PreciseFlex_Robot

14

5.10.5 Power and force limiting by inherent design or control

“The power or force limiting function of the robot shall be in compliance with 5.4. If any parameter limit is

exceeded, a protective stop shall be issued.”

Section 5.4 requires the system designer to perform a Performance Level (PL) or Safety Integrity Level

requirement (SIL) check based on the robot AND the application tooling and workcell. For example, a

safe robot may still need safety interlock screening if it is moving a dangerous tool. This requires the

application designer to review the requirements of 10218-2:2011 which addresses robots in workcells.

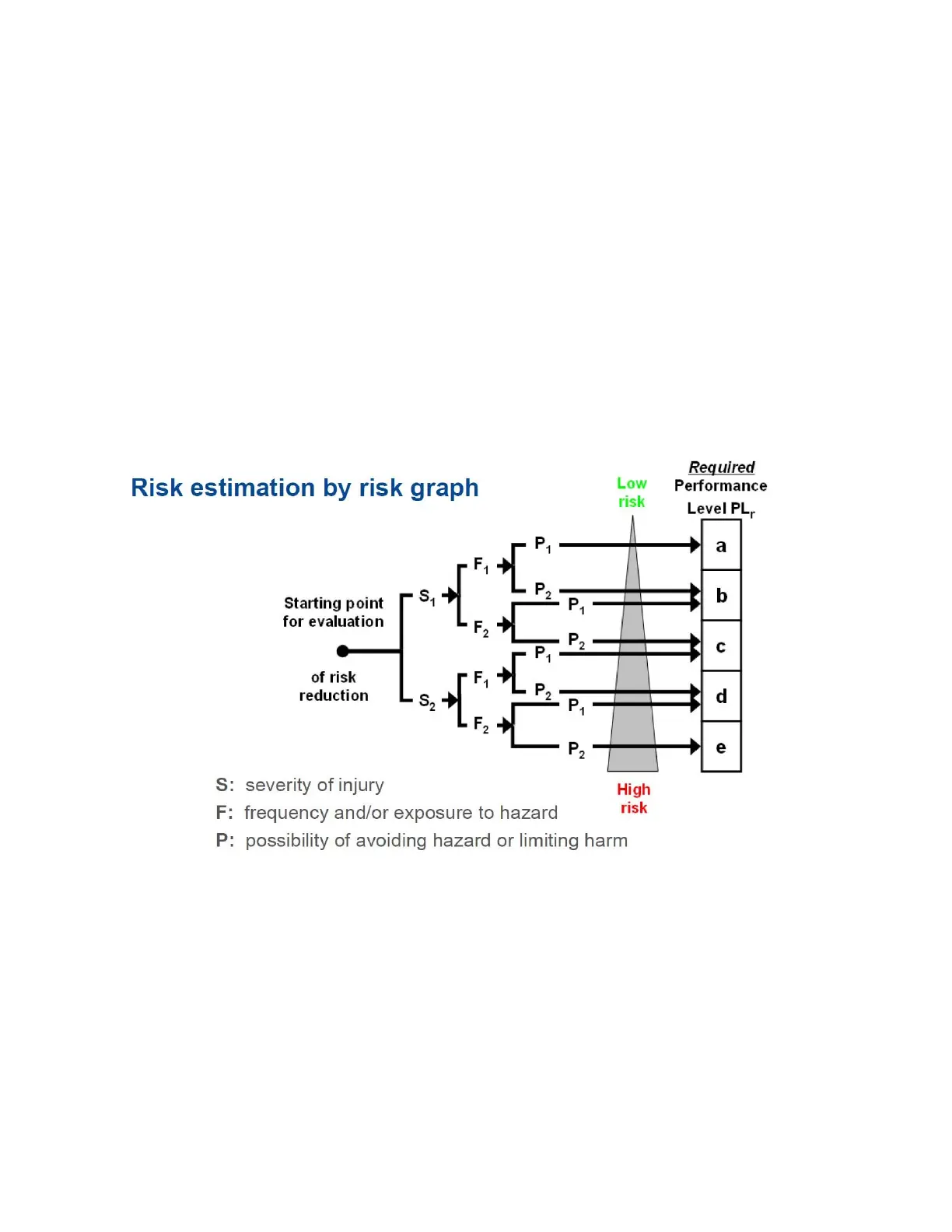

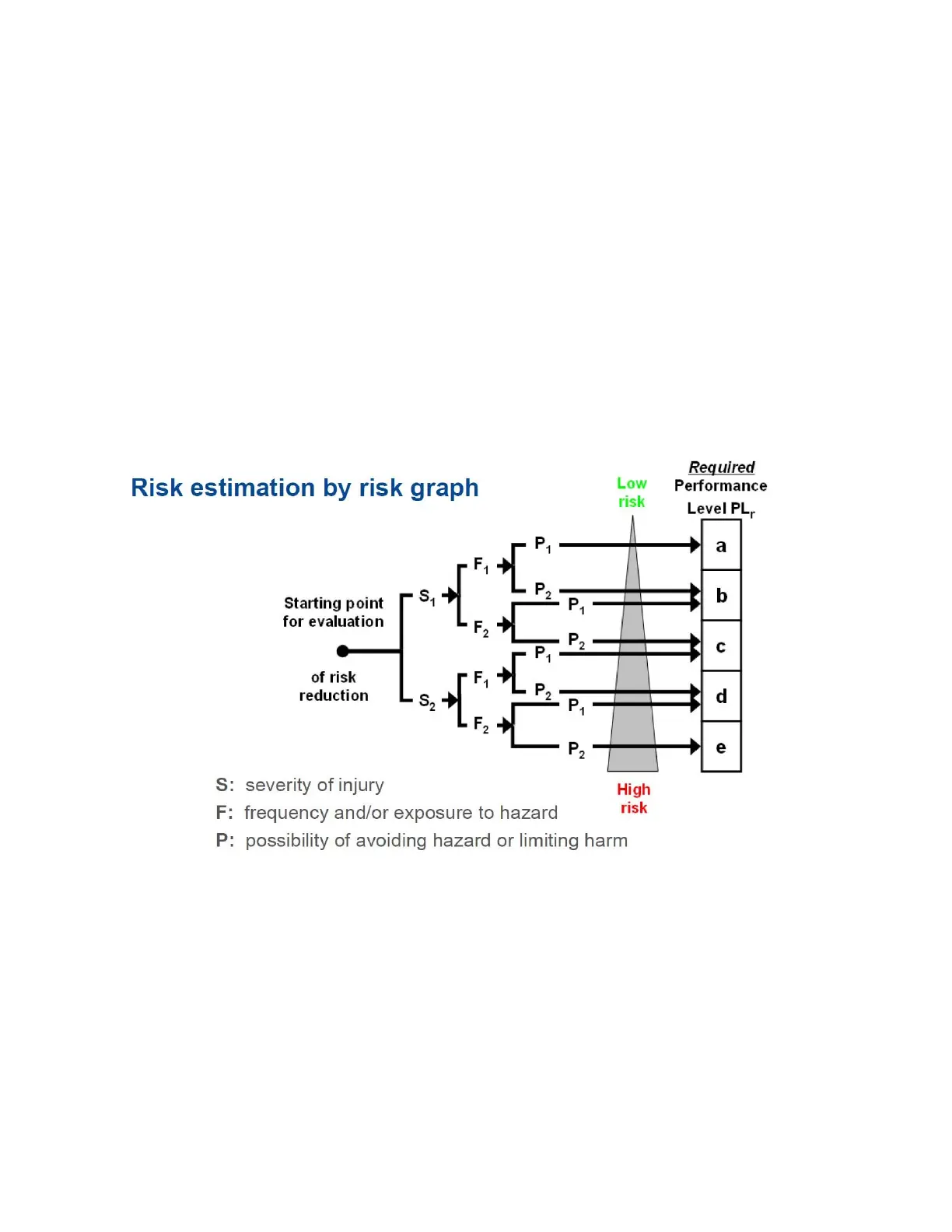

Determining a Machine’s Required Performance Level (PLr). ISO 13849-1:2006 Annex A provides

tables and a worksheet to identify a machine’s Required Performance Level requirements. Figure 1 below

shows a flow chart for determining Performance Levels. Briefly these are: Select S1 for slight injuries

(normally reversible) and S2 for serious injuries or death. Select F1 for infrequent exposure to a hazard

(for example only from time to time) and F2 for frequent exposure (for example continuously entering

workcell). Select P1 for easily recognizing and avoiding a hazard (for example a repetitive motion) and

P2 for a hazard that may be difficult to avoid (for example a sudden, non-repetitive motion that may trap

an operator). An example of determining PL for a PF400 workcell is given in Appendix A of this section,

where it is shown that a PL of “a” is sufficient for the workcell.

Figure 1

In determining whether operators should be prevented from entering a workcell while a robot is moving,

the first question that must be answered when performing a risk assessment is determining the likely

severity of injury if a robot strikes a person. If the robot will not injure a person in the event of a collision,

and there is no other equipment in the workcell that can injure a person, then a person may be allowed to

enter the workcell while the robot is moving.

Loading...

Loading...