00809-0100-4835 Rev BD

July 2016

5-16

1. Conduct hydrostatic testing to 150% of maximum working

pressure or 2,000 psi (13.79 MPa), whichever is greater.

Conduct the testing for a duration of ten minutes minimum, and

visually verify that there is no water leakage from the transmitter,

including the flange/process connection interface and the flange/

sensor module interface.

2. Calibrate the transmitter per Section 3 Calibration in this

manual.

3. Clean the “wetted parts” to < 1 ppm chloride content.

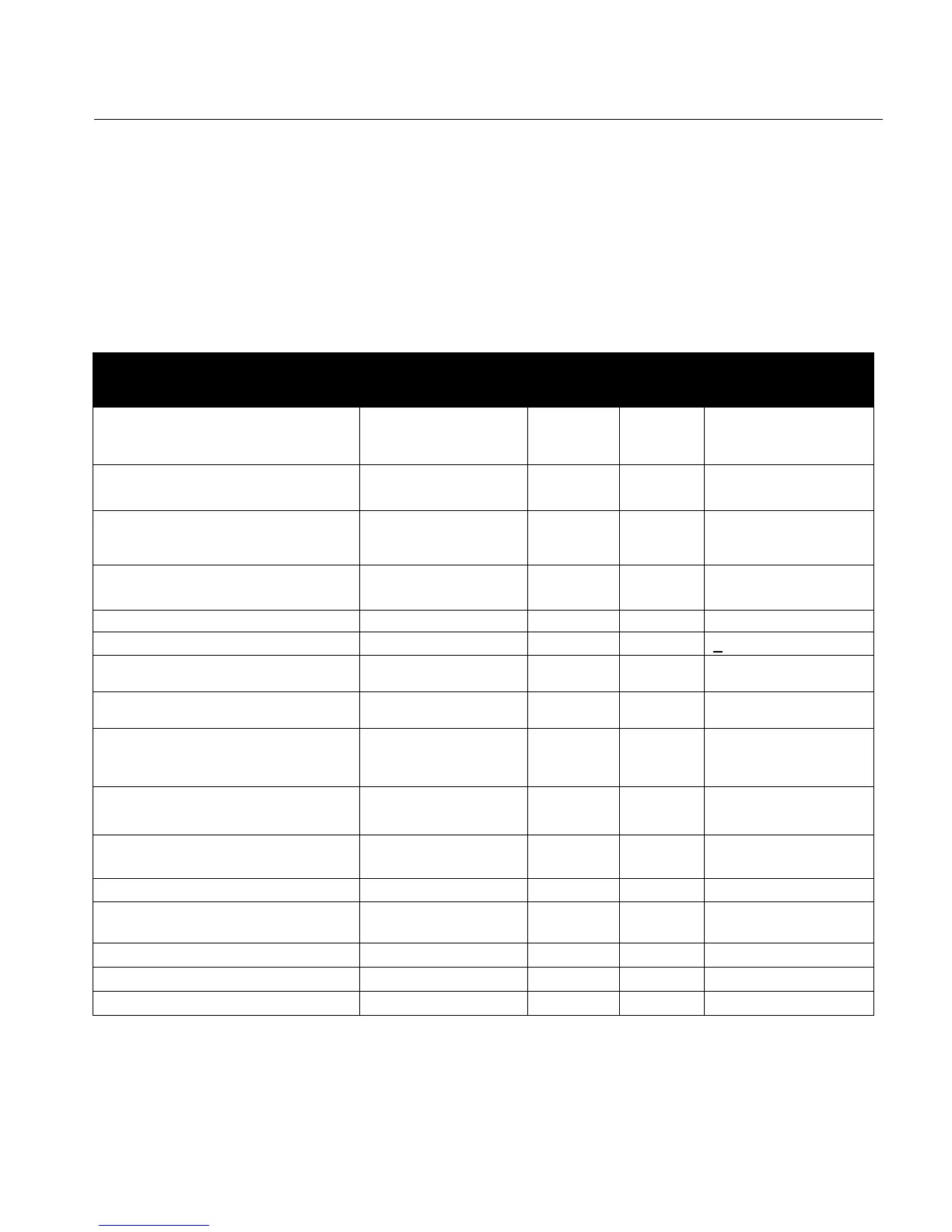

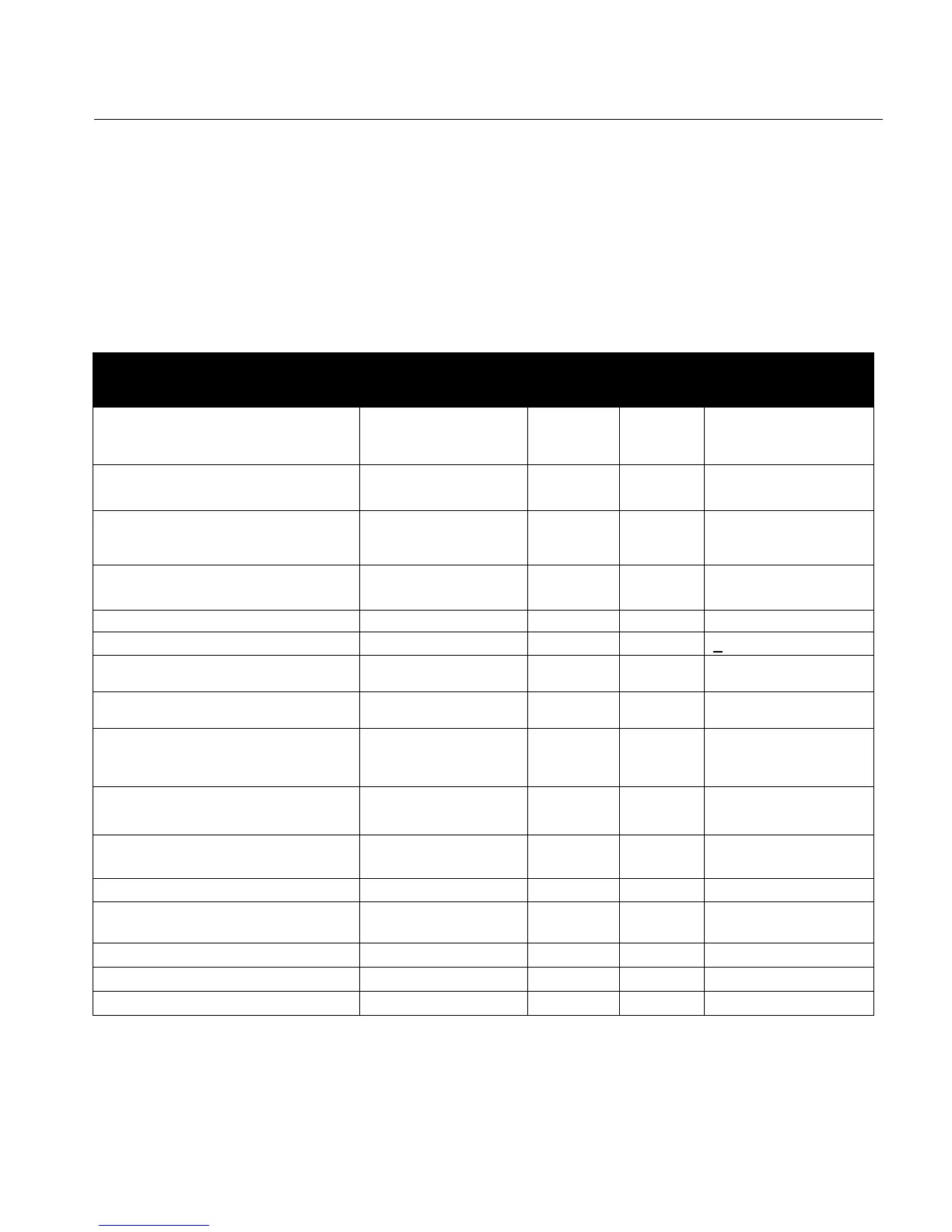

Table 5-2 – Torque References

ITEM(S) TO BE TORQUED

3152 TORQUE

VALUE

TORQUE

TORQUE

TOLERANCE

Panel Bracket to Mounting Surface

19 ft-lb (26 N-m) same same ±1 ft-lb (1.4 N-m)

Traditional Flange

Pipe Bracket to Mounting Pipe Bolts

19 ft-lb (26 N-m) same same ±1 ft-lb (1.4 N-m)

Transmitter to Bracket Bolts

(Both Carbon Steel and SST)

21 ft-lb (29 N-m) same same ±1 ft-lb (1.4 N-m)

Flange Bolts

See Process Flange

Reassembly section

same same

See Process Flange

Reassembly section

Valve Seats or Plugs 200 in-lbs (22.6 N-m) same same + 1 ft-lb (1.4 N-m)

Swagelok™ Process Fitting

See installation

instructions

same same -

Covers

See installation

instructions

same same -

Conduit Plug

( ½” NPT housing threads)

200 in-lb (22.6 N-m) same N/A ±1 ft-lb (1.4 N-m)

Conduit Plug

(M20 housing threads)

200 in-lb (22.6 N-m) same N/A ±1 ft-lb (1.4 N-m)

Conduit Seal Fitting

See Manufacturer’s

instructions

same same same

Terminal Block Mounting Screws

Electronics Assembly Mounting

Screws

7 in-lbs (0.8 N-m) same same ±1 in-lb (0.1 N-m)

Internal Ground Screw 7 in-lbs (0.8 N-m) same same ±1 in-lb (0.1 N-m)

External Ground Screw 8.9 in-lbs (1.0 N-m) same same ±1 in-lb (0.1 N-m)

Terminal Screw 7 in-lbs (0.8 N-m) same same ±1 in-lb (0.1 N-m)

Loading...

Loading...