It’s now necessary to clean the grinding paste out. Begin by marking the blade and the

hub. To make sure you don’t reassemble the blades 180 degrees out and upset the

balance, insert a grub screw with Loctite 243 180 degrees on the opposite side of blade

levers.

Grease the internals of the prop. Reassemble it and mount it back on the stand. Double

check the blade angles and insert the 4 bolts to lock the hub. Also insert the grub screws

into the adjusting rings on the blade ends.

Mount the spinner and mark it for blade movement. Determine how much to grind off

with Dremel for appropriate clearance.

Now remount and check again. If the propeller is out of balance you can apply some black

nitro spray paint to the lighter blade for balance. In really bad cases you an use a small

nut and bolt. Firstly use tape to hold it in position and check several locations for the

best position. When checking for balance, tap the stand to vibrate the bearings to help

the propeller turn.

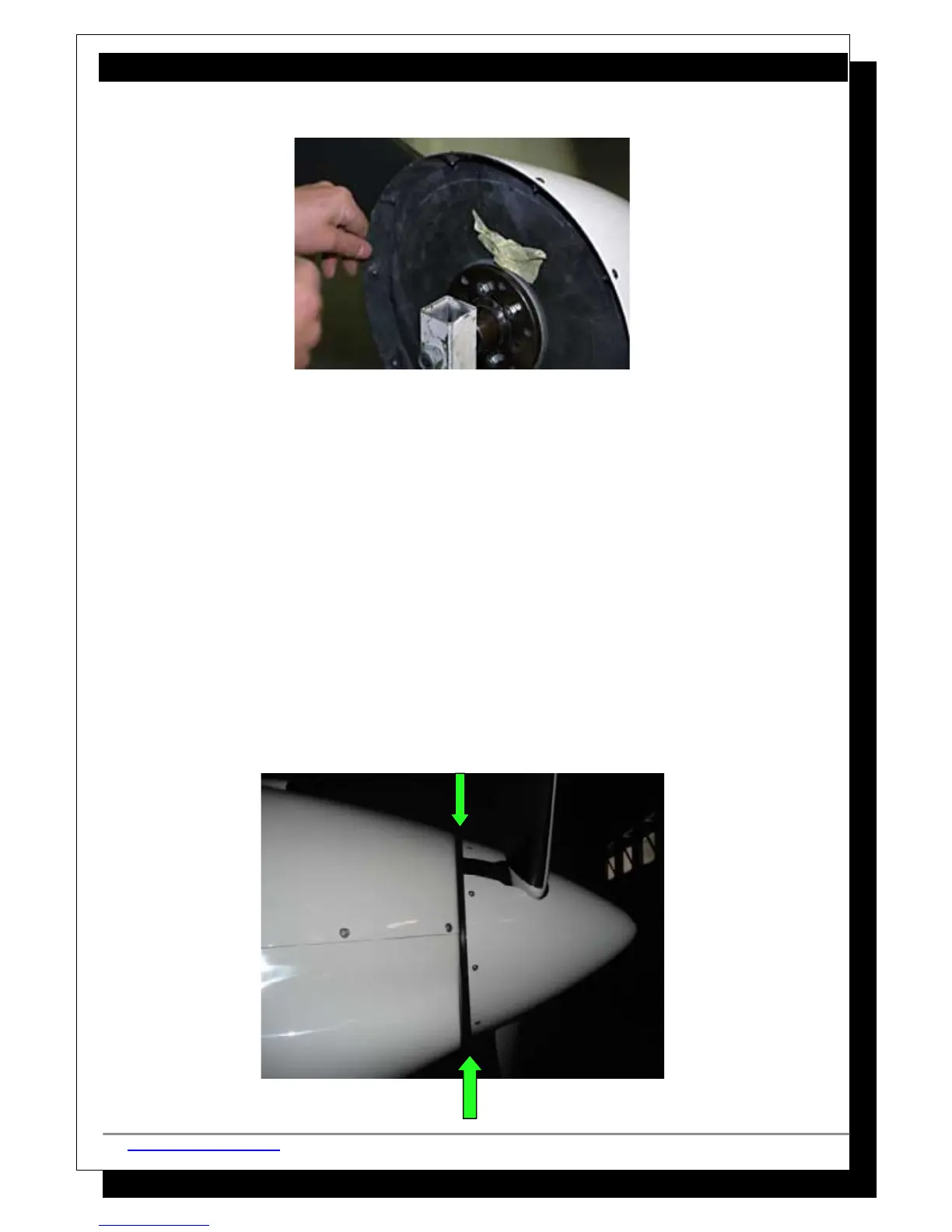

Once the propeller is properly balanced, assembled and mounted, check to see that the

spinner is nicely aligned with the engine cowls. The profile created by the cowls and the

spinner, as seen from the side of the aircraft, should be continuous. There should be no

step between the cowl and spinner profiles. If there is, this could have a negative impact

on the aircraft's aerodynamic properties.

http://www.pipistrel.si © Pipistrel Release March 2009 © Page 195 of 267

Loading...

Loading...