80 MAN. PS 254 EN – Ind. 2

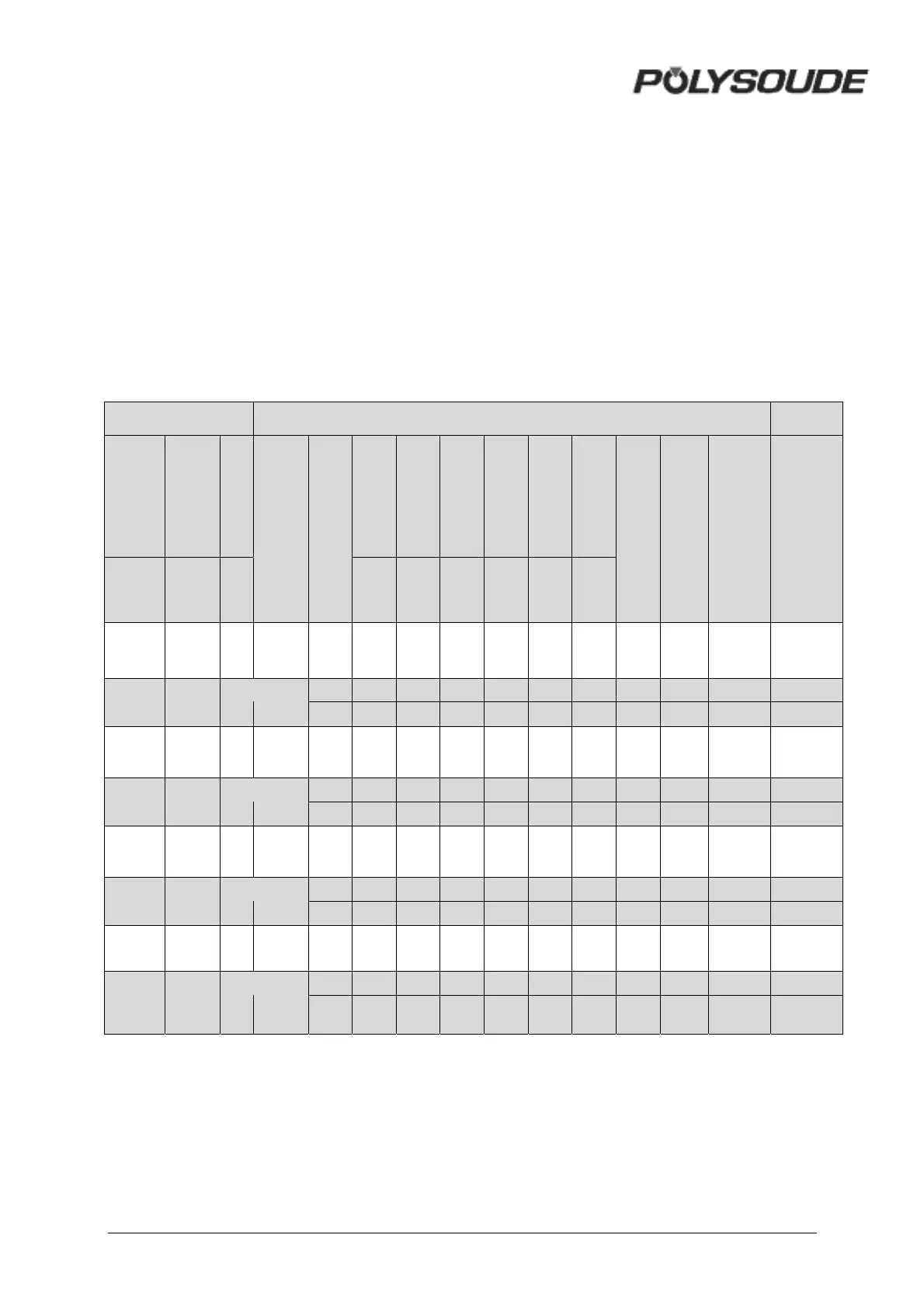

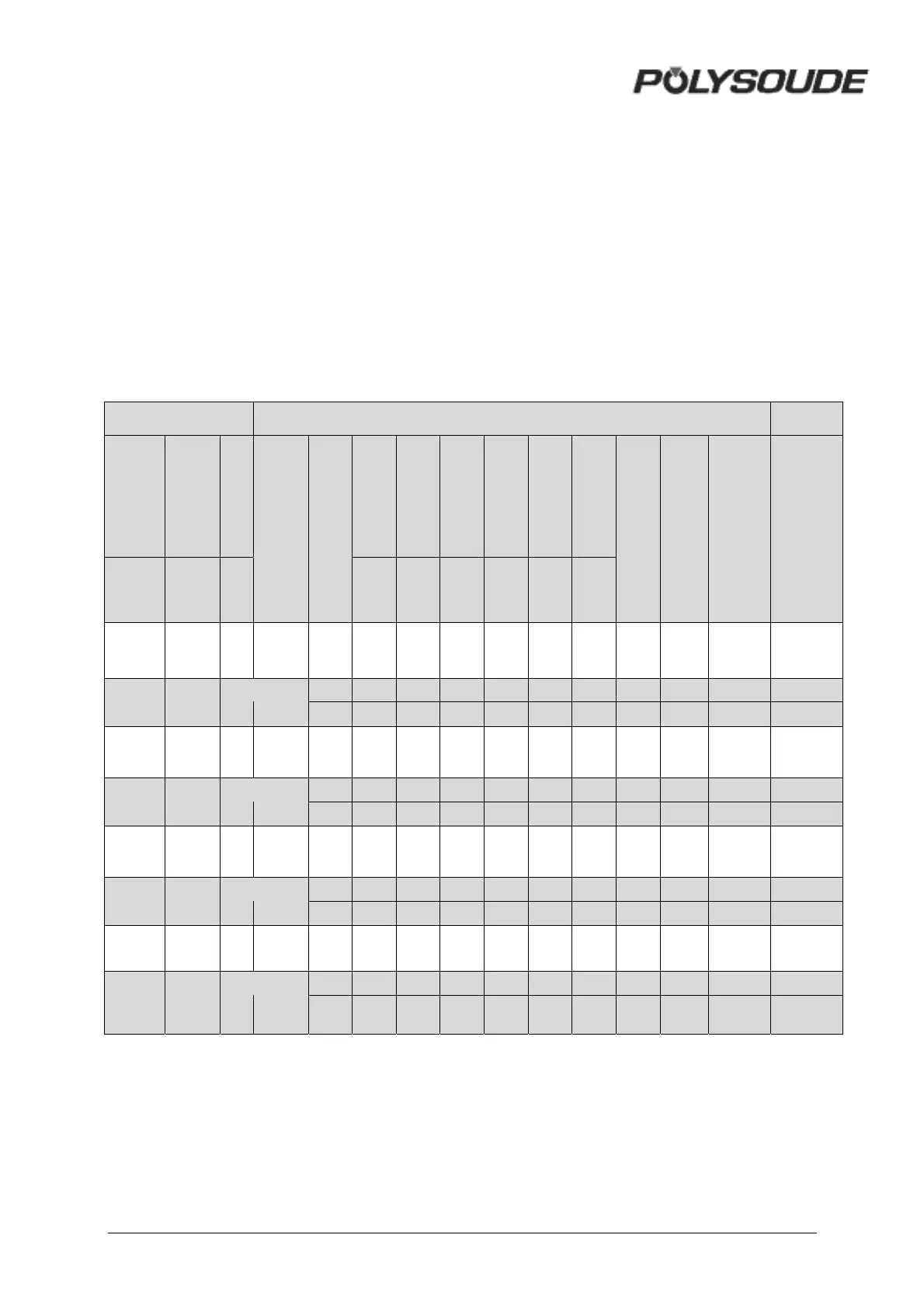

5.1.3. TS/TP welding heads for welding

of tubes to tubesheet

Tube to tubesheet welds may have two

geometrical shapes : flushing or protruding

tubes. For welds of flushing tubes, one pass is

required. For welds of protruding tubes, make

two passes (one with wire and one without

wire). In this case a welding bevel is needed

on the workpiece (angle = 45°,

height: 1.5 mm). For leak resistant welds of

protruding tubes, make one pass (without a

bevel) and then a second pass corresponding

to the tube to be welded.

Tubes to be welded

Set-up before welding Range

Material

Ø OD

Wall thickness

Tube

protruding/flushing

Angle of torch

Distance

électrode/plaque

Distance

electrode/work

piece

Distance

electrode/wire

Ø Electrode

Tip angle

Nose

Ø wire

N° of layer

Built-in program

number

mm

mm

mm

mm

mm

mm

degrees

mm

PS 254

Stainless

25 2

Flushing

0° 2.5 1 2 2.4 30° 0.2 0.8 1/1 81 X

15° 0.5 1.2 2.4 30° 0.2 1/2 83 X

Stainless

25 2

Protruding

15° 2 2 1.2 2.4 30° 0.2 0.8 2/2 84 X

Stainless

26.7 1.5

Flushing

0° 3 1 2.2 2.4 30° 0.2 0.8 1/1 85 X

15° 0.5 1.2 2.4 30° 0.2 1/2 87 X

Stainless

26.7 1.5

Protruding

15° 2 2 1.2 2.4 30° 0.2 0.8 2/2 88 X

Mild

steel

25 2.5

Flushing

30° 2 2 1.2 2.4 30° 0.2 0.8 1/1 90 X

30° 0.5 1.2 0.5 2.4 30° 0.2 1/2 91 X

Mild

steel

25 2.5

Protruding

30° 2 2.2 1.2 2.4 30° 0.2 0.8 2/2 92 X

Mild

steel

25 3

Flushing

0° 2 1 1.2 2.4 30° 0.2 0.8 1/1 93 X

15° 0.5 1.2 2.4 30° 0.2 0.8 1/2 95 X

Mild

steel

25 3

Protruding

15° 2 2 1.2 2.4 30° 0.2 0.8 2/2 96 X

Loading...

Loading...