MAN. PS 254 EN – Ind. 2 53

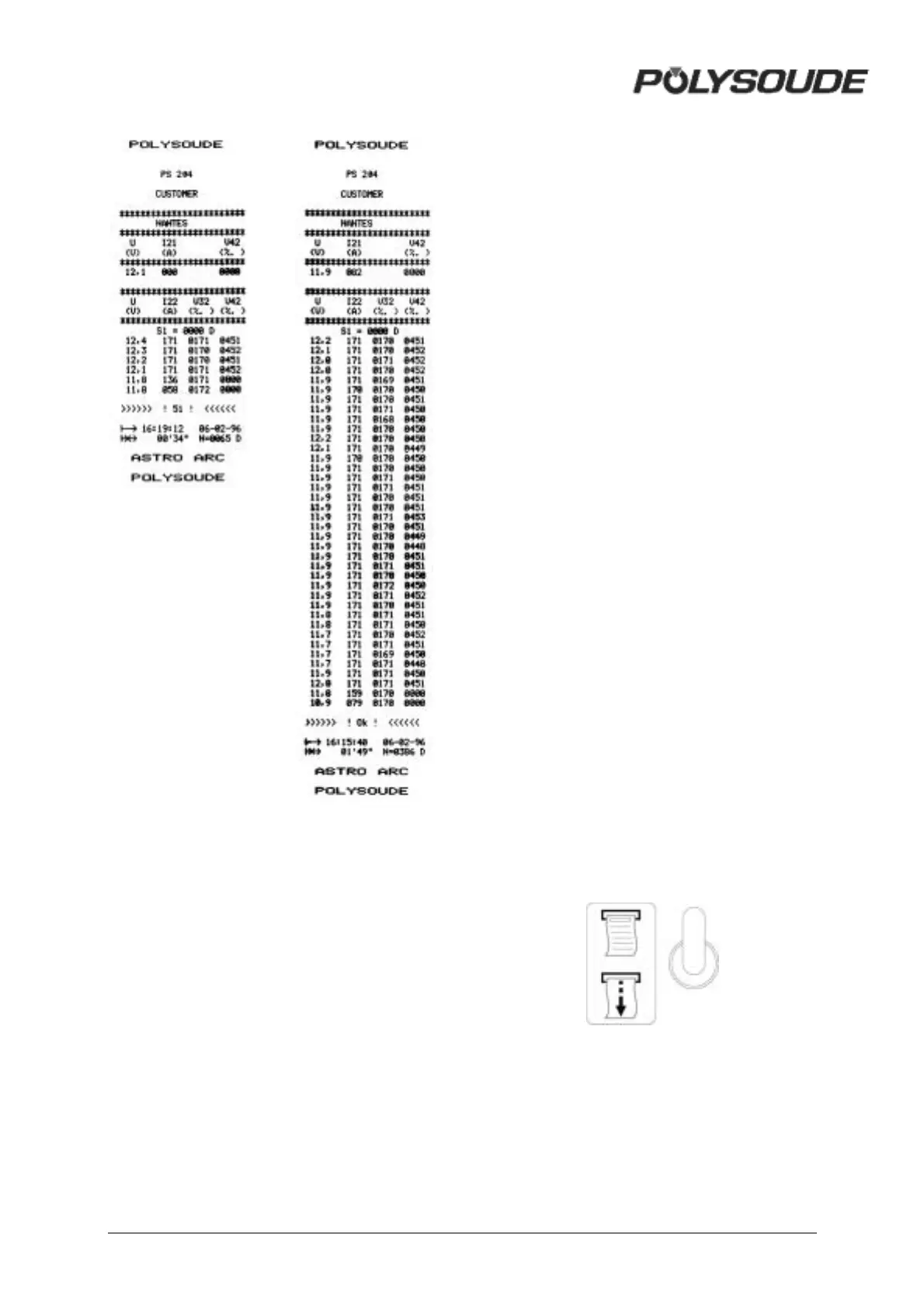

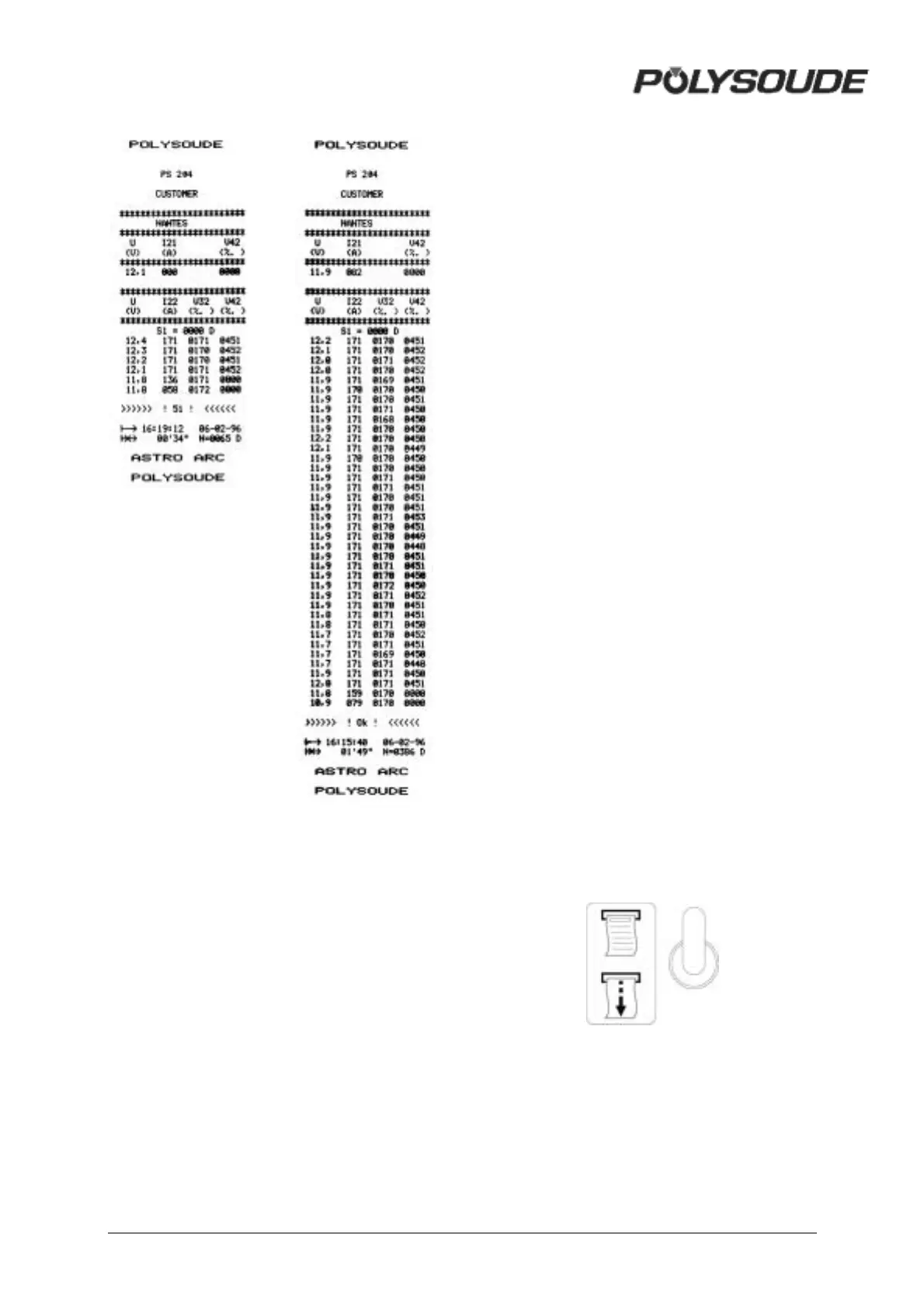

Fig. 3.9 Fig. 3.10

Fig. 3.9 : Example of a weld cycle report

with manual downslope, denoted by error

code >>>> ! 52 ! <<<<

Fig. 3.10 : Example of a weld cycle report

with a normal cycle end, denoted by

>>>> ! OK ! <<<<

3.4.5. End of welding cycle

! Normal end of welding cycle

In the case of a normal end of the welding

cycle, the indicator on the remote control

pendant extinguishes. The power source is

now ready to start a new cycle.

N.B.: welding head that is fitted out with an

"open head" position sensor will be

automatically positioned in this way at the

regular end of a cycle.

! Weld cycle report

At the end of every weld, you can print a weld

cycle report indicating periodically the real

values of the main weld parameters. This

listing is provided automatically if

preprogrammed. After a weld cycle in

simulation mode, no weld report can be given.

The weld cycle report consists of:

• The name of your company.

• The program name.

• Values of periodically taken

measurements of the voltage, amperage,

rotation speed and wire speed during the

cycle.

• Reason for stop ("OK" for a normal cycle

end, if not, error code).

• Time of cycle start.

• Date of weld.

• Length of cycle.

• Tungsten location.

! Reprint of a weld cycle report

If the printout of a weld cycle report fails, for

example because of a lack of paper, it is

possible to restart it by pushing the switch SY

29 situated at the right of the printer upwards.

Fig. 3.11 : Printer switch

3.4.6. Manual weld cycle stop

! Manual weld cycle stop with downslope

The manual downslope button BT 6 on the

remote control pendant starts the programmed

Loading...

Loading...