PG DRIVES TECHNOLOGY AC TRACTION – INSTALLATION

5.2 Battery and Motor Wire Size and Type Selection

The wiring arrangement used on a particular vehicle can greatly affect the current carrying capacities of individual wires.

Ambient temperature, grouping and wire length can all significantly de-rate cable performance and other factors such as

vehicle duty cycles and airflow should also be taken into consideration when selecting vehicle wiring.

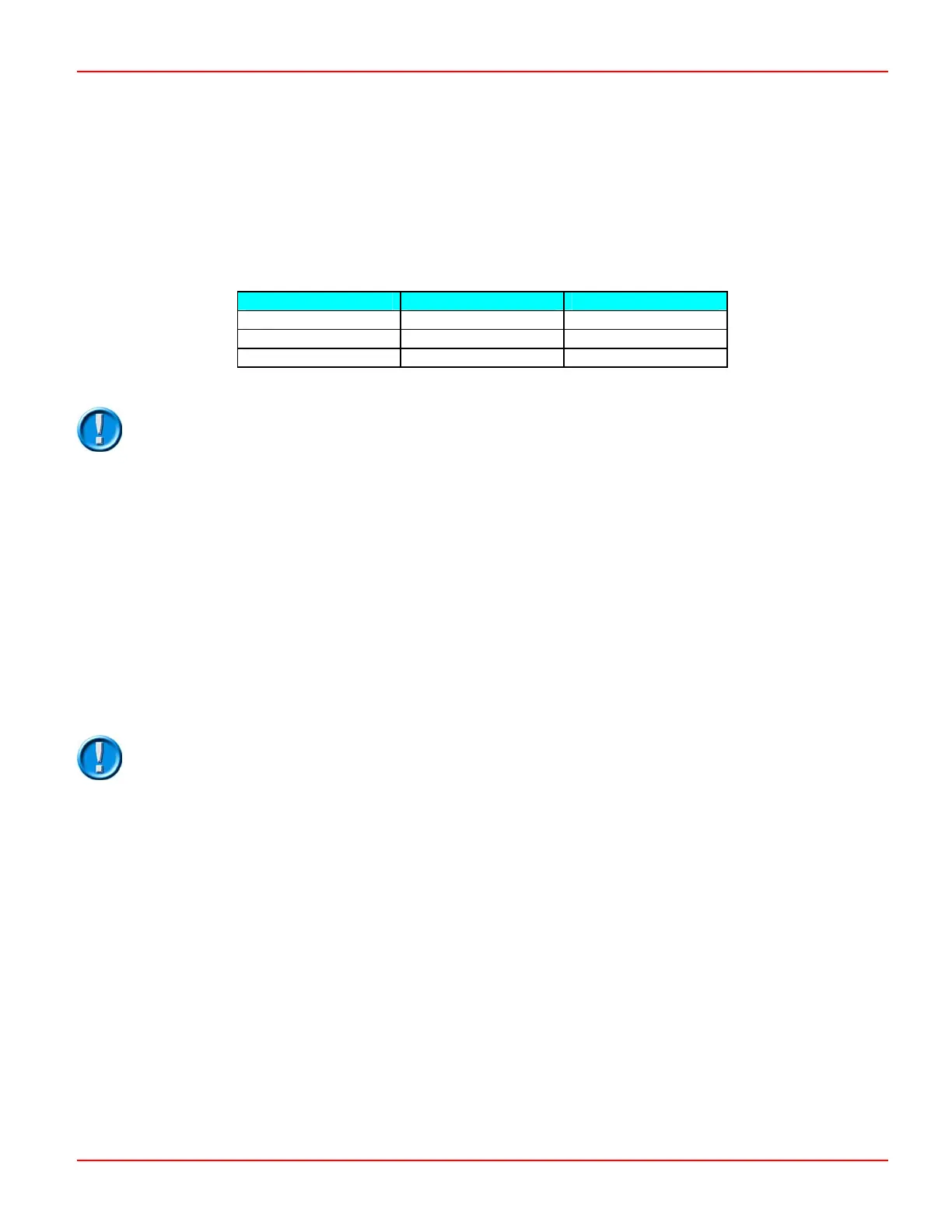

PGDT recommends the use of BS6231 (UL 1015, 1028, 1283 or 1284 dependent on wire gauge), Tri-rated wire due to its superior

flexibility and 90/105°C temperature rating. The table below shows the minimum recommended wire sizes for the various

connections on the Sigmadrive controllers.

Frame Size Motor Battery

Small 16 mm

2

16 mm

2

Medium 35 mm

2

35 mm

2

Large 70 mm

2

70 mm

2

It is the responsibility of the vehicle manufacturer to ensure that the vehicle’s wiring arrangement

is suitable for the intended application, and complies with all necessary standards that are

dictated by the relevant approvals of regulatory organizations. PGDT accepts no liability for

losses of any kind arising from an inappropriate wiring arrangement.

5.3 Battery and Motor Connection Crimps and Tooling

Good quality crimping is essential in ensuring the long-term reliability of the vehicle’s electrical system. Poor quality crimps may

initially appear satisfactory, but can deteriorate over time, ultimately causing the vehicle to break down. For the battery and

motor connections, the use of AMP

®

AMPower III or Solistrand copper tube leg terminals is recommended. It is absolutely vital

that the selected crimp terminal is designed to be used with the wire size and type being used.

It is also vital that for the selected crimp terminal the correct tooling is used for its installation onto the wire, and that the

procedure for doing so is followed correctly. Contact the crimp terminal manufacturer to ensure that the tooling employed is

suitable for use with the chosen combination of wire and crimp terminal.

If insulated crimps are used, ensure the insulation is firmly pushed into place. If uninsulated crimps are used, it is recommended

that heatshrink or similar sleeving is used to insulate the barrel of the crimp terminal.

Ensure that only fully trained and skilled operators perform the crimping procedure and that the

instructions provided by the crimp terminal manufacturer are followed. PGDT accepts no liability

for losses of any kind if the recommendations made in this section are not followed.

5.4 Control Connections

The low current control connections on the Sigmadrive are via Molex® SMD Micro Fit 3.0 Series connectors. These connectors are

labeled as A, B and C on the cover of the controller and provide the following functions.

A 16-way Vehicle Interface Connector

B 8-way Communications Connector

C 6-way Motor Feedback Connector

5.5 Control Connection Wiring

Use 0.5mm

2

/18AWG wire gauge for all control connections. It is also recommended that Tri-rated wire with a 105ºC insulation

rating is used.

SK79646-01 17

Loading...

Loading...