20

INSTALLATION

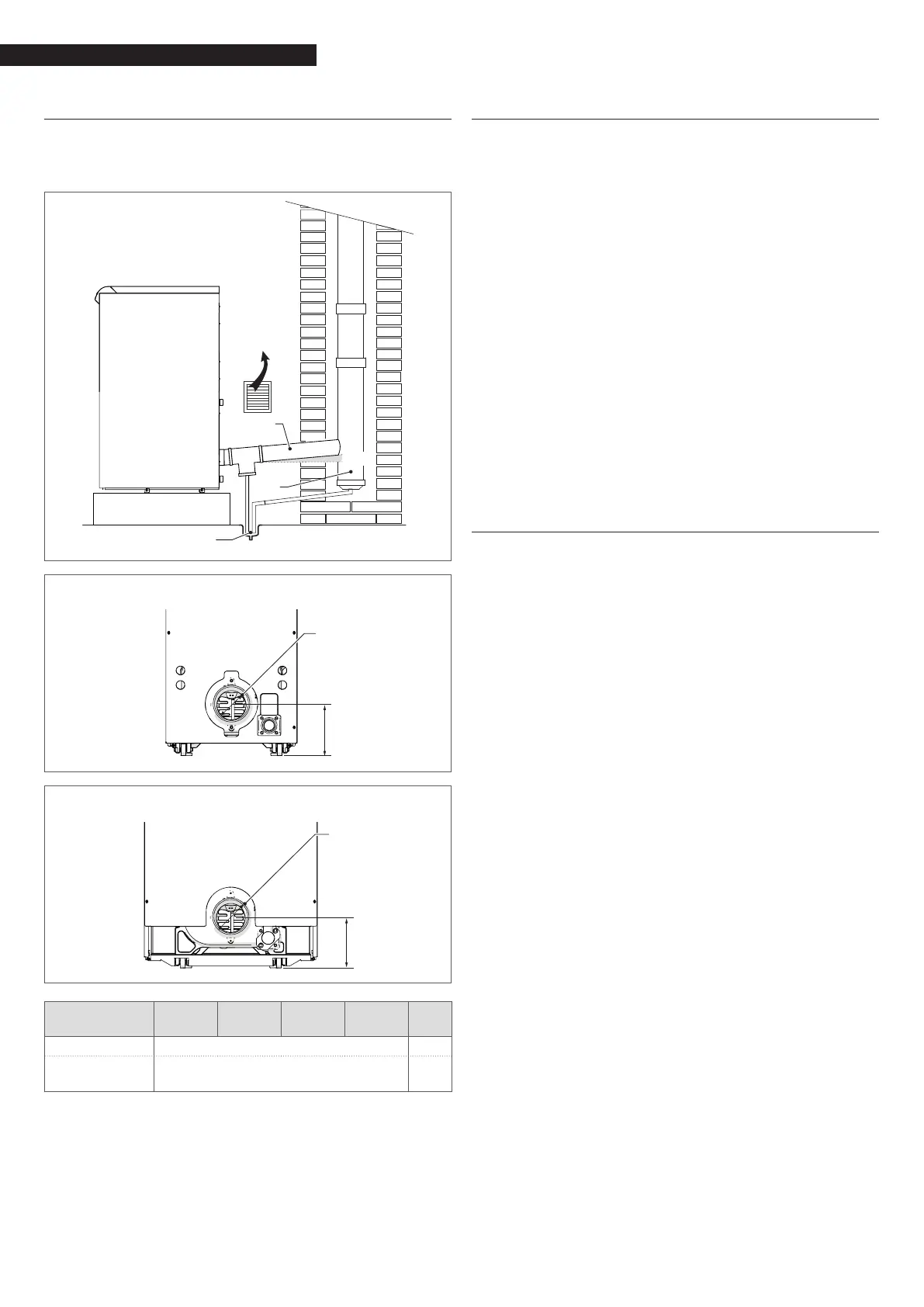

2.9 Combustion gas exhaust

The ue pipe (1) and the connection to the stack (2) must be

made in conformity to the laws, standards and regulations ap-

plicable in the place of installation.

2

≥5°

1

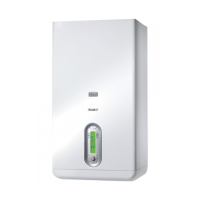

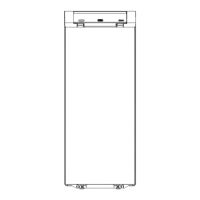

GITRÈ

E

G

GITRÈ B/100

E

G

DESCRIPTION GITRÈ 4 GITRÈ 5 GITRÈ 6

GITRÈ 5

B/100

E 178 mm

G (ue gas ex-

haust tting)

126-139 concentric Ø

GITRÈ boilers derive their comburent air from the room in which

they are installed. Suitable air vents must therefore be provided

in compliance with applicable laws and standards.

0

Do not obstruct or restrict the air vents in the room where

the boiler is installed. Adequate ventilation is essential for

correct combustion and functioning.

2.9.1 Technical specications of stack

The stack must satisfy the following requirements::

− It must be constructed from materials that are imper-

meable to ue gases and that offer lasting resistance to

mechanical stress, heat and the action of the products of

combustion and condensate

− It must be vertical, free of restrictions and contain bends

of no more than 45°

− It must be suitable for the specic operating conditions

of the boiler and must be CE marked (EN1856-1, EN1443)

− It must be of adequate dimensions to ensure draught

and venting properties suitable for the needs of the boil-

er (EN13384-1)

− It must have adequate external insulation to prevent

condensation and the cooling of ue gases

− the stack must have a dedicated condensate drain sys-

tem at the bottom.

9

The diameter of the stack must never be smaller than that of

the ue pipe from the boiler.

9

In conguration B23, the stack must guarantee the mini-

mum draught specied by applicable technical standards,

assuming zero pressure at the boiler's ue gas exhaust.

2.9.2 Connection to the stack

The boiler must be connected to the stack using rigid ue pipes

that are resistant to heat, condensate and mechanical stress. All

joins must be sealed and the nished ue must be insulated.

Only use materials that are suitable for this purpose, e.g. stain-

less steel.

The near-horizontal section of ue pipe must have a slope of at

least 5° towards the boiler and must also be properly insulated.

In long near-horizontal sections of ue pipe (L>1 m), install a

condensate drain system near the boiler exhaust (as shown in

the gure) to drain off any condensate forming in this section

of ue.

The diameter of the stack must always be greater than that of

the ue pipe from the boiler's exhaust tting. To change direc-

tion, use a T section with an inspection cap to permit easy access

for cleaning inside the pipe. After cleaning, always make sure

that inspection caps are replaced tightly and that their seals are

undamaged and efcient.

9

Flue pipes must maintain a distance of at least 500 mm

from ammable or heat sensitive construction materials.

9

Joins must be sealed with materials that are resistant to

acid condensate and to the high temperatures of the boil-

er's ue gases.

9

When installing ue pipes, always bear in mind the direc-

tion of the ue gases and of possible condensate ows.

9

Inadequate or badly dimensioned stacks and ues can in-

crease combustion noise, cause condensation problems

and affect combustion parameters.

9

Uninsulated ues are potentially dangerous and can cause

burns.

Loading...

Loading...