Section VII - Problem Solving

The pump

cannot reach

stated vacuum

Membrane of vacuum control valve defect Replace membrane

Vacuum pump element out of order Consult Quincy

Air leakage Check the process lines for leakage

Pressure switch

trips

Oil separator elements clogged Have elements replaced

Oil filter clogged Have oil lter replaced

Discharge clogged Check couplings and outlet

Bypass valve or oil injection system clogged Have bypass valve cleaned or replaced.

Clean oil injection system

Pressure switch out of order Replace pressure switch

Vacuum pump

element outlet

temperature

above normal

Oil level too low

Check and correct, see Operation in-

structions / During operation

Insufficient cooling air or cooling air tem-

perature or relative humidity is too high

Check for cooling air restriction or im-

prove ventilation of the vacuum pump

room. Avoid recirculating of cooling air.

If installed, check capacity of vacuum

pump room fan

Oil cooler clogged Clean cooler

Oil filter clogged Replace oil filter

Scavenge line clogged Clean scavenge line

By-pass valve malfunctioning Have valve tested

Degraded oil

Check service intervals, see Preventive

maintenance schedule

Temperature of pressure air too high Check process air temperature

Vacuum pump element out of order Consult Quincy

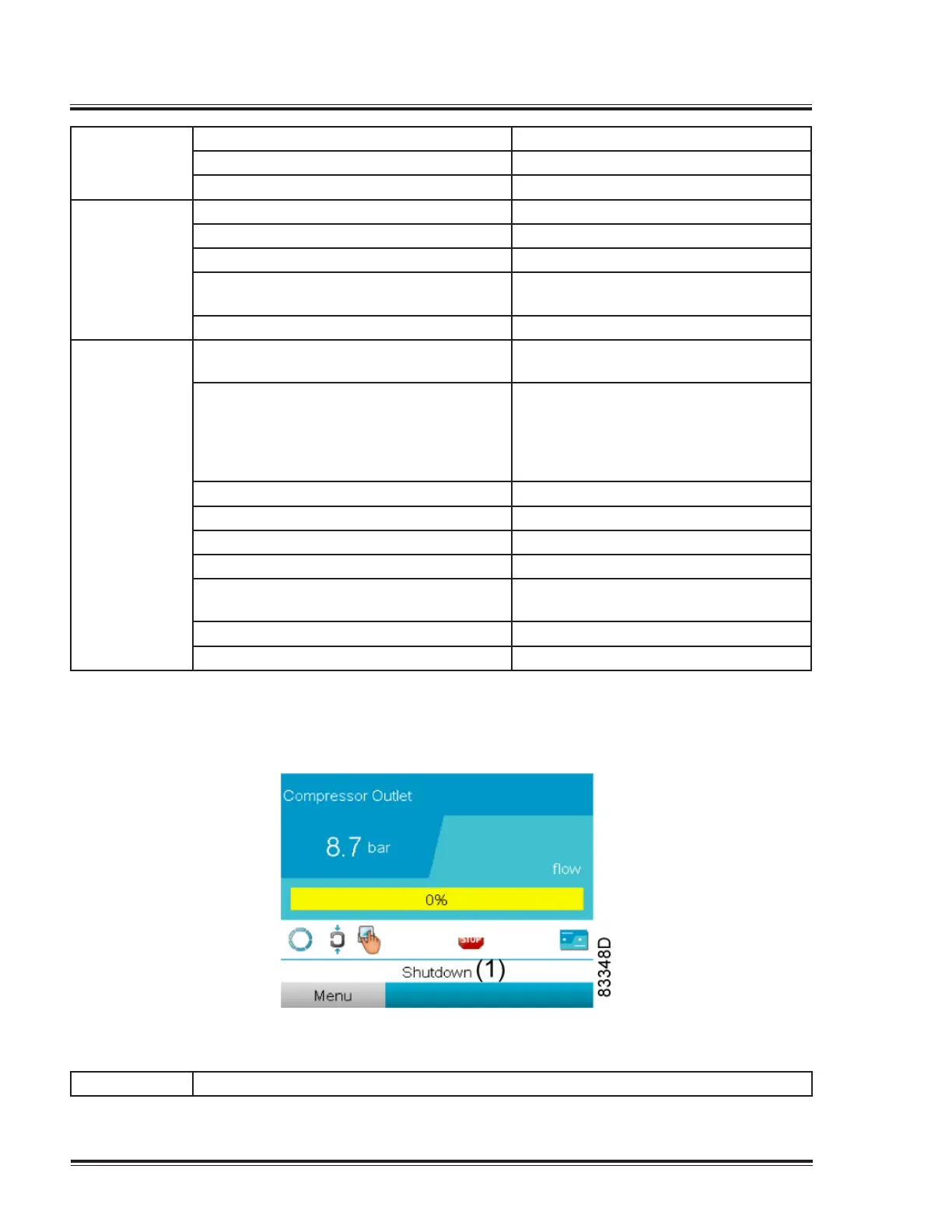

Converter fault codes

If a problem is detected by the converter, a specic code (Main motor converter alarm)

will appear on the Airlogic display, together with a fault code. Below table lists the most

important error codes. If another code appears, please contact Quincy.

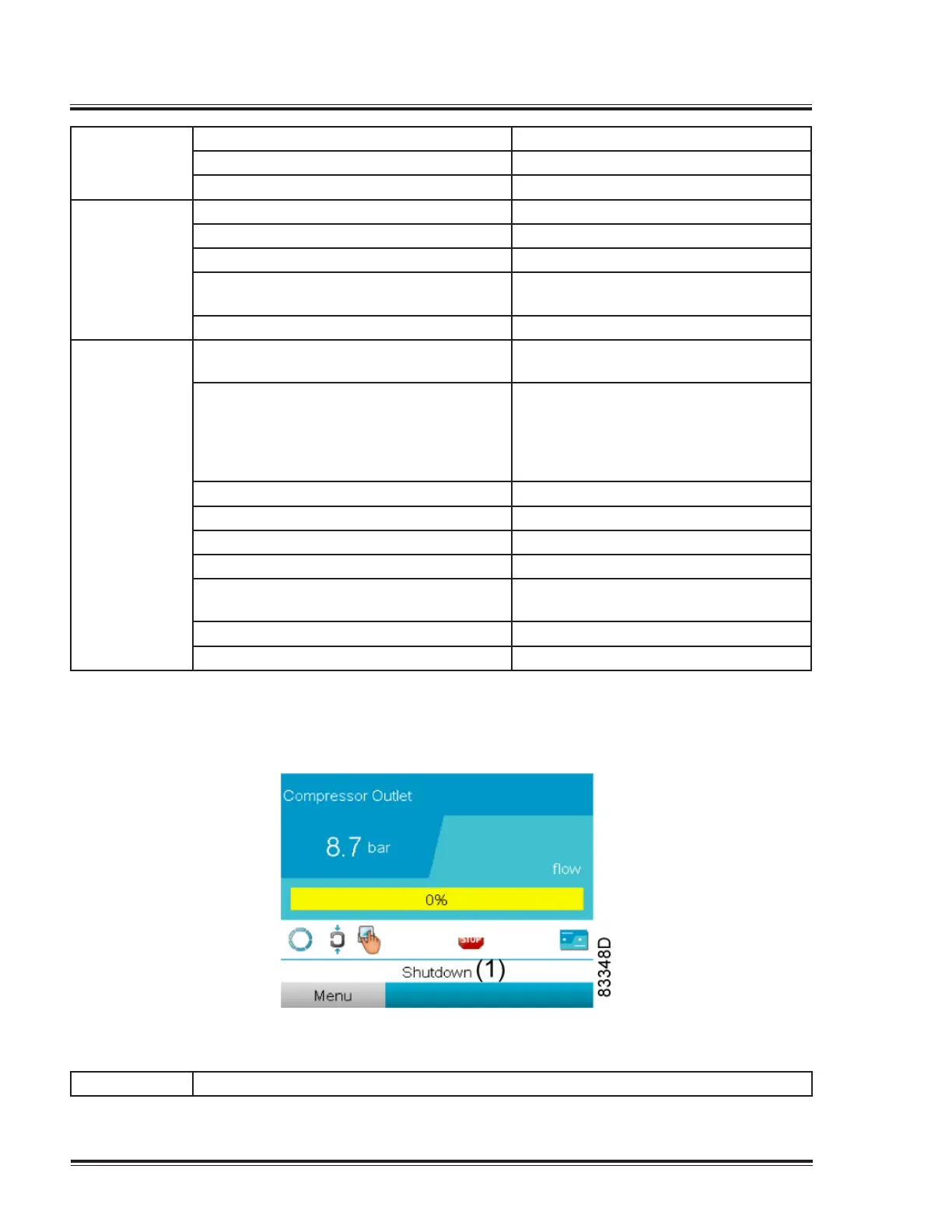

Typical display when the vacuum pump is stopped by a shutdown

(1) Shutdown

88 Quincy Vacuum Pump-QSV Series

Loading...

Loading...