76 MAN. PS 254 EN – Ind. 2

5. APPENDIX

5.1. Built-in programs

The Polysoude weld lab developed these

programs for mild steel and stainless steel

tubes. Starting from frequent applications they

represent the base to work out rapidly your

own weld programs. Please look for a program

close to your application in order to modify it.

Before you can use such a built-in program

you have to copy it in one of the 16 user

program places in the memory of the power

source (for detailed information, see

Programming Manual). Afterwards you can

modify the program to fit your special

application.

For all applications, Argon is used as shielding

gas. The programs are listed in function of the

welding head (closed chamber, MU III, or

TS/TP), the material (mild steel or stainless

steel), the diameter and the wall thickness of

the tubes to be welded. In case of tube to tube-

plate welds, a difference is made between

"flush" and "protruding" tubes.

Warning If multipass welding is

necessary, the parameter

values for the passes are

given in the tables without

repeating diameter and

thickness of the tubes.

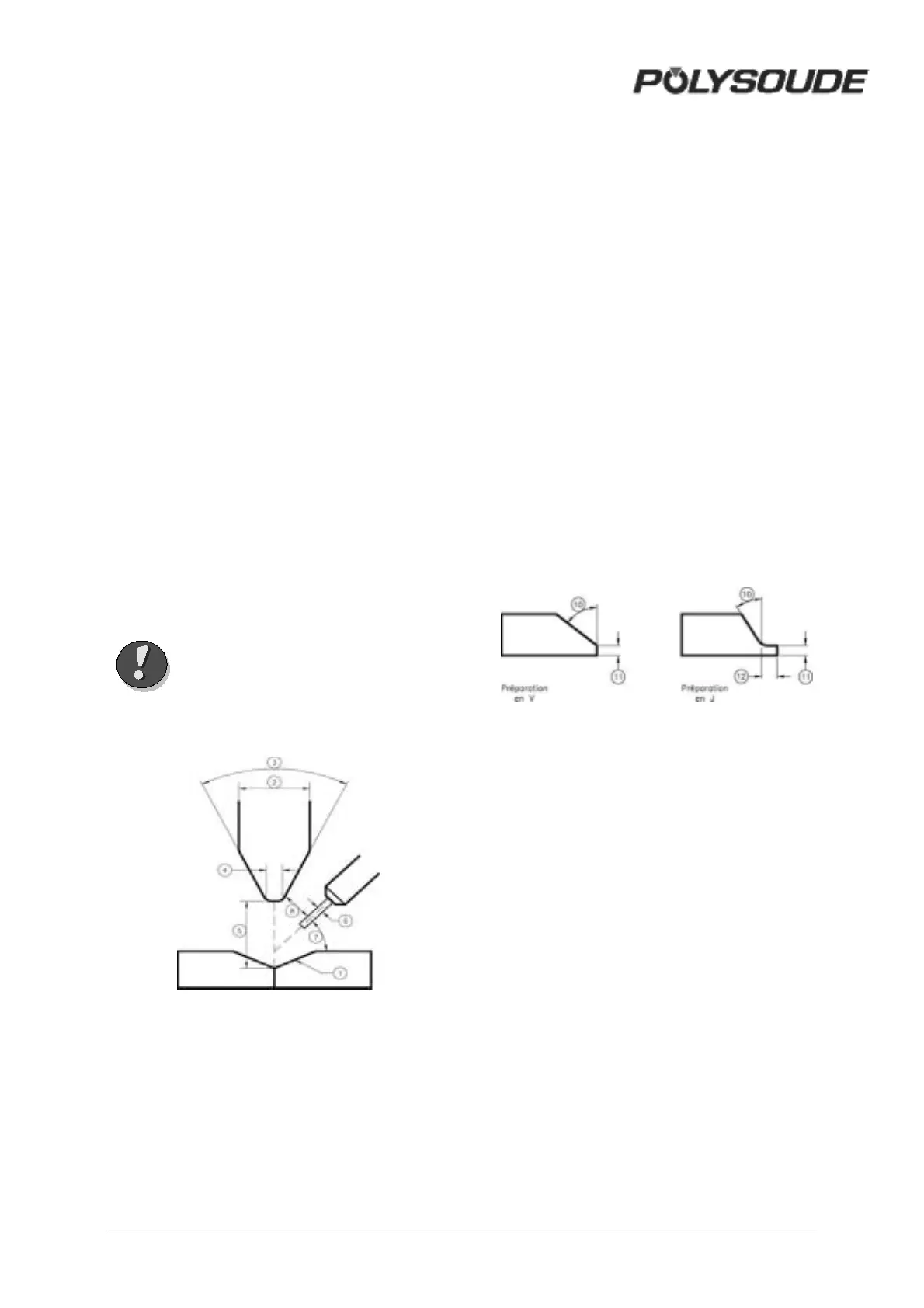

Fig. 5.1 : Weld set-up

If filler wire is used, its diameter is always 0.8

mm.

The set-up of a weld may influence

considerably its result. The set-up is explained

below and, whenever necessary, added to the

programs.

1: Tube end preparation.

2: Electrode diameter.

3: Tip angle.

4: Flat.

5: Distance electrode-workpiece.

6: Diameter of filler wire.

7: Angle between wire and workpiece.

8: Start position of the weld.

9: Start position of the weld.

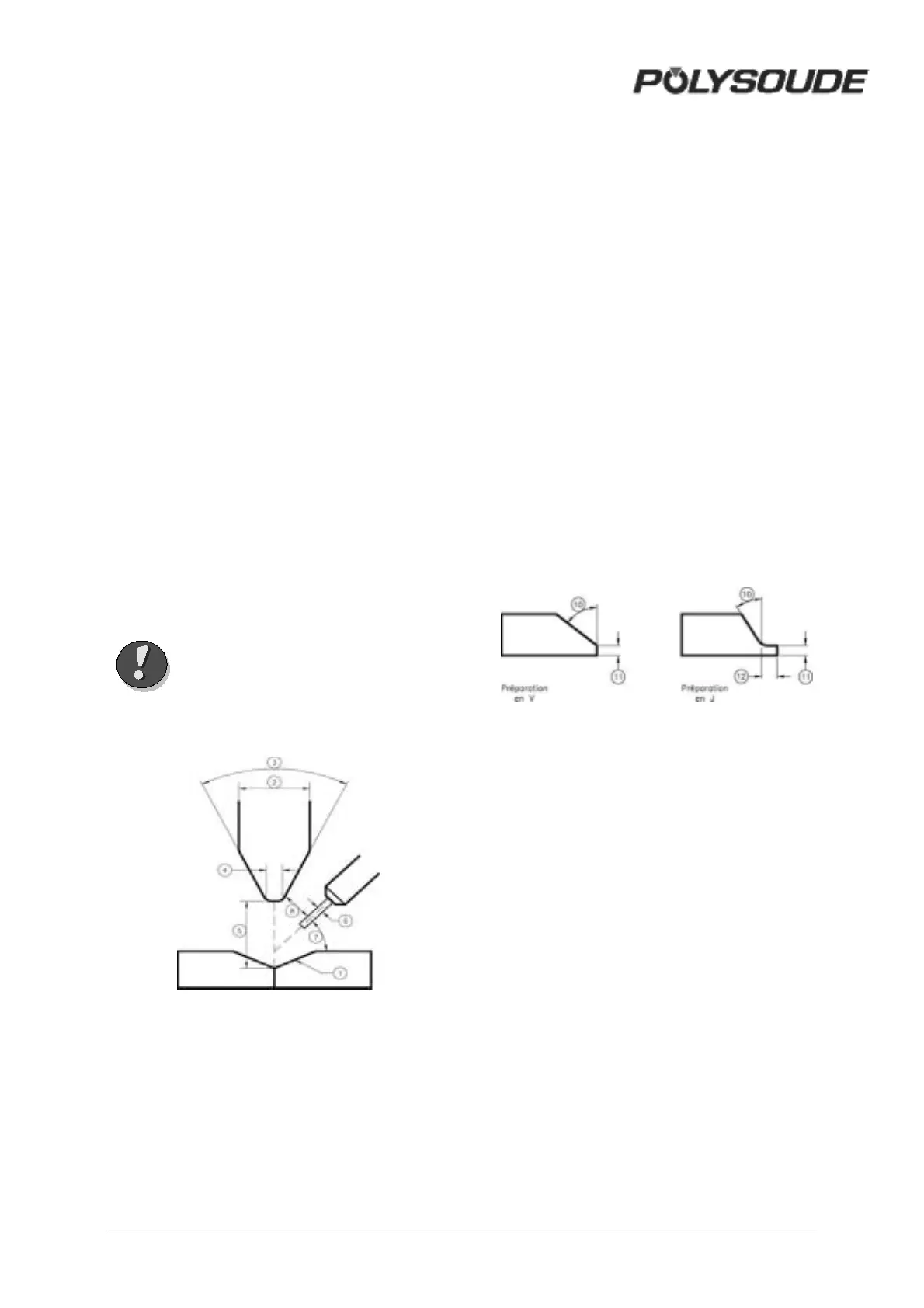

10: Weld preparation angle.

11: Thickness of land.

12: Length of the land (for J

preparation).

Fig. 5.2 : Weld preparation

Loading...

Loading...