Section VIII - Technical data

Electric cable size and fuses

Important

NOTICE!

The voltage on the vacuum pump terminals must not deviate more than 10% of the

nominal voltage.

It is however highly recommended to keep the voltage drop over the supply cables

at nominal current below 5% of the nominal voltage (IEC 60204-1).

•Ifcablesaregroupedtogetherwithotherpowercables,itmaybenecessarytouse

cables of a larger size than those calculated for the standard operating conditions.

•Usetheoriginalcableentry.SeesectionDimensiondrawings.TopreservetheIP

protection degree of the electric cubicle and to protect its components from dust

from the environment, it is mandatory to use a proper cable gland when connecting

the supply cable to the Vacuum pump.

•Localregulationsremainapplicableiftheyarestricterthanthevaluesproposedbelow.

Caution:

•Alwaysdouble-checkthefusesizeversusthecalculatedcablesize.Ifrequired,reduce

fuse size or enlarge cable size.

•CablelengthshouldnotexceedthemaximumlengthaccordingtoIEC60204table10

Leakage breaker (optional)

If the installation requires a leakage breaker, always use an all current sensitive leakage

breaker, RCM or RCD Type B (according to IEC/EN 60755) with a sufcient trip level.

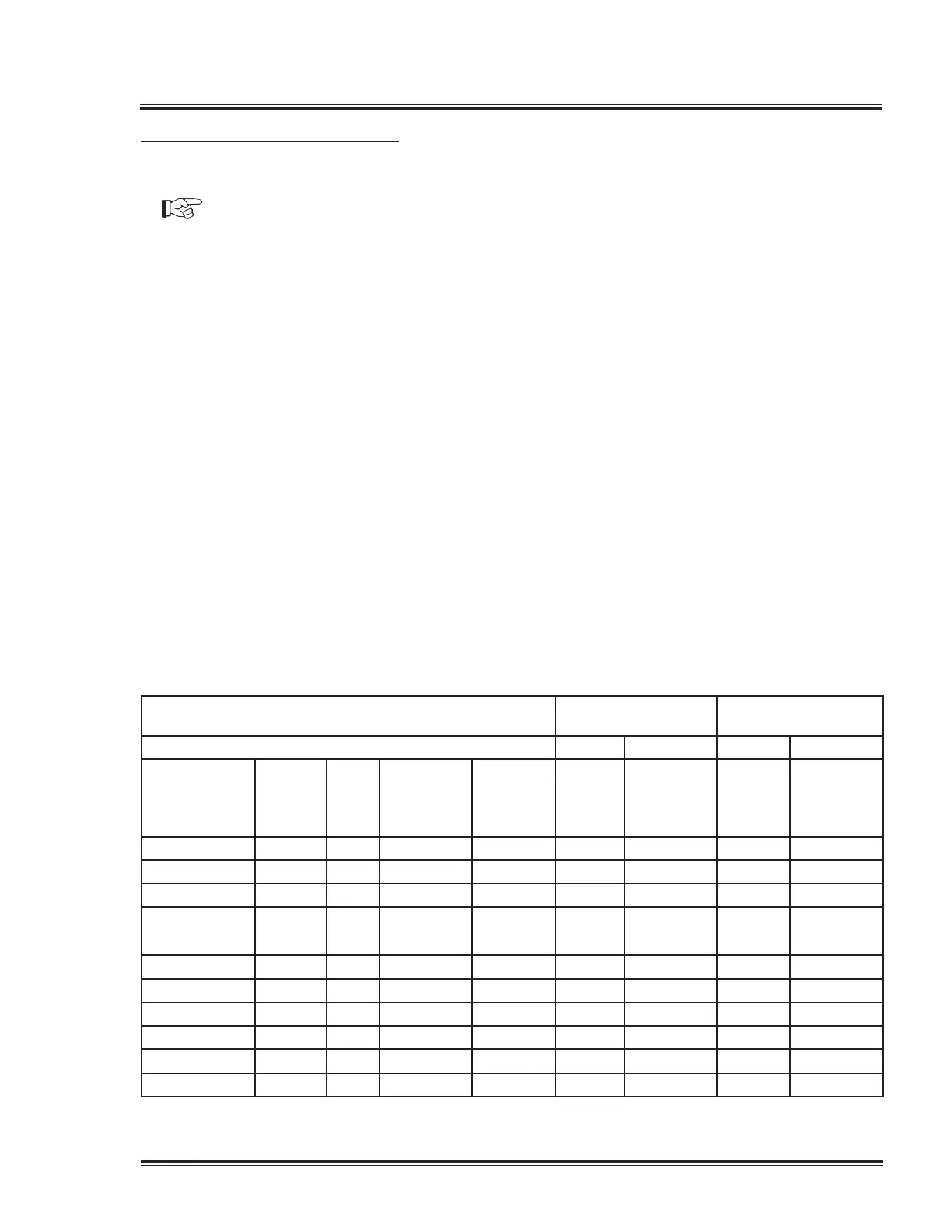

Currents and fuses

IEC and UL/cUL approval

Vacuum pump specication Itot Imax undervoltage

Primary Secondary Primary Secondary

Pump Voltage Freq.

Secondary

voltage

autotran-

sformer

Approval

Itot Itot Itot Itot

V Hz A A A A

QSV 205-345 380 60

IEC 18,4 20,4

QSV 205-345 400 50

QSV 205-345 460 60

IEC/

CSA/UL

15,2 16,9

QSV 205-345 200 50

IEC

QSV 205-345 230 60

CSA/UL

QSV 205-345 500 50

400

IEC

14,0 17,4 15,5 19,4

QSV 205-345 575 60

460

CSA/UL

12,1 15,2 13,5 16,9

QSV 430 380 60

IEC 25,2 28,0

Quincy Vacuum Pump-QSV Series 97

Loading...

Loading...