MAN. PS 254 EN – Ind. 2 79

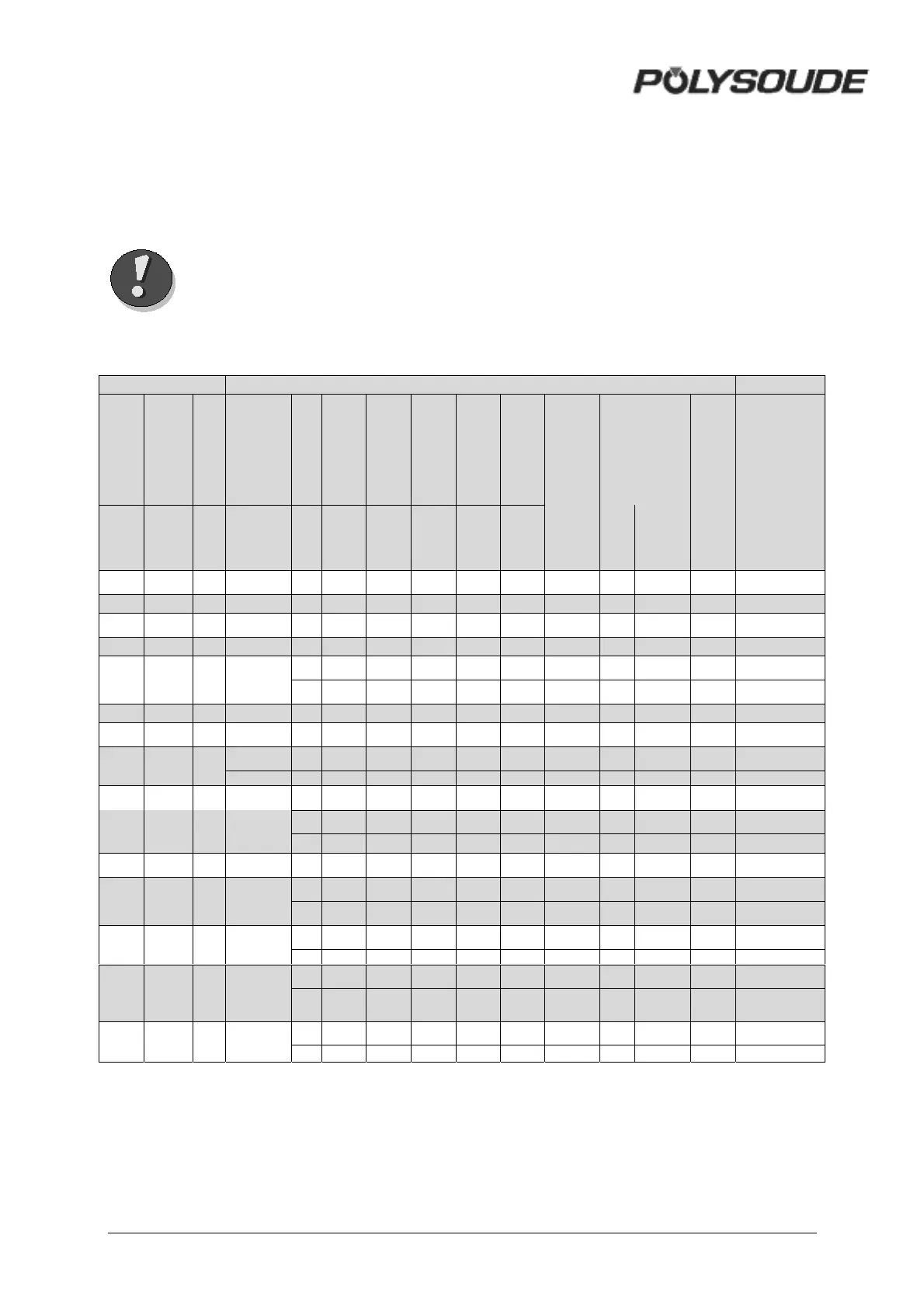

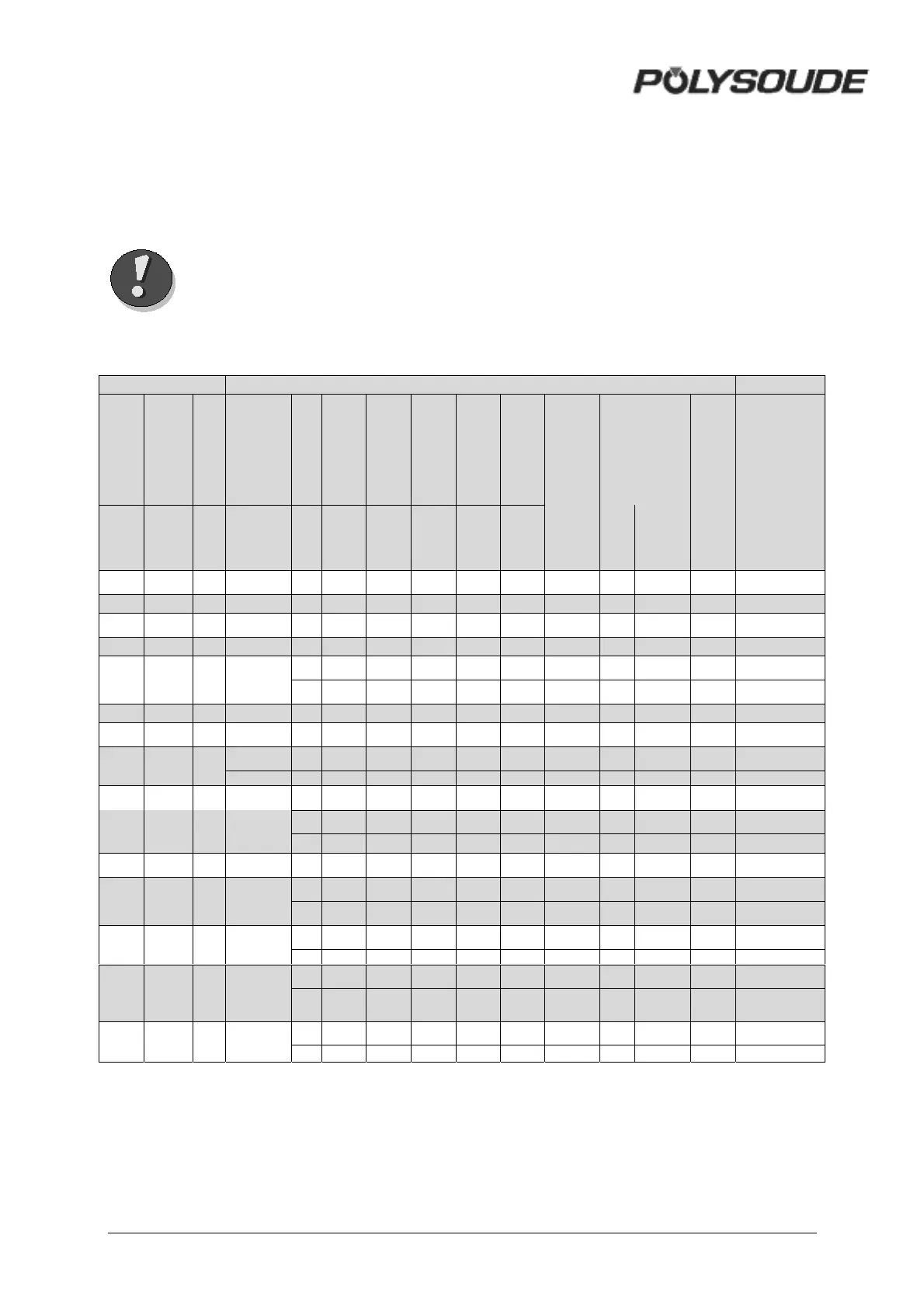

5.1.2. MU open welding heads with filler

wire

Warning For some welds the distance

electrode-workpiece has to

be modified at the end of the

cycle when the beginning of

the seam is overwelded.

These programs are marked

with a star in the last column

of the set-up before welding.

Tubes to be welded

Set-up before welding Range

Material

Ø OD

Wall thickness

Preparation

Ø Electrode

Tip angle

Nose

Distance

electrode/work

piece

Wire angle

Distance

électrode/wire

mm

mm

mm

degrees

mm

mm

degrees

mm

Start position

Layer

Built-in program number

Adjust at the end of cycle

PS 254

Stainless

33.7 3.2

V 37.5° 0.4

mm nose

2.4 40 0.3 2.5 25 3 12 H 41 *

X

Stainless

51 1.8

Square-butt

2.4 40 0.3 2.5 20 3 12 H 43

X

Stainless

51 3

V 37.5° 0.2

mm nose

2.4 40 0.3 2.5 25 3 10H30 44 *

X

Stainless

60.3 2.5

Square-butt

2.4 40 0.3 2 20 2.5 10H30 46 *

X

2.4 40 0.3 2 25 3 10H30 47 *

X

Stainless

60.3 4

J 30°

0.9 mm

nose 1.5

mm land

2.4 40 0.3 3 20 3.5 12 H 2 48

X

Stainless

114.3 2.5

Square-butt

2.4 40 0.3 2.5 20 3 12 H 51 *

X

Stainless

114.3 3

Square-butt

2.4 30 0.3 2 25 2.5 10H30 52 *

X

1 53

X

Stainless

168 4

2 54

X

Mild steel

25 3.2

V 37.5° 0.2

mm nose

2.4 40 0.2 2 25 2 10H30 56 *

X

2.4 40 0.2 2 20 2.5 10H30 1 57 *

X

Mild steel

38 3

V 37.5° 0.2

mm nose

2.4 40 0.2 2.5 20 3 12 H 2 58

X

Mild steel

51 3

V 37.5° 0.2

mm nose

2.4 40 0.2 2 15 2.5 10H30 59 *

X

2.4 40 0.2 2 30 2 10H30 1 61 *

X

Mild steel

51 4

J 30° 1.4

mm nose

1.5mm land

2.4 40 0.2 2.5 20 3 12 H 2 62

X

2.4 40 0.2 1.5 25 2.5 10H30 1 63 *

X

Mild steel

60.3 3

V 37.5° 0.2

mm nose

2.4 40 0.2 2.5 20 3 12 H 2 64

X

2.4 40 0.4 2 35 1.5 10H30 1 65

X

Mild steel

88.9 4

J 30°

1 mm nose

1.5 mm

land

2.4 40 0.2 2 10 2.5 12H 2 66

X

2.4 40 0.2 1.5 25 2 10H30 1 67 *

X

Mild steel

114.3 3.9

V 37.5° 0.2

mm nose

2.4 40 0.2 3 10 3.5 12 H 2 68

X

Loading...

Loading...