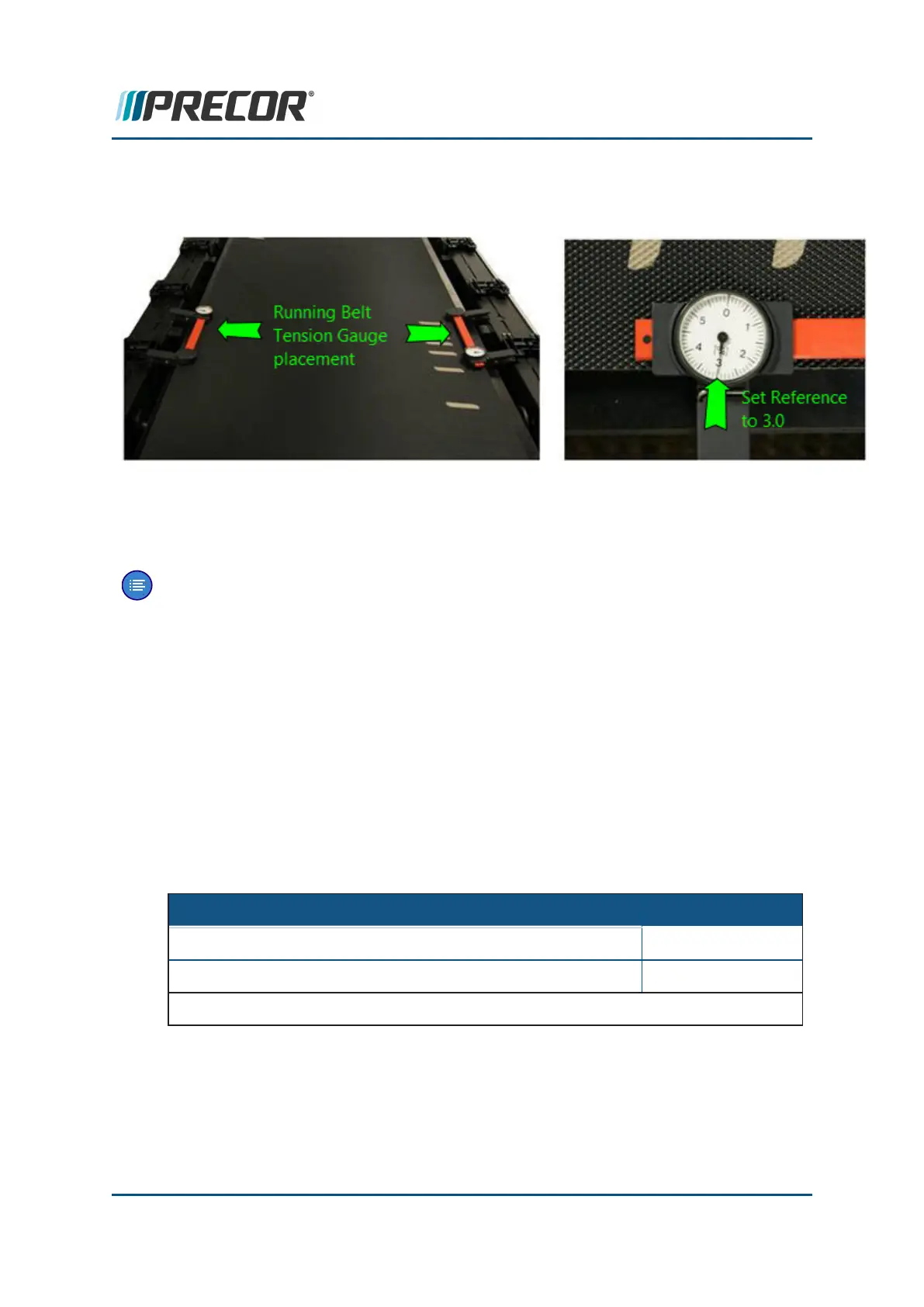

8. Attach a running belt tension gauge on each side of the running belt opposite each

other. Place the gauges so that the trim landing mounting brackets do not interfere with

the gauge movement.

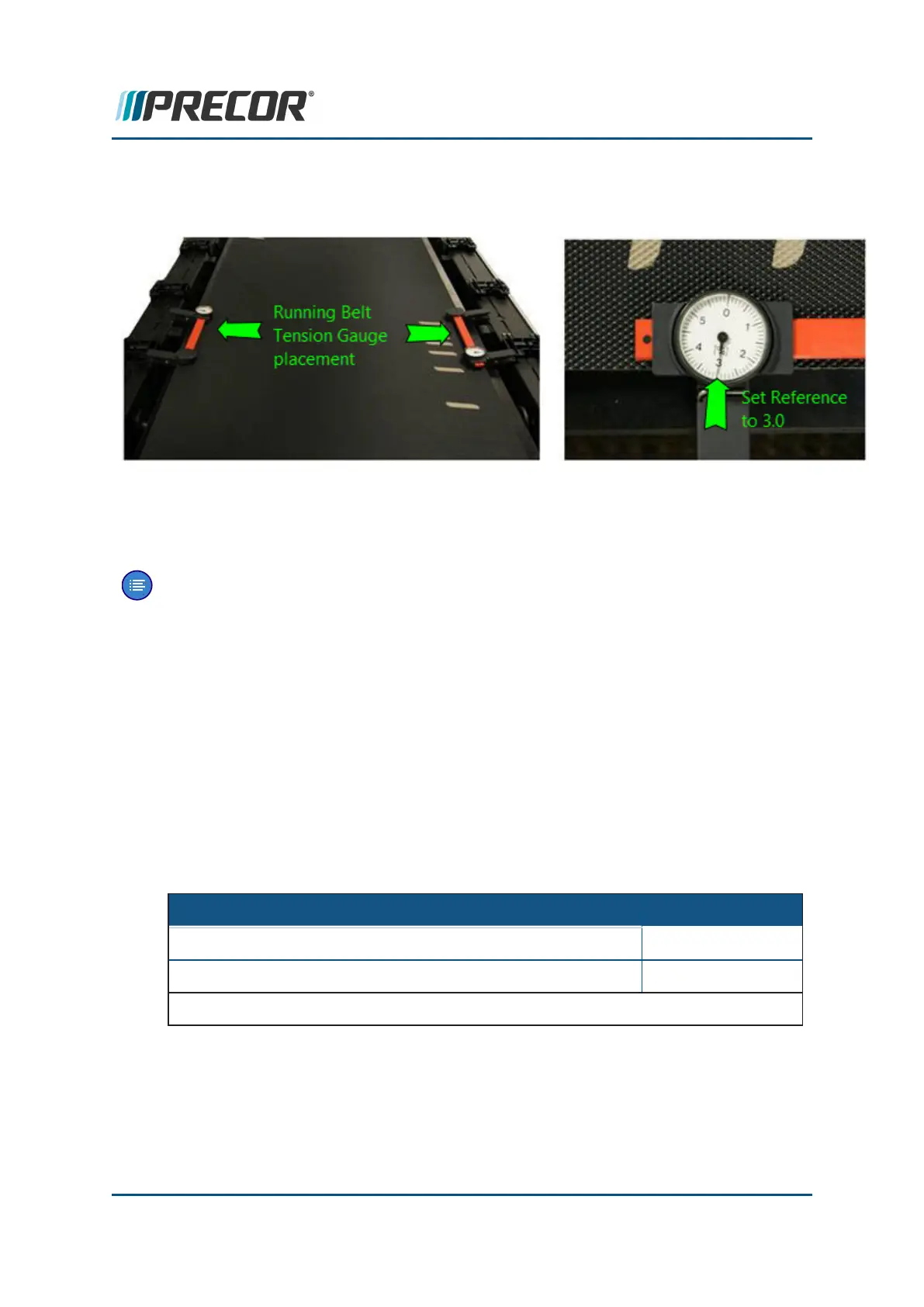

9. Slide the gauge head to set the dial needle as close as possible to 3.0 (0.0%) and clip

the gauge onto the belt edge. Then rotate the gauge dial face to fine adjust the needle to

precisely 3.0 (0.0%)

Note:Setting the gauge to a 3.0 reference value centers the gauge head travel allow-

ing +/- movement without impeding travel.

10. Alternately tighten the right and left running belt tension adjustment bolts in increments

of 0.2 (0.2%) dial divisions so that the belt is evenly tensioned to the manufacturer spe-

cification:

a. Incrementally and alternately tighten the left and right adjustment bolts entail

each gauge dial reaches a value of 3.0.

b. Tighten the right adjustment bolt to dial setting 3.1, then the left adjustment bolt to

3.2.

c. Tighten the right adjustment bolt to dial setting 3.3, then the left adjustment bolt to

3.4.

d. Finish tightening the right and left adjustment bolts to OEM spec: Forbo belt 3.55

(0.55%) or Ammeraal belts 3.75 (0.75%).

Running Belt Brand Specification

ammeraal brand running belt tension (gauge/percent) 3.75 (0.75%)*

Forbo brand running belt tension (gauge/percent) 3.55 (0.55%)*

Notes:*Referenced to gauge reading 3.0 (0.0%)

Contact Precor Customer Support at support@precor.com or 800.786.8404 with

any questions.

Page 58

5 Adjustment Procedures

Running Belt Tension and Tracking Adjustment

Loading...

Loading...