PreciseFlex_Robot

102

5. The tension is set to the value in Appendix E by adjusting the M5 set screw which pushes on a

spring in the Z Axis Idler Plate. Re-tighten the 3 screws and replace the Front Cover and Top

Plate. (Alternate Method: For the 750mm and 1160mm Z travel robots, it can sometimes be

difficult to get a good tension reading for the spans for these long belts, which are 880mm and

1290mm respectively and as a result have low vibration frequencies. In this case it may be

easier to position the Z carriage so that the span from the top idler pulley to the Z carriage is

530mm, which is the span for the 400mm Z stroke when measured on the left hand side of the

belt as shown above. With the carriage at this location with a span of 530mm, for these longer

travel Z strokes, you can then measure the tension on the right hand side of the belt, and use the

values for tension and frequency for the 400mm Z stroke.)

Tensioning the J2 Belt

DANGER: Before tensioning the timing belts the AC power should be disconnected.

Removing the front cover allows access to the AC power terminals.

Tools Required:

1. Gates Sonic Belt Tension Meter, Model 507C

2. 3.0mm hex driver or hex L wrench

3. 2.5mm hex driver or hex L wrench

4. 2.0mm hex ball driver or hex L wrench

In order to re-tension the J2 (shoulder) Timing Belt, the user must:

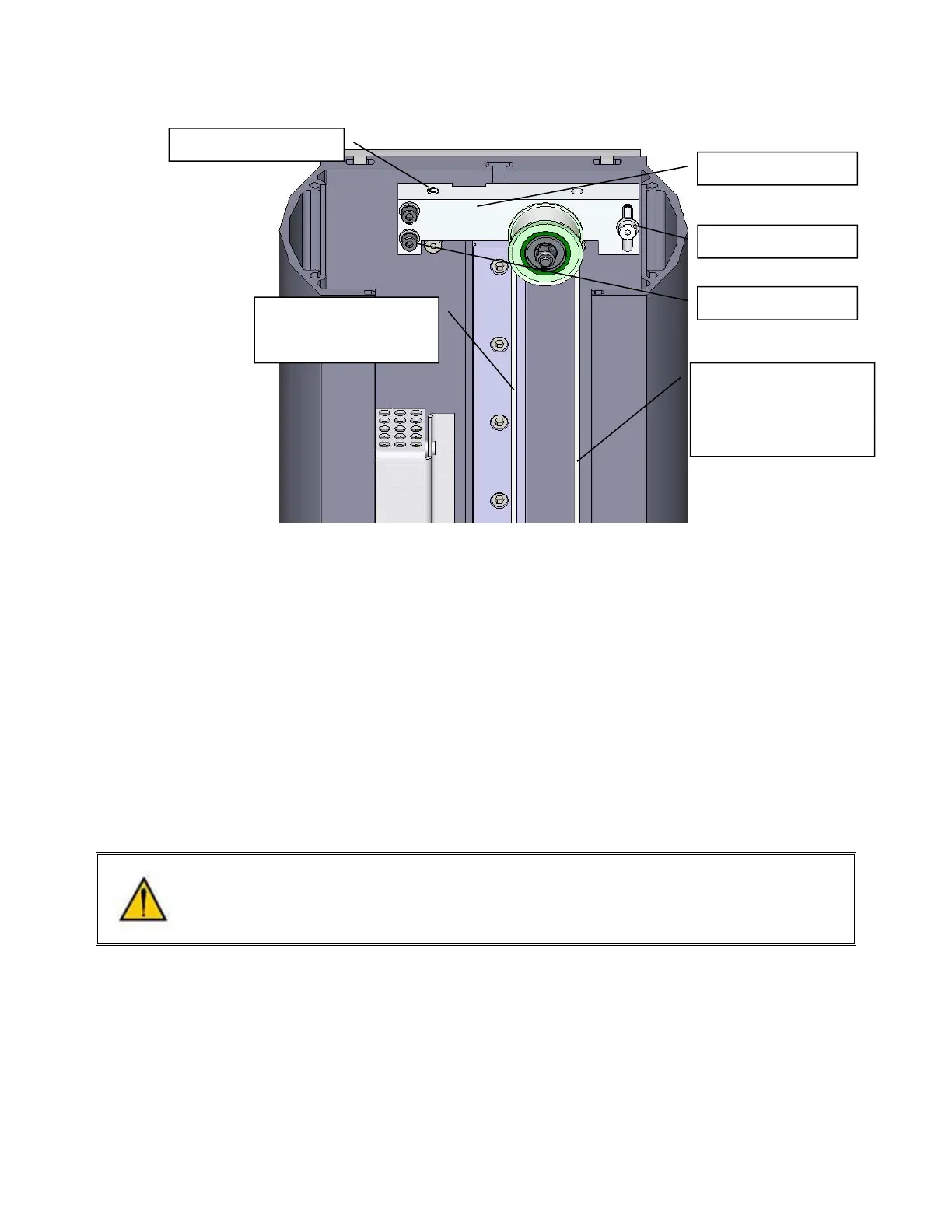

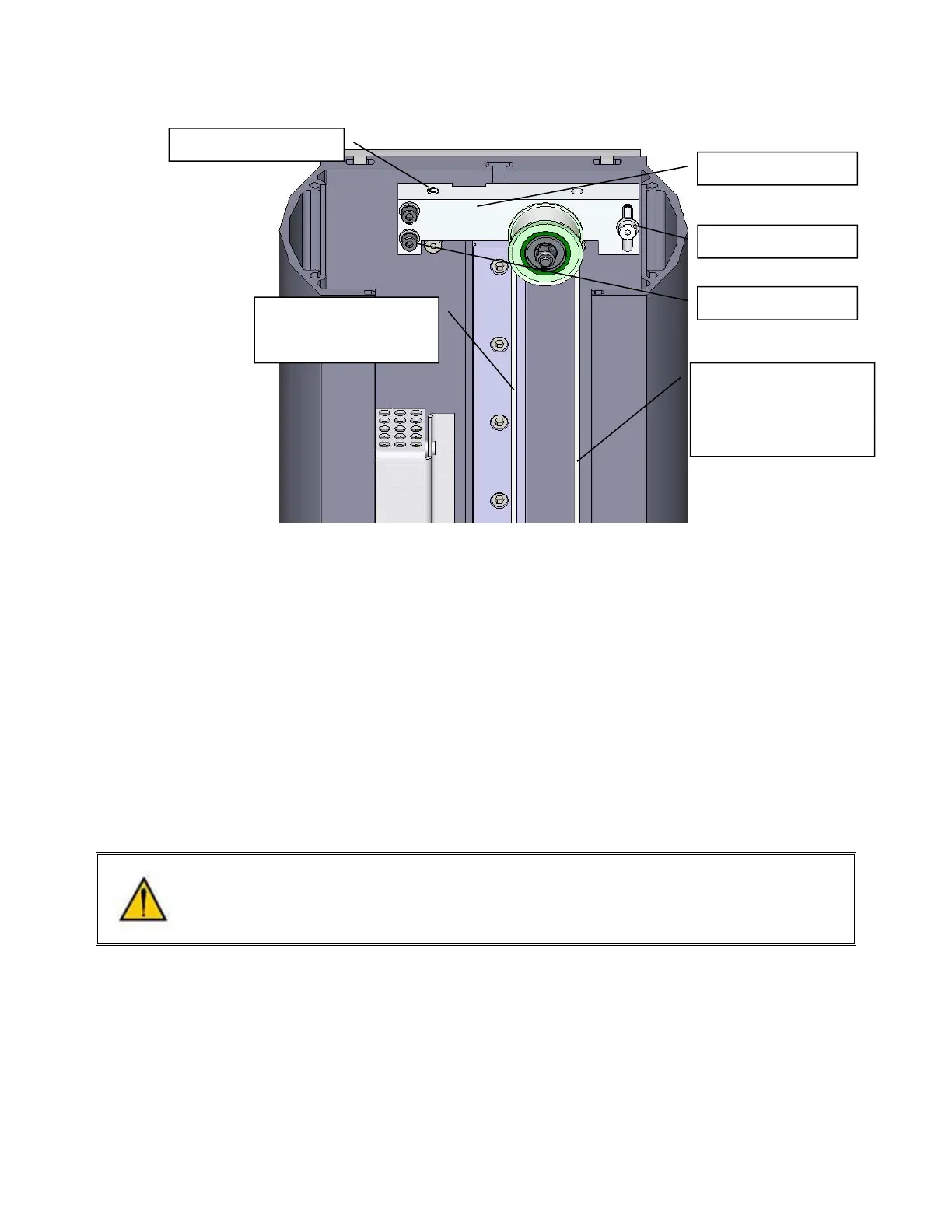

Z Axis Idler Plate

M5 Shoulder Screw

M4 Locking Screws

Measure this side so

that the span is

correct.

Tension Adjust Screw

Measure this side only

if using Alternate

Method for long Z

strokes.

Loading...

Loading...