00809-0100-4835 Rev BD

2-5

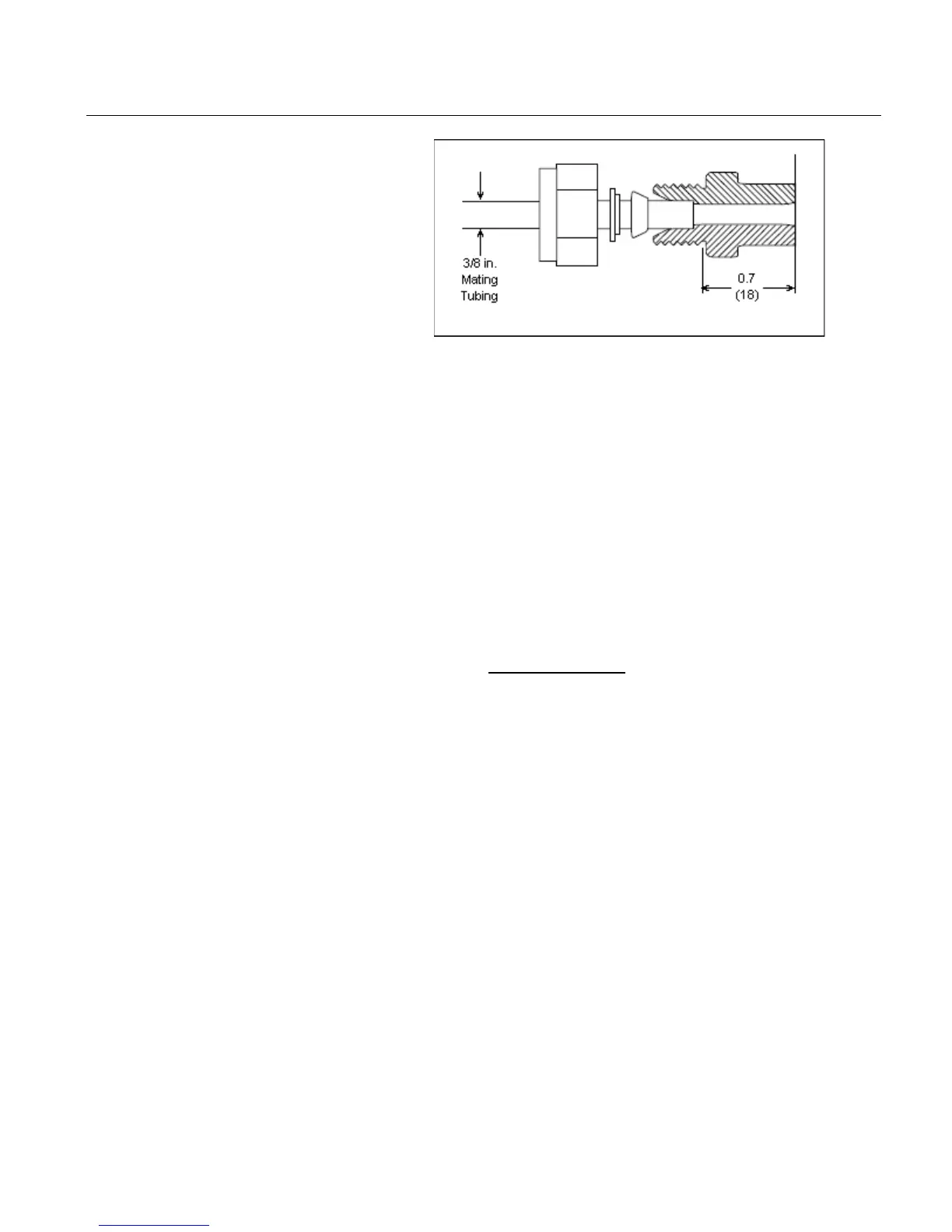

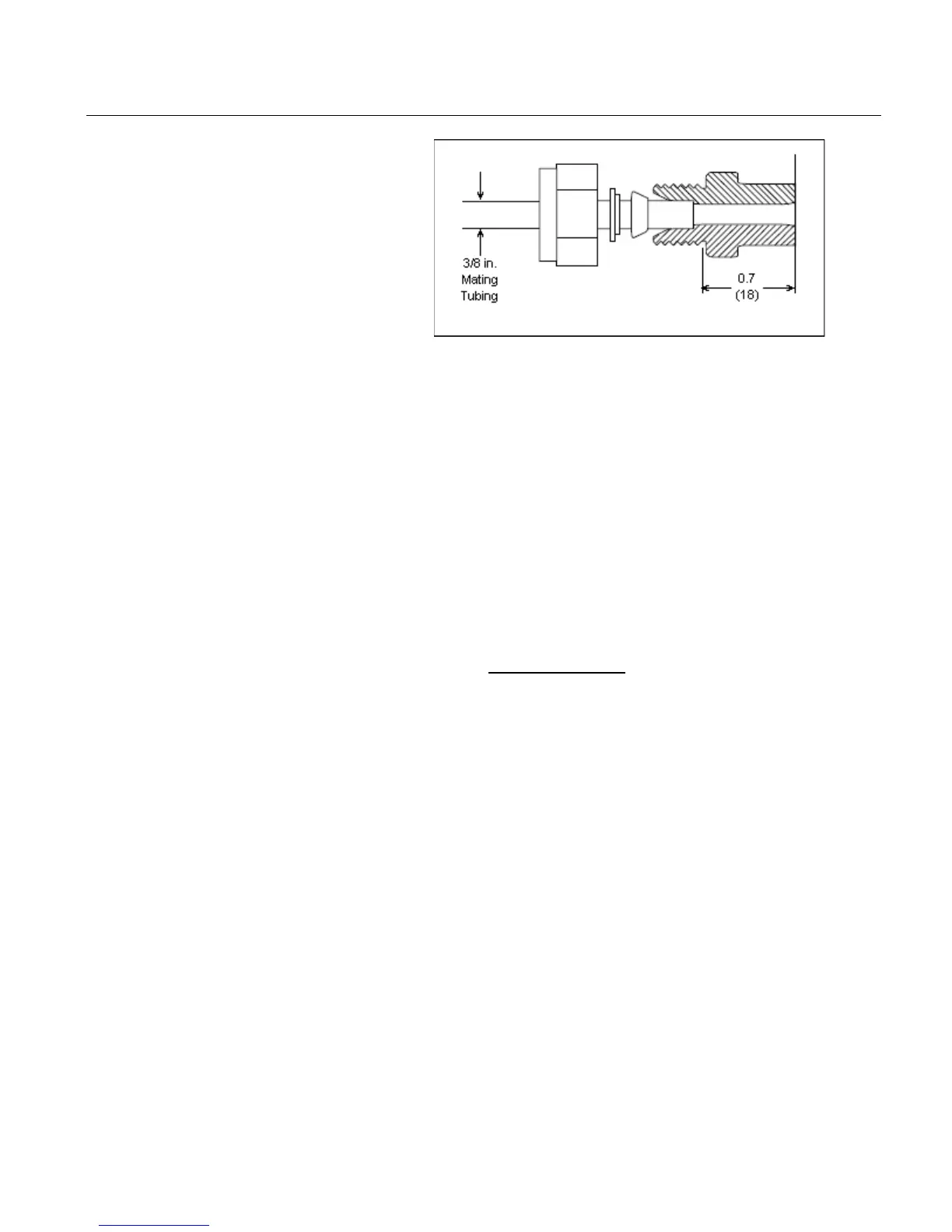

Figure 2-1 – Swagelok™

Compression Fitting Detail

The Swagelok™ tube fittings come completely assembled and are

ready for immediate use.

Do not disassemble them before use

because dirt or foreign materials may get into the fitting and cause

le

aks. Insert the tubing into the Swagelok™ tube fitting, make sure the

tubing rests firmly on the shoulder of the fitting and the nut is finger

tight. Tighten the nut one

-and-one-quarter turns. Do not over-tighten.

To reconnect, insert the tubing with p

re-swaged ferrules into the fitting

until the front ferrule sits in the fitting. Tighten the nut by hand, then

rotate one

-quarter turn more or to the original one-and-one-quarter tight

position. Then snug it slightly with a wrench.

nformation regarding the specifications and use of

Swagelok™ tube fittings, refer to:

Fittings Catalog MS-01-140

“Gaugeable Tube Fittings and Adapter Fittings”

www.swagelok.com

If drain/vent valves are opened to

bleed process lines, torque stems to

-2 in Section 5 Maintenance and Troubleshooting

The piping between the process and the transmitter must accurately

transfer the pressure to obtain accurate measurements. There are fi

ve

possible sources of error: pressure transfer (such as obstruction), leaks,

friction loss (particularly if purging is used), trapped gas in a liquid line

or liquid in a gas line and density variations between the legs.

The best location for the transmit

ter in relation to the process pipe

depends on the process itself. Use the following guidelines to

determine transmitter location and placement of impulse piping:

• Keep impulse piping as short as possible

• For liquid service, slope the impulse piping at least 1 inch per

foot (8 cm per m) upward from the transmitter toward the

process connection

• For gas service, slope the impulse piping at least 1 inch per foot

(8 cm per m) downward from the transmitter toward the process

connection

• Avoid high points in liquid lines and low points in gas lines

• Make sure both impulse legs are the same temperature

Dimensions are nominal in inches (mm)

Loading...

Loading...