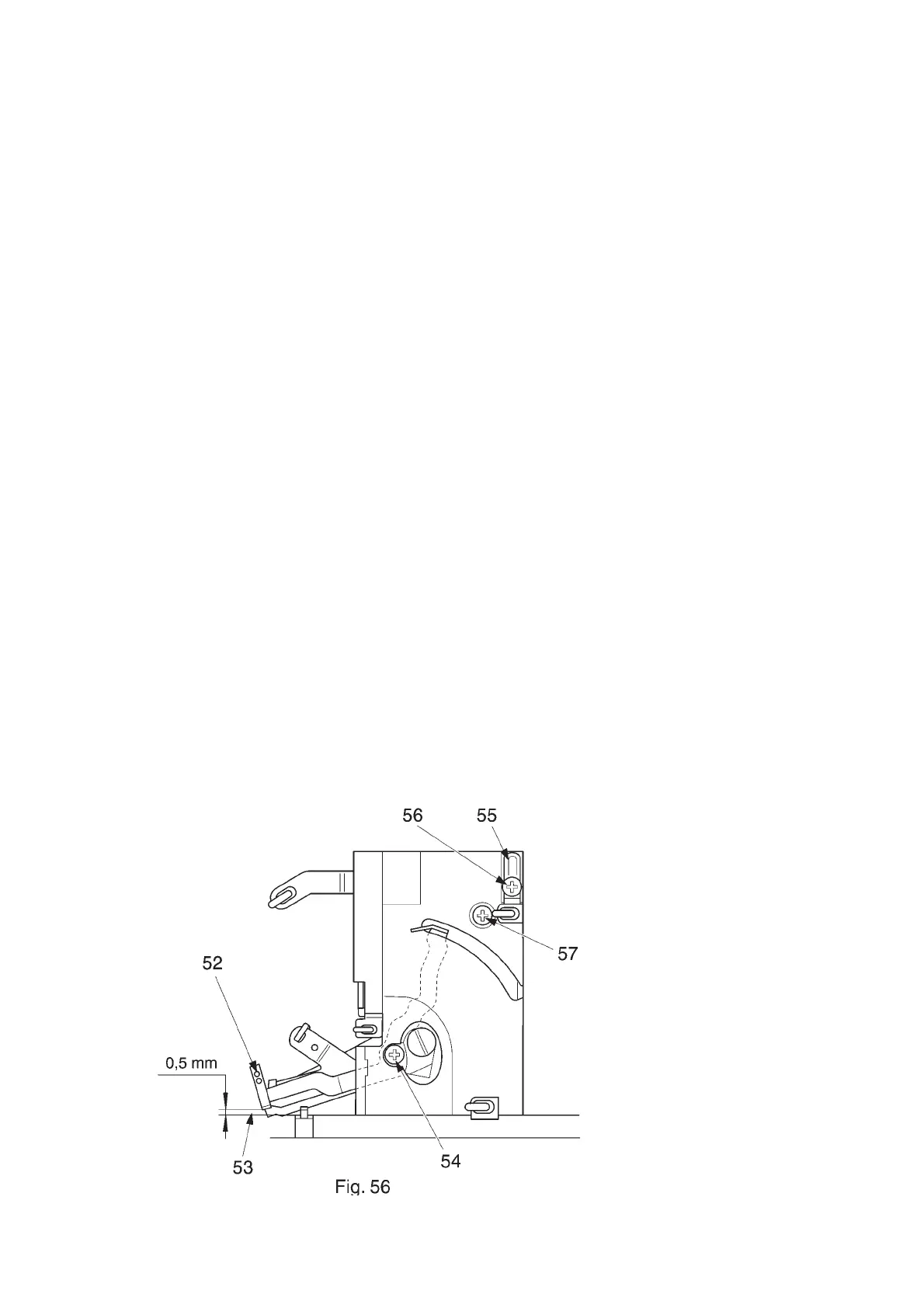

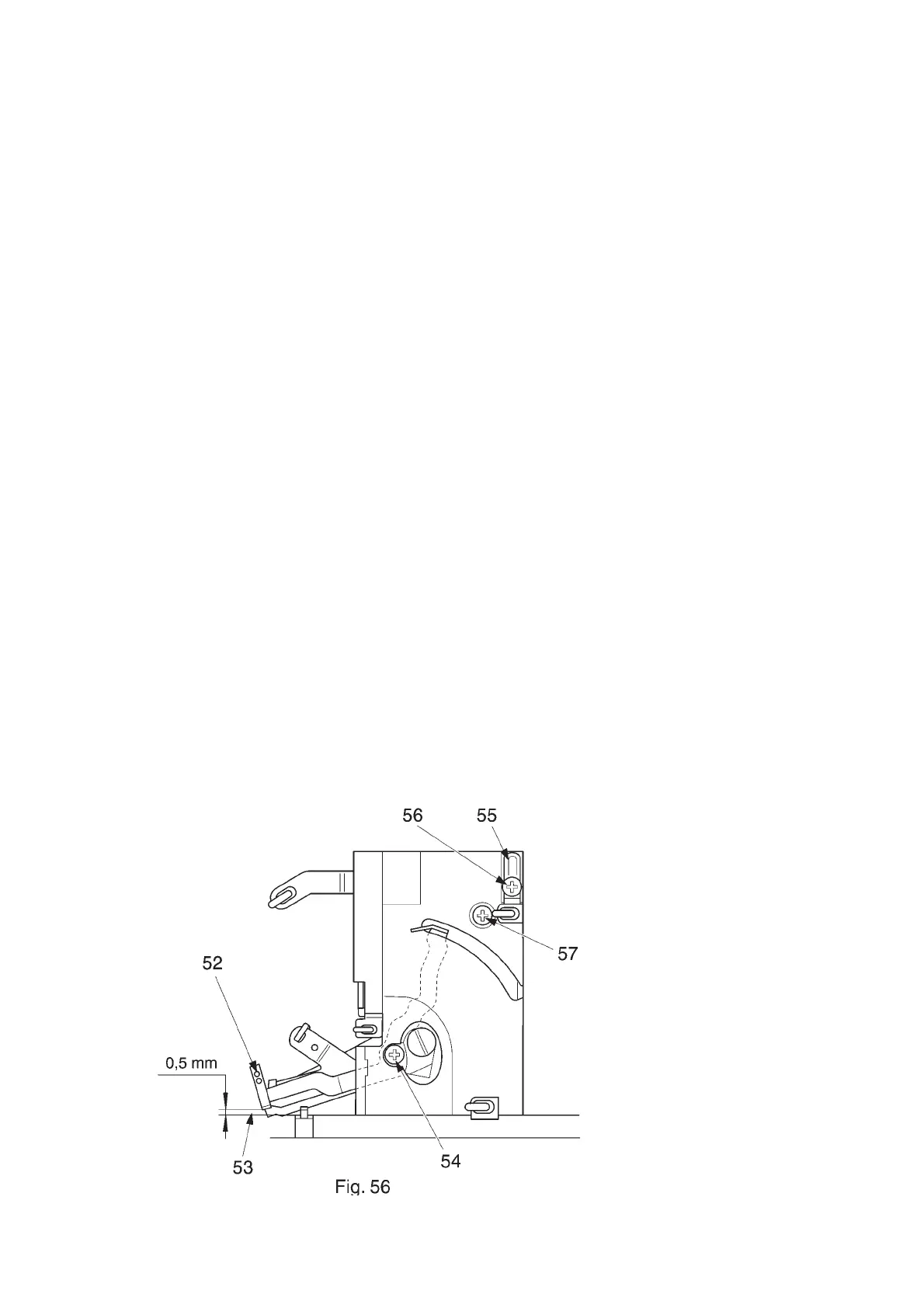

32. Setting the looper thread guides of the two thread chainstitch looper

Requirement 1:

When the upper overedge looper is at its lowest position, the large looper thread guide 52,

in its standard setting, should have a clearance of approx. 0.5 mm to the raised part 53 of the base

plate (figure 56).

Setting:

● Turn the handwheel in the normal direction, until the overedge looper is in its lowest position.

● Loosen the screw 54.

● Move large looper thread guide 52, until it clears the raised part 53 of the base plate by 0.5 mm.

● Tighten the screw 54.

Test:

● As desribed under “Requirement”.

Requirement 2

The small looper thread guide 55 should be set in the standard setting as seen in figure 56.

Setting:

● Loosen the screw 56

● Move the small looper thread guide until the eye of the looper thread guide is centered

to the fastening screw 57.

● Tighten the screw 56.

Test:

● As described under “Requirement”.

50

Loading...

Loading...