PreciseFlex_Robot

18

Controller Requirements

Early industrial robots were often large, powerful machines with payloads that could exceed 100kg. As a

result, the industrial robot safety standards such as ISO 10218-1 often specified a Category 3 control

system for these machines, see ISO 10218-1:2011 5.4.2 and 10218-2:2011 5.2.2. However, these

standards now recognize that not all robots are large, dangerous machines and include clauses that allow

less expensive controllers to be used if a risk assessment justifies this. 10218-1:2011 5.4.3 states “The

results of a comprehensive risk assessment performed on the robot and its intended application may

determine that a safety-related control system performance other than that in 5.4.2 is warranted for the

application”. 10218-2:2011 5.2.3 makes a similar statement. Note that in performing a risk assessment

under ISO 13849, the first determination, S1 or S2, is made based on whether an operator may sustain a

serious or non-recoverable injury. For large, heavy payload robots, S2 is typically selected and this

immediately directs the evaluation result to a PLr of c, d, or e, which indicate a Cat 3 controller. For low

payload robots, S1 is typically selected which directs the evaluation to a PLr of a, b, or c. In Appendix A

of this section an example risk assessment is provided for a PF400 robot with a 500 gram payload and

the PL is determined to be “a”. This does not require a Cat 3 controller or robot system.

Possible Precise Controller Faults and Controller Testing

Notwithstanding the above, Precise controllers are designed so that no single failure can disable the

safety features in the controller and cause an uncontrolled motion. However, the 500gm payload PF400

robots are not Category 3 robots as they cannot cause serious injury and the expense and complexity of

100% redundant safety systems is not warranted. For the 3kg payload version of the PF400 an additional

circuit board has been added in the base of the robot. This circuit board provides redundant, PLd CAT 3

Estop and other safety circuits.

Safety circuits, Failure Modes, and TUV Testing for the PF400 robots. (Appendix D)

1. Force Limits by Design or Control. The PF400 is a low power robot by inherent design and

control. For axes 2, 3, 4, and the gripper, the maximum forces that can be applied by the motors,

multiplied by the transmission are well under 140N. In the case of the Z axis, the maximum force

required to support the Z axis gravity load of up to 80N plus a reasonable additional force for

acceleration against gravity of 60N, results in a total force of 140N, and is restricted by current

limits in firmware. A further reduction in force is set by collaborative force limits in software, so

that the clamping/squeezing force (quasi-static) does not exceed 60N.

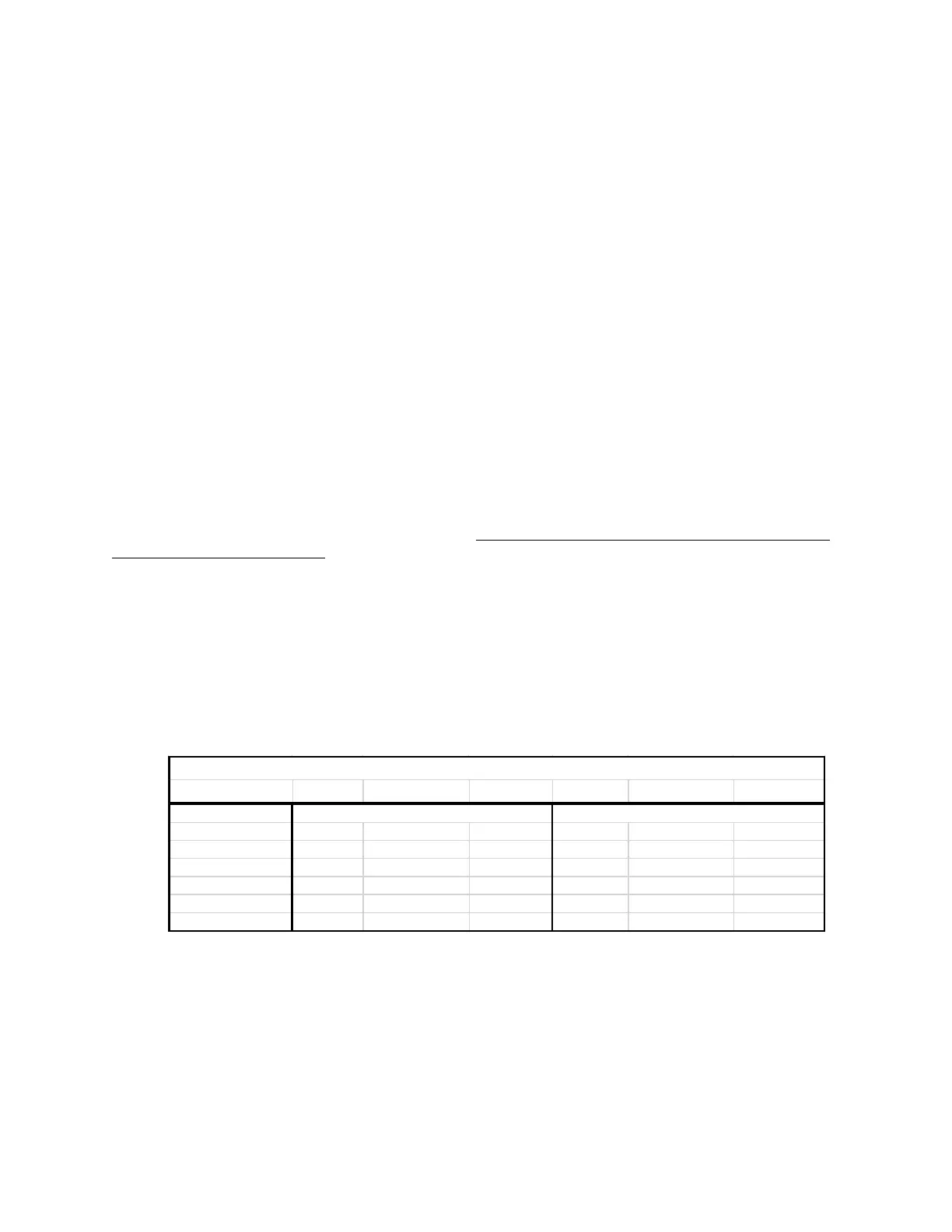

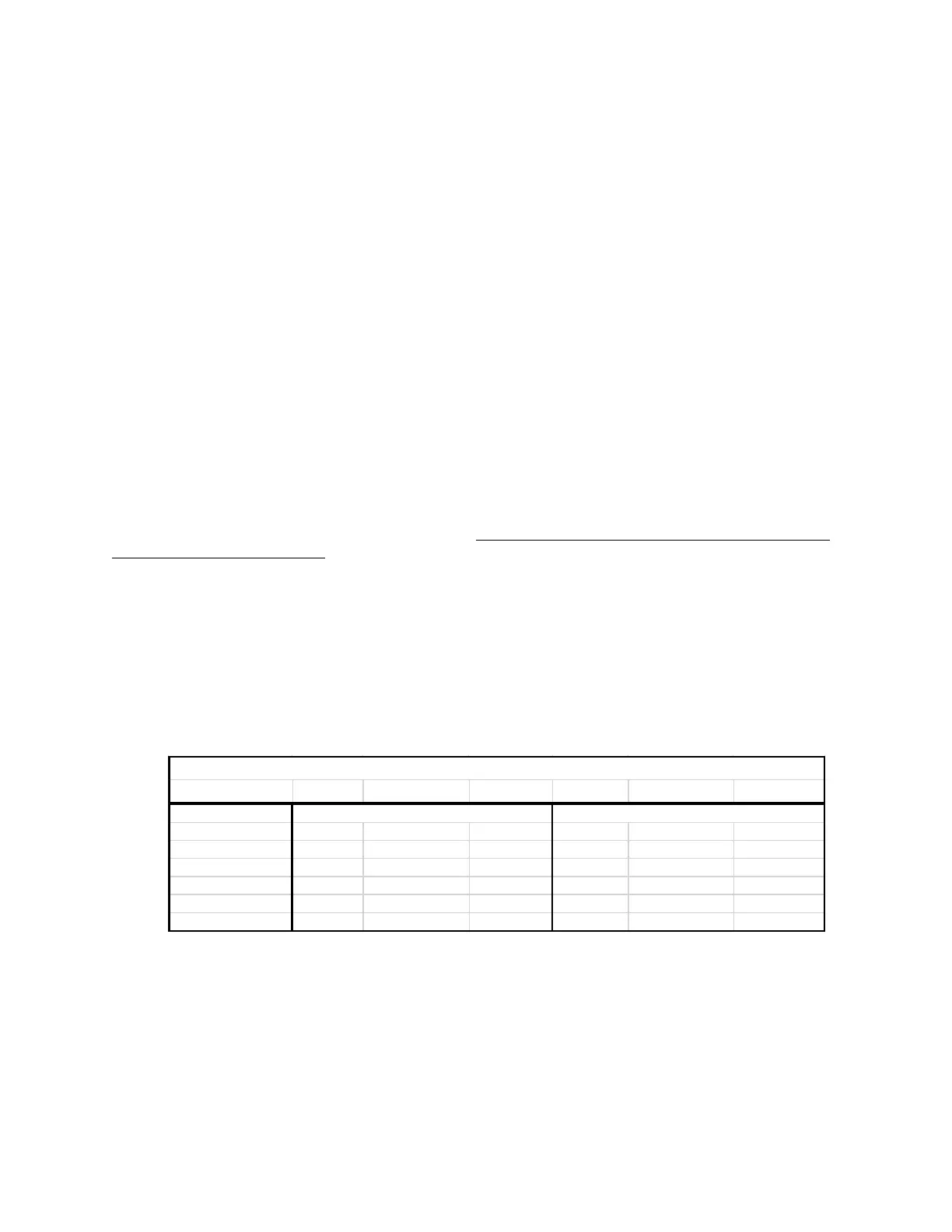

Unlimited CurrentLimited Collablimit Unlimited CurrentLimited Collablimit

Zaxis 314 140 60 314 140 60

J2atelbow 33 33 33 64 64 18

J3atwri st 18 18 18 25 25 9

J4atgripper 11 11 11 17 17 9

Gri ppersqueeze 23 23 23 23 23 23

PF4003kgPF400500gm

PF400MaximumForces,Newton

2. Estop circuit for 500gm payload PF400. For the 500gm payload PF400 plate handler, there is

a single Estop circuit. However, the forces applied by this machine are so low (less than 60N at

low speeds – see TUV test certification) that most users simply use their hand to stop the plate

handler and do not employ an Estop button or pendant. If the Estop circuit is interrupted the

robot will decelerate and stop in a Category 1 Estop (decelerate using motor power then turn off

motor power). The Estop circuit for the 500gm plate handler is not CAT 3 in that there are not

two redundant external Estop circuits. However, a redundant Estop method is available for this

low power robot: users can very easily stop it with their hand by grabbing the gripper or links. For

TUV testing the forces required to stop the robot and trigger an Estop are measured with a NIST

Loading...

Loading...