3

9850045 R01 - 2020-2021 RANGER 1000 Service Manual

© Copyright Polaris Inc.

3.67

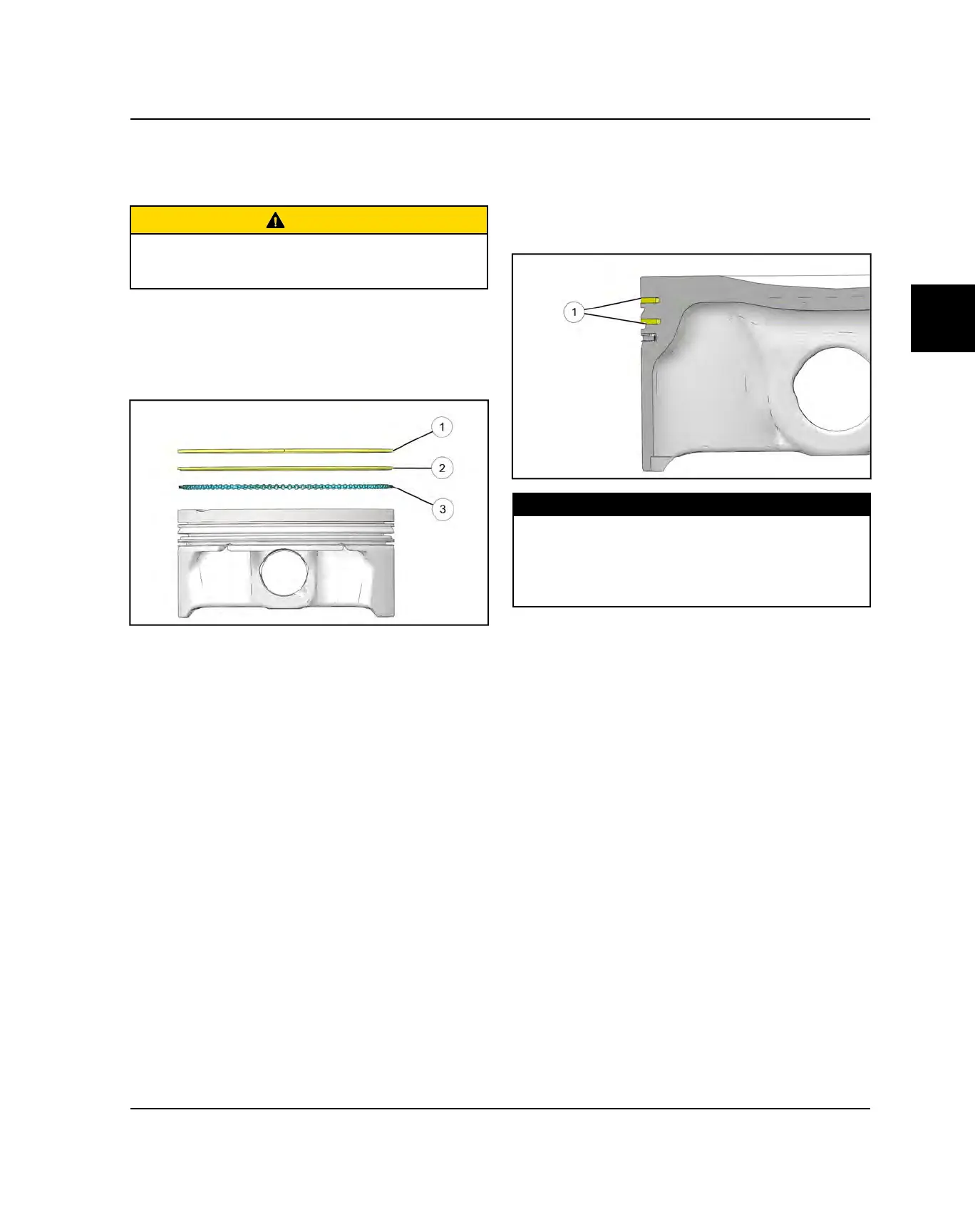

PISTON RING REMOVAL

1. Carefully remove top compression ring

q

by hand or

using a ring removal pliers (PV-43570-1).

CAUTION

DO NOT expand the ring more than necessary to

remove it from the piston or the ring may break or lose

radial tension.

• Piston ring pliers: Carefully expand ring and lift it

off the piston.

• By hand: Placing both thumbs on the ring ends,

spread the ring open and push up on opposite side.

Do not scratch ring lands.

2. Repeat procedure for second compression ring

w

.

3. The oil control ring

e

is a three piece design

consisting of a top and bottom steel rail and a center

expander section. Remove top rail first, then bottom

rail, then the expander.

PISTON RING TO GROOVE CLEARANCE

INSPECTION

1. Measure piston ring to groove clearance

q

by

placing the ring in the ring land and measuring with a

thickness (feeler) gauge. Replace piston and rings if

ring-to-groove clearance exceeds service limits.

MEASUREMENT

Piston Ring to Groove Clearance:

Top / Second Ring

.0007 - .0023" (0.020 - 0.060 mm)

Service Limit:

.0047" (0.12 mm)

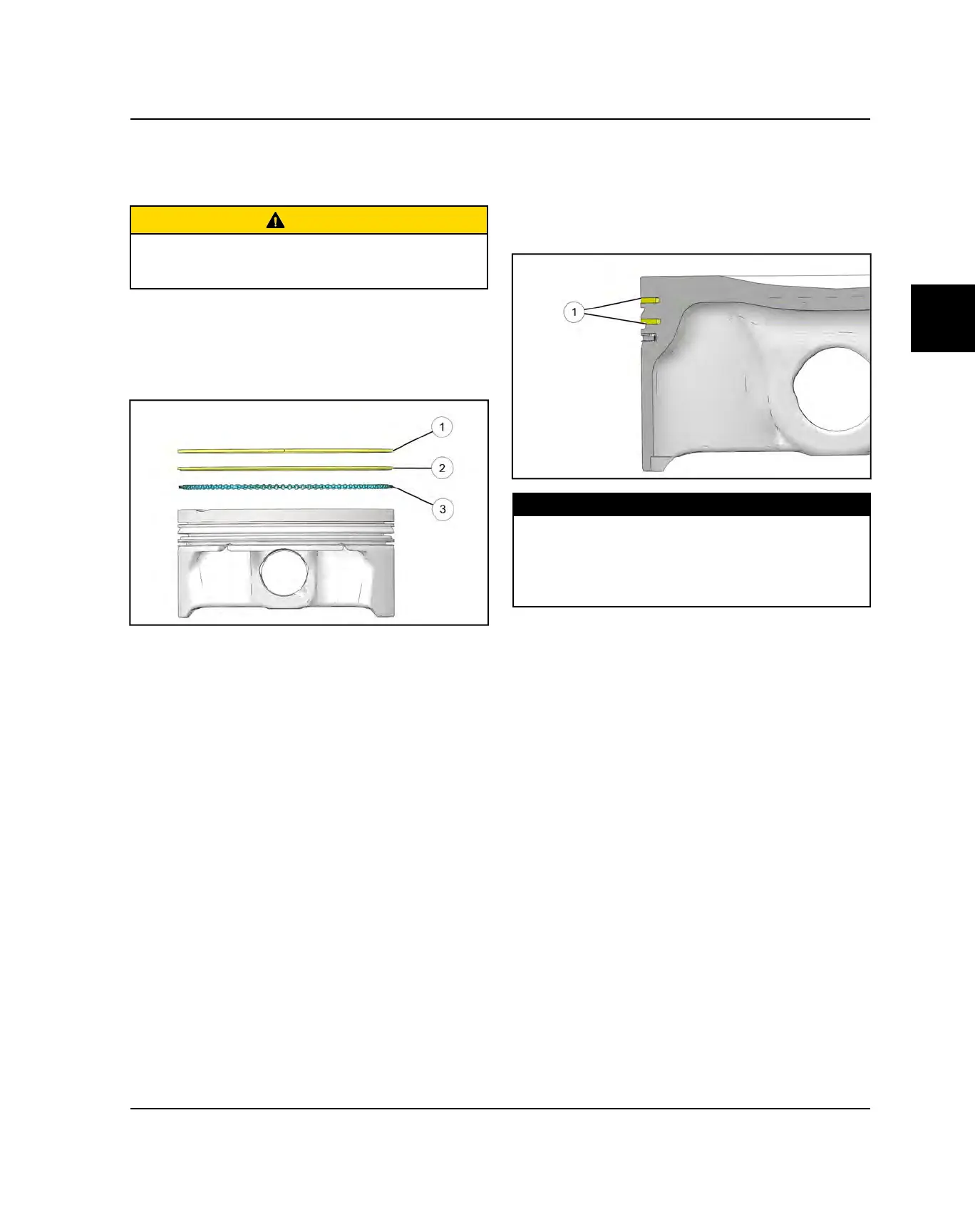

PISTON RING INSTALLED GAP

1. Place each piston ring

q

inside the cylinder

w

. Use

the piston to push the ring squarely into cylinder, as

shown below.

ENGINE / COOLING / EXHAUST

Loading...

Loading...