16 MAN. PS 254 EN – Ind. 2

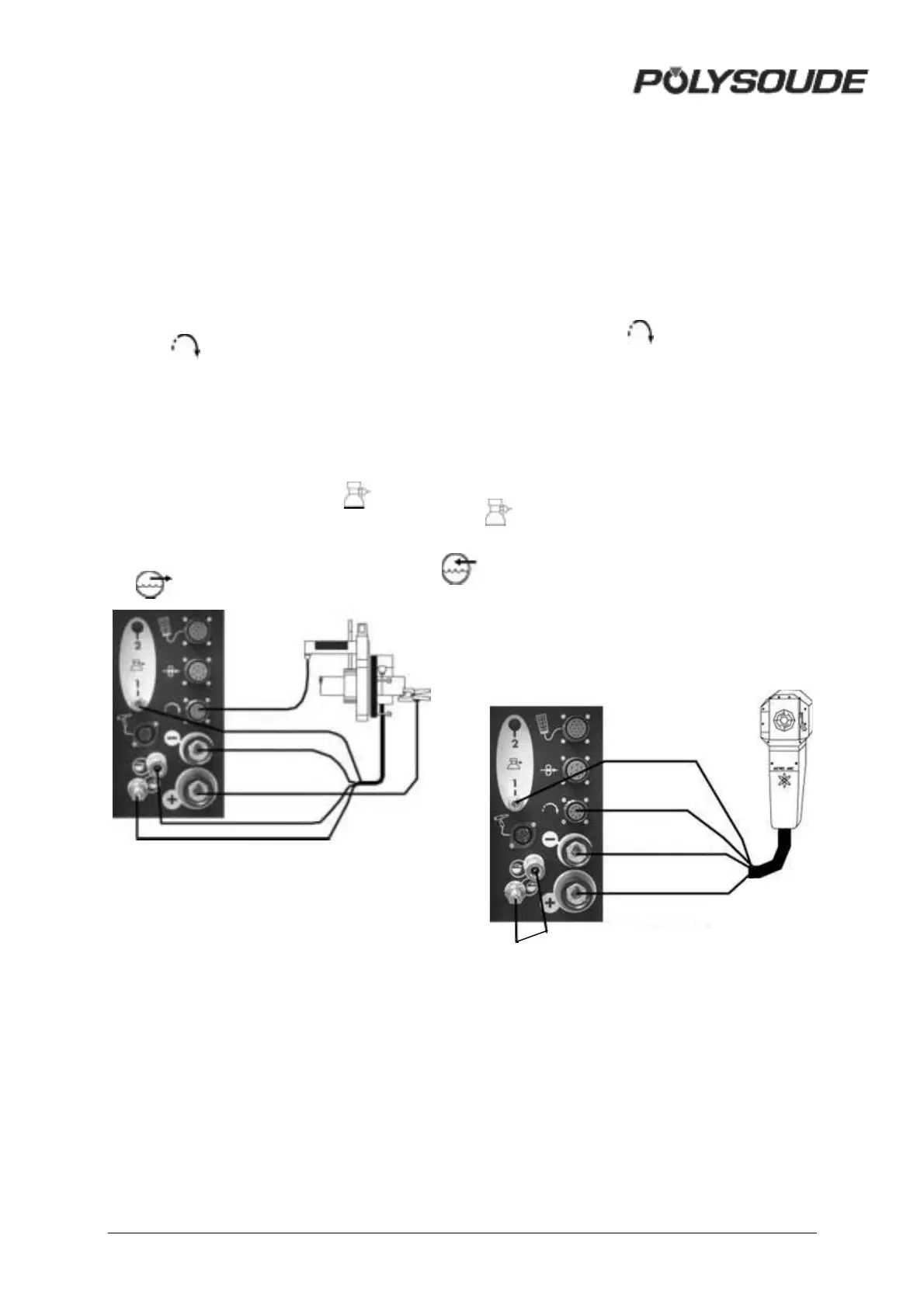

! Connection of the current return cable

Connect the current return conductor cable

onto the "+" terminal marked by a red ring.

Connection is made with a quick connector, by

a short rotation to the right. Connect the other

end of the cable to the workpiece, as close as

possible to the joint to be welded, in an area

free from grease and oxide.

! Connection of the rotation motor cable

Join the cable on the "Rotation" connector

(symbol ). Make sure that the securing ring

is properly tightened, otherwise the system

may not function correctly.

! Connection of the torch shielding gas

hose

Connection is made with a quick push-type self

sealing coupling situated at the connection

plate of the power source (symbol ).

! Connection of the coolant circuit

Connection is made by 2 quick push type self

sealing couplings on the front view (symbols

and ).

Fig. 2.6 : Connection of an MU welding

head or a TP/TS welding head

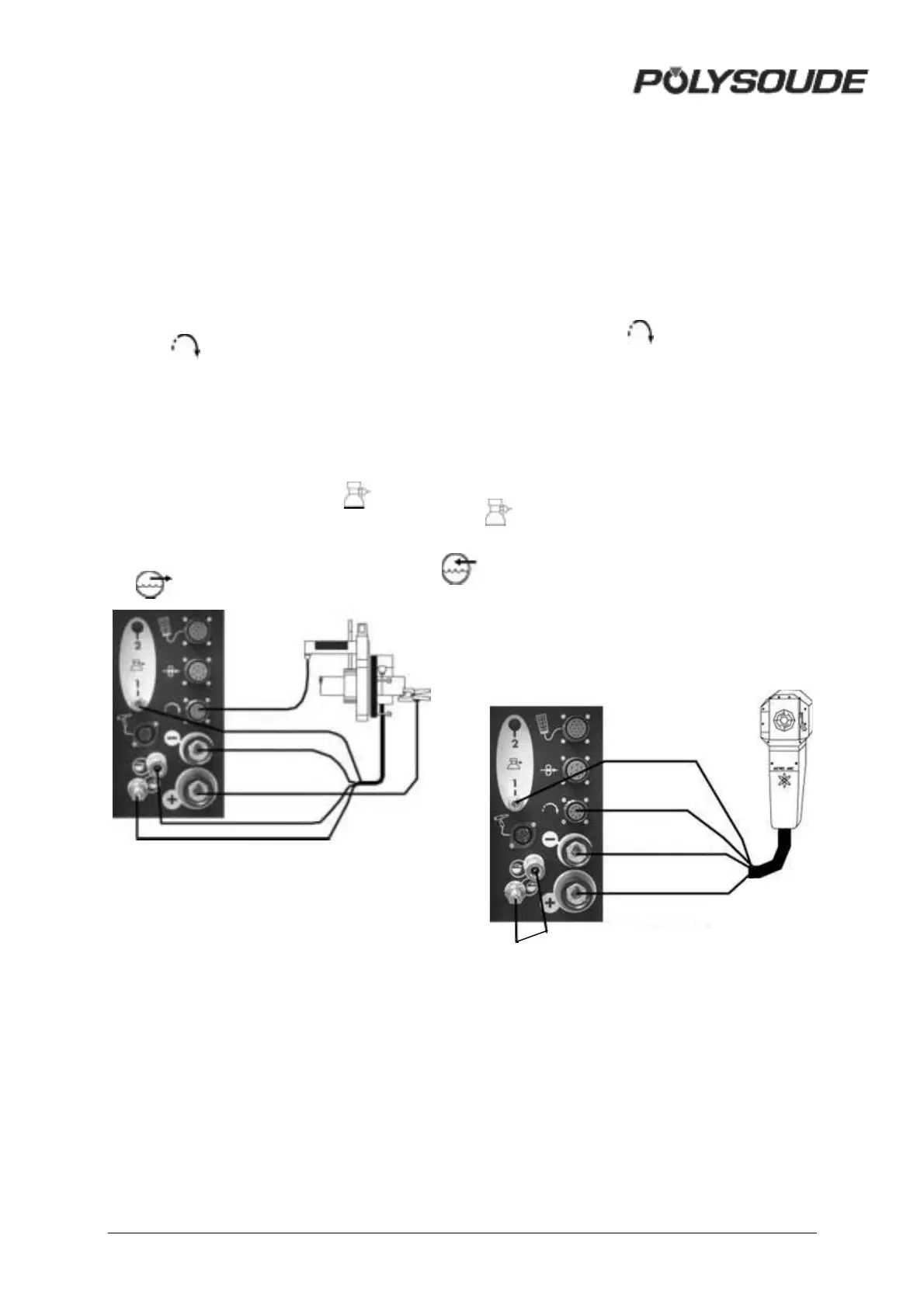

2.3.3. Connection of an air cooled closed

chamber welding head

Connection of an air cooled closed chamber

welding head

! Connection of the electrode current

cable

Connect the current cable on the "-" terminal

with the quick connector, locking it by a short

rotation to the right. This cable is not indicated.

! Connection of the current return cable

Connect the current return conductor cable

onto the "+" terminal marked by a red ring.

Connection is made with a quick connector by

a short rotation to the right. This cable is

indicated red.

! Connection of the rotation motor cable

Connect the cable on the "Rotation" module

connector (symbol ). Make sure that the

securing ring is properly tightened, otherwise

the system may not function correctly

! Connection of the torch shielding gas

hose

Connection is made with a quickpush type self

sealing coupling disconnect fitting situated at

the bottom left hand corner of the front panel of

the PS 254 (symbol

").

! Connection of a bipass plug for the

coolant circuit security for use with air

cooled welding heads.

It is necessary to introduce the bipass plug to

isolate the cooling circuit security in order to

avoid a continuously detected fault.

Fig. 2.7 : Connection of an air cooled

closed chamber welding head

Torch rotation

connection

Gas coupling

Electrode connection

Workpiece connection

Water coupling

Water coupling

Gas coupling

Torch rotation connection

Electrode connection

Workpiece connection

Shunt supplied with H heads

Loading...

Loading...