66 MAN. PS 254 EN – Ind. 2

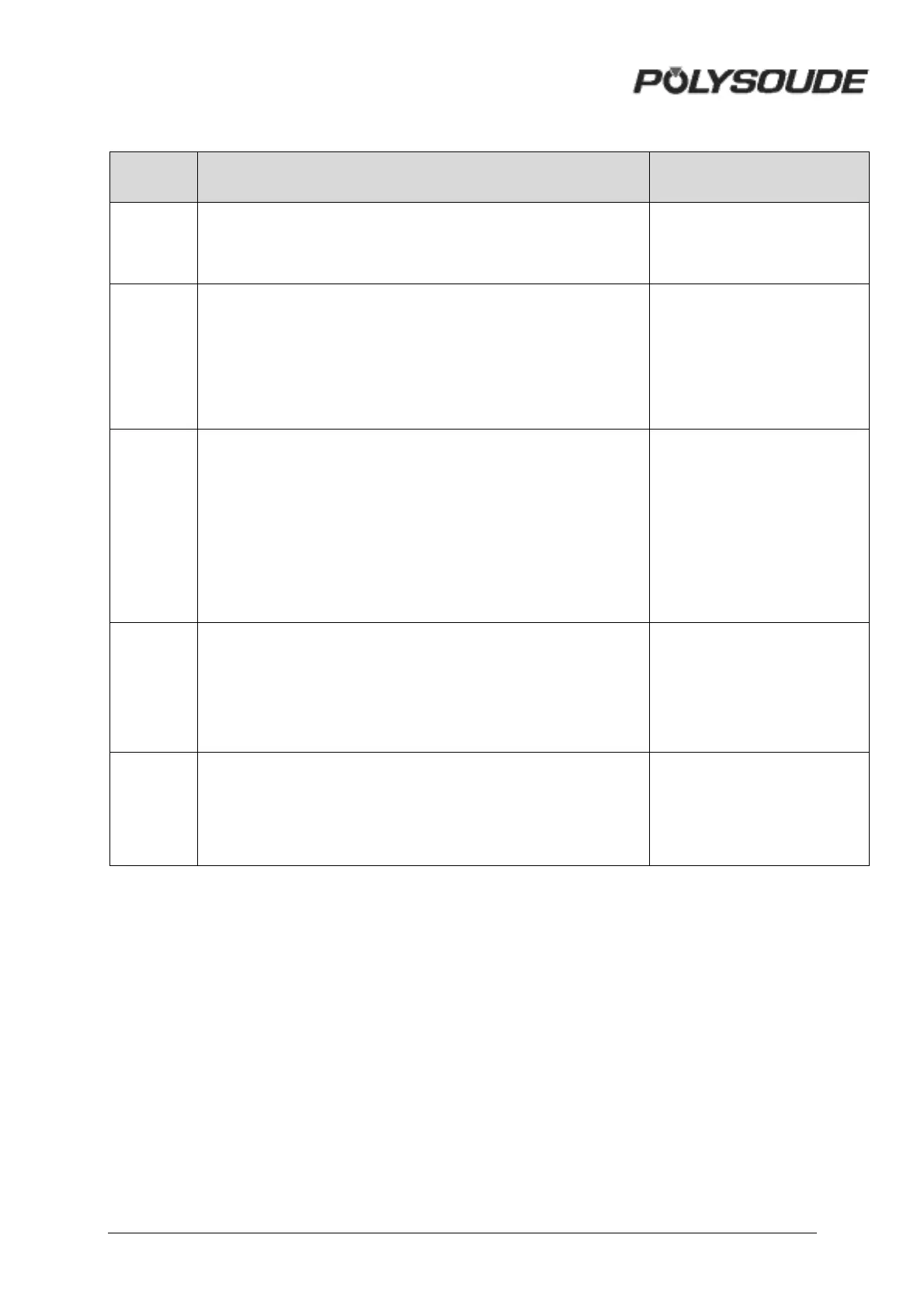

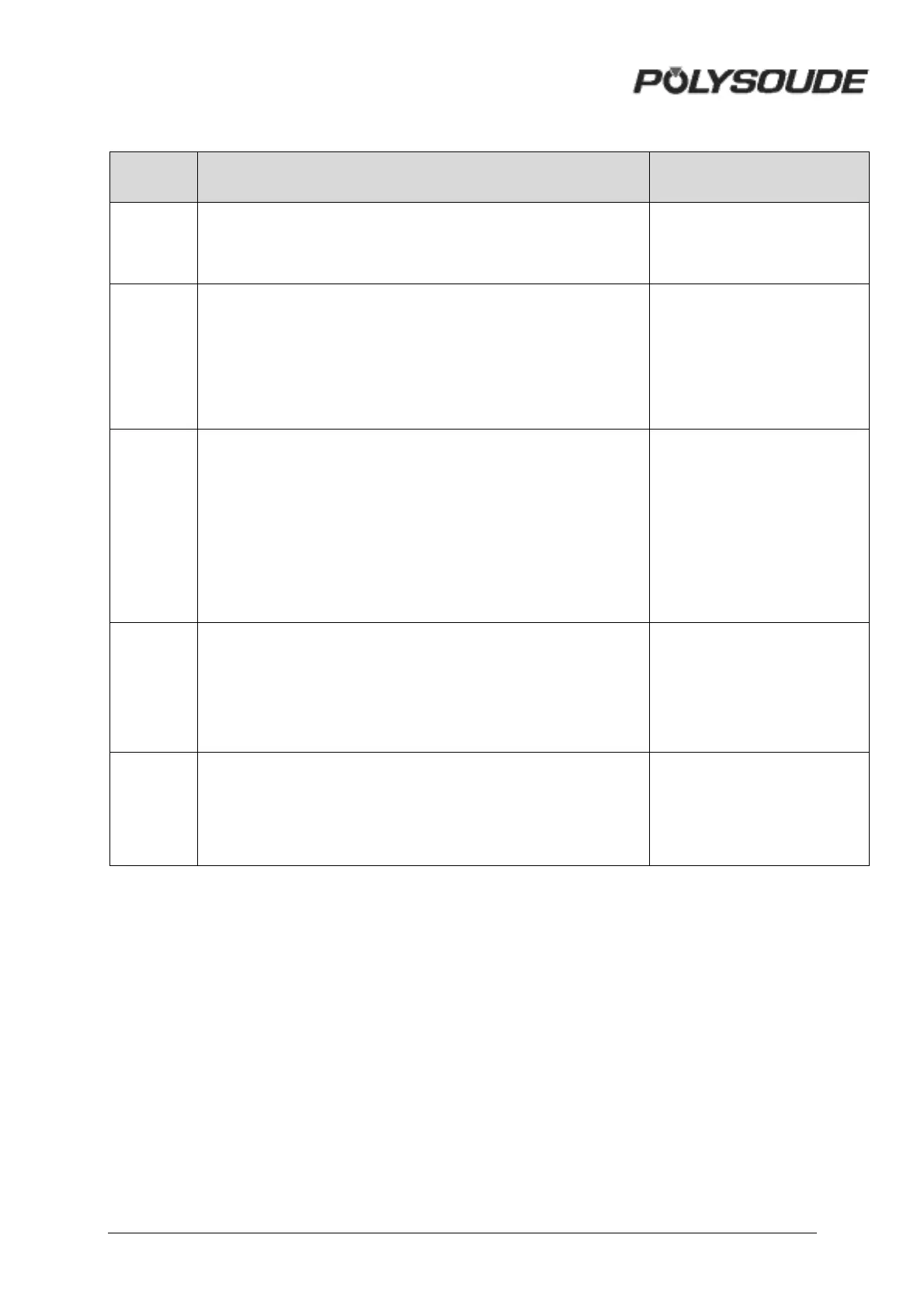

! Display of an error code

Error

code

Possible causes What to do

10

- Shielding gas cylinder empty or valve closed.

- Poor connection of the shielding gas coupling.

- Fuse F 1 on card WK-3 defect.

- Solenoid valve defect.

- Check and change or open.

- Check and connect properly.

- Check and change (§ 4.2.1).

- Can be checked only by a

qualified specialist.

11 or 12

- Level of cooling liquid low.

- Hoses of the cooling circuit buckled or knotted, filter clogge.

- Fuse F 2 on card WK-3 defect.

- Shunt for cooling circuit security not mounted (use of air cooled

welding heads only).

- Quick gas coupling of the welding head not fastened.

- Pump defect.

- Hose bundle defect (welding heads MU).

- Check and correct.

- Keep in proper conditions.

- Check and change (§ 4.2.1).

- Refer to §2.3.3 to make

connections properly.

- Check and connect properly.

- Can be checked only by a

qualified specialist.

- Change.

22

- Weld current cable poorly connected or interrupted.

- Bad position of the ground cable.

- Wrong gas flow adjustment.

- Electrode polluted or distance workpiece / electrode too high.

- Hose bundle defect (welding head MU).

- Ignition aid defect or in wrong position (welding heads MU, TP, TS...).

- Wrong shielding gas (He).

- Power source poorly adjusted.

- Check and change.

- Deplace ground cable (refer to§

3.2.3 or 2.3.7).

- Check.

- For correct electrode settings,

refer to operating manual of the

welding head.

- Change.

- Position ignition aid correctly.

- Try argon.

- Can be checked only by a

qualified specialist.

23

- Electrode tip poorly ground or worn out.

- Distance workpiece / elektrode wrong.

- Poor shielding gas protection.

- Programmed weld current too low, when the arc starts.

- Ignition aid defect or in wrong position (welding MU, TP, TS...).

- Refer to operating manual of

the weld head for correct set up

and change of the electrode.

- Correct.

- Check gas flow, clean or

change gas lens.

- Correct.

- Change or correct position.

24

- Electrode has touched the workpiece.

- Electrode has touched the filler wire.

- Ignition aid defect or in wrong position (welding MU, TP, TS...).

- Lack of insulation between welding head and wire guide support.

- Card 217 00 633 defect.

- Inverter unit defect (card TRDC2).

- Correct

- Change the position of the wire

inlet move

- Move

- Check and correct

- Replace

- Call After Sales Service

Loading...

Loading...