Rockwell Automation Publication 2198-UM005C-EN-P - February 2022 57

Chapter 4 Connector Data and Feature Descriptions

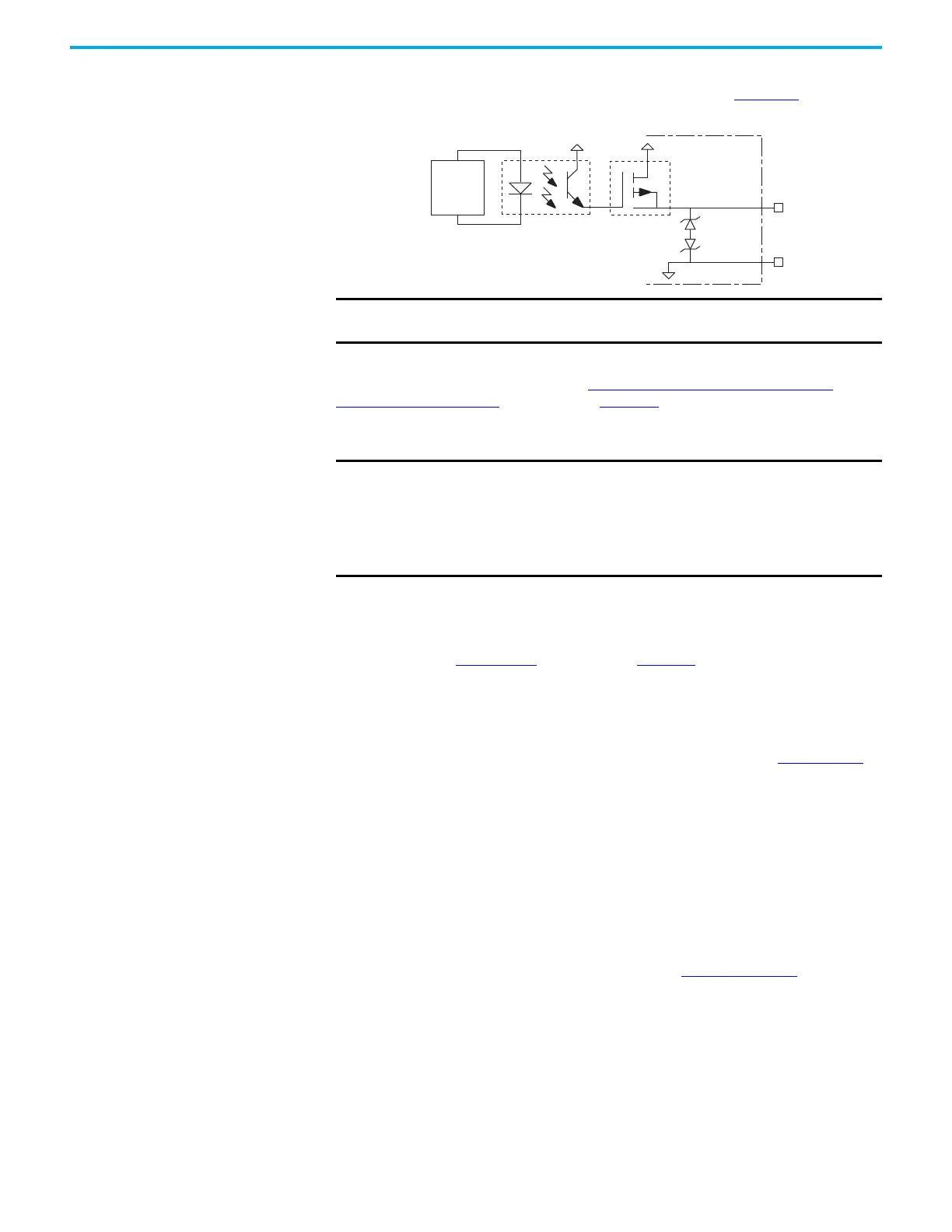

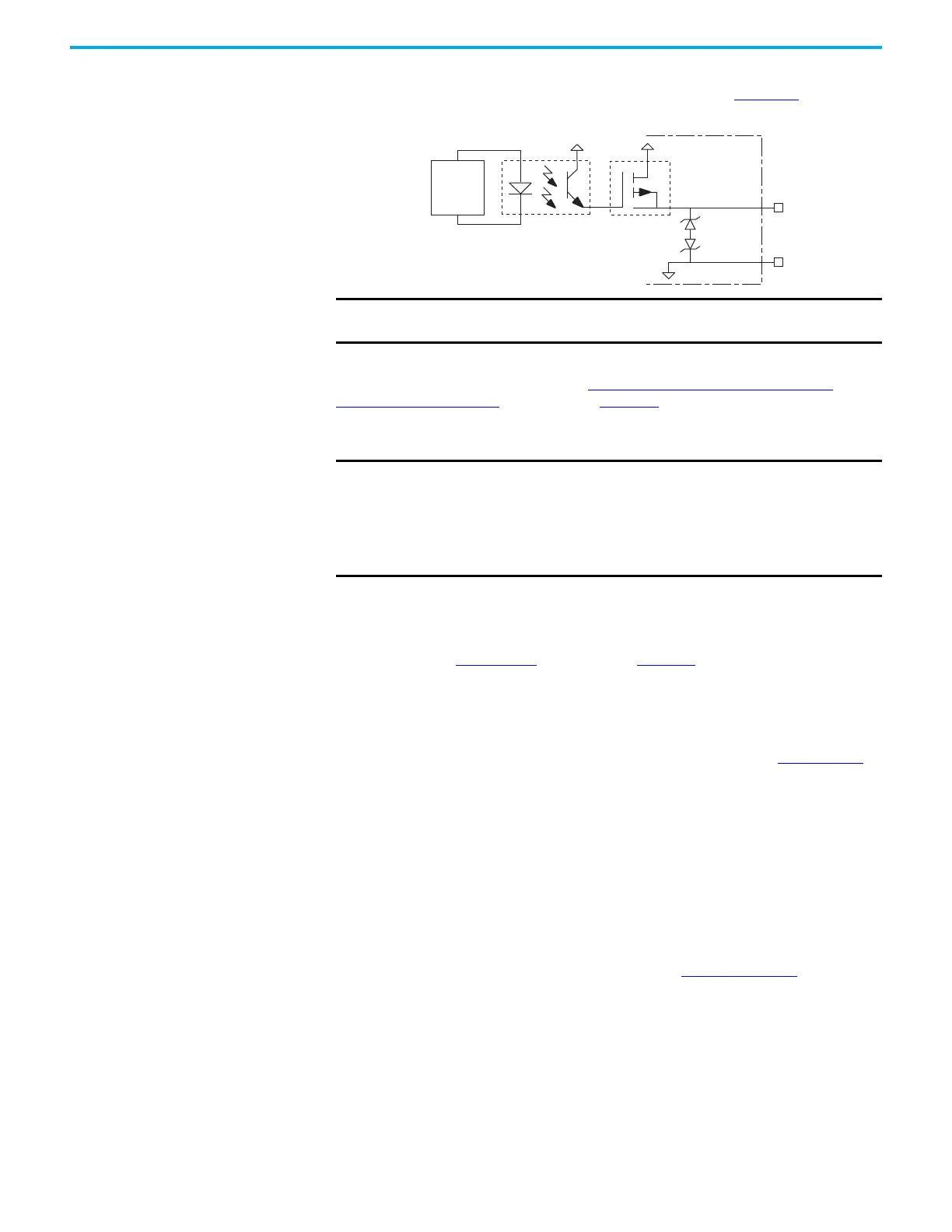

Two connections (MBRK+ and MBRK-) are required for the motor brake

output. Connections are rated for 2.25 A @ +24V (refer to Figure 29).

Figure 29 - Motor Brake Circuit

Control of the solid-state relay to release the motor brake is configurable in the

Logix Designer application (refer to Configure SPM Motor Closed-loop

Control Axis Properties beginning on page 122). An active signal releases the

motor brake. Turn-on and turn-off delays are specified by the

MechanicalBrakeEngageDelay and MechanicalBrakeReleaseDelay settings.

Follow these steps to control a holding brake using a Motion Servo Off (MSF)

command.

1. Wire the mechanical brake according to the appropriate interconnect

diagram in Appendix

A beginning on page 169.

2. Enter the MechanicalBrakeEngageDelay and Mechanical

BrakeReleaseDelay times in the Logix Designer application.

Refer to Axis Properties>Parameter List. The delay times must be from

the appropriate motor family brake specifications table in the Kinetix

Rotary Motion Specifications Technical Data, publication KNX-TD001

.

3. Use the drive stop-action default setting (Current Decel & Disable).

Refer to Axis Properties>Actions>Stop Action in the Logix Designer

application.

4. Use the motion instruction Motion Axis Stop (MAS) to decelerate the

servo motor to 0 rpm.

5. Use the motion instruction Motion Servo Off (MSF) to engage the brake

and disable drive.

For more information on how the servo motor holding-brake option can be

used to help keep a load from falling see Vertical Load and Holding Brake

Management Application Technique, publication MOTION-AT003

.

ISP772

MBRK+ (BC-1)

MBRK– (BC-2)

24V+ PWR

24V–

INT PWR

Kinetix 5300

Servo Drive

Control

Board

Inductive

Energy

Clamp

IMPORTANT Motor holding-brake switching frequency must not exceed

15 cycles/min.

IMPORTANT Holding brakes that are available on Allen-Bradley® rotary motors are

designed to hold a motor shaft at 0 rpm for up to the rated brake-holding

torque, not to stop the rotation of the motor shaft, or be used as a safety

device.

You must command the servo drive to 0 rpm and engage the brake only

after verifying that the motor shaft is at 0 rpm.

Loading...

Loading...