54 516514

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

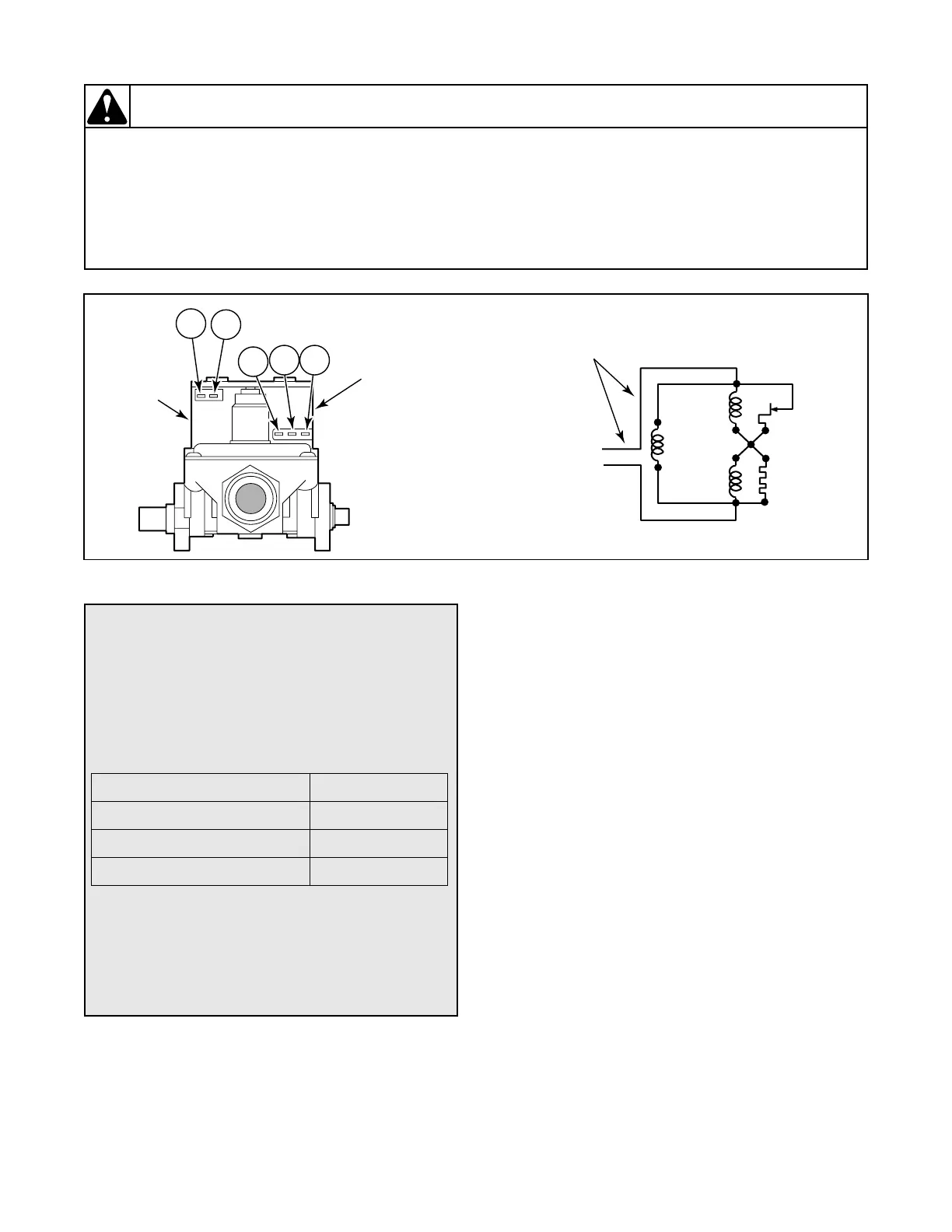

Figure 40

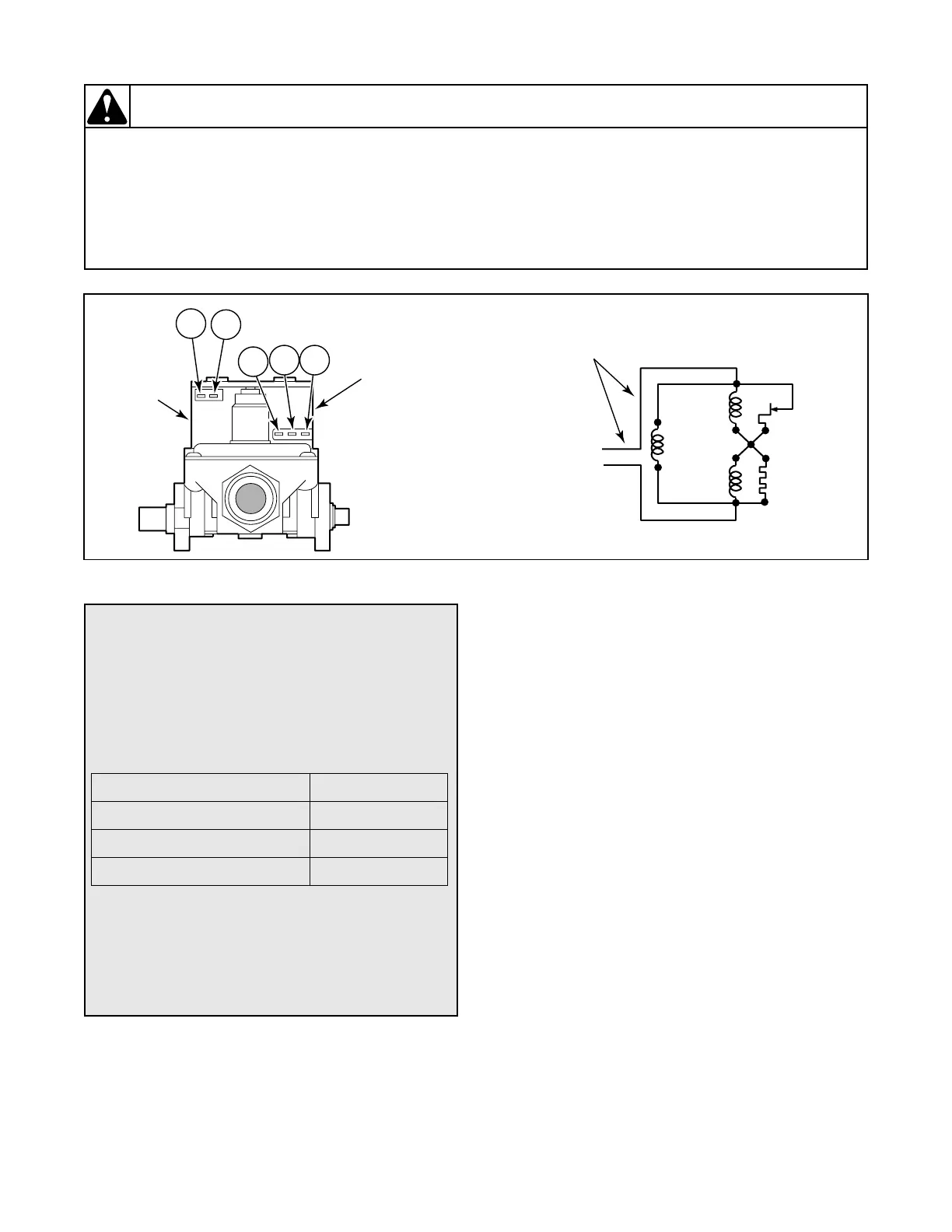

SECONDARY

COIL

HOLDING COIL

AND

BOOSTER COIL

(SPLIT COIL VALVE)

4

1

5

2 3

D267SE3B

SENSOR

SECONDARY

COIL

HOLDING

COIL

BOOSTER

COIL

IGNITER

120 VOLT, 60 HERTZ

ELECTRICAL

SUPPLY LINE

D268SE3A

To Test Gas Valve Coils

(Gas Models)

1. Remove disconnect blocks from gas valve coils.

2. Set test meter to read Ohms and put meter

probes to terminals shown in Figure 40,andin

the following chart.

SILICON CARBIDE IGNITION:

Coil Tolerance Readings

SILICON NITRIDE IGNITION: Both coils should

read between 2400 - 2800 Ohms.

NOTE: If meter registers any other readings than

those listed above, the respective coil(s) should be

replaced.

Meter probes to terminals: Meter should read:

Holding Coil – Terminals 1 & 2 1365 ± 25 Ohms

Booster Coil – Terminals 1 & 3 560 ± 25 Ohms

Secondary Coil – Terminals 4 & 5 1220 ± 50 Ohms

Loading...

Loading...