00809-0100-4835 Rev BD

July 2016

5-14

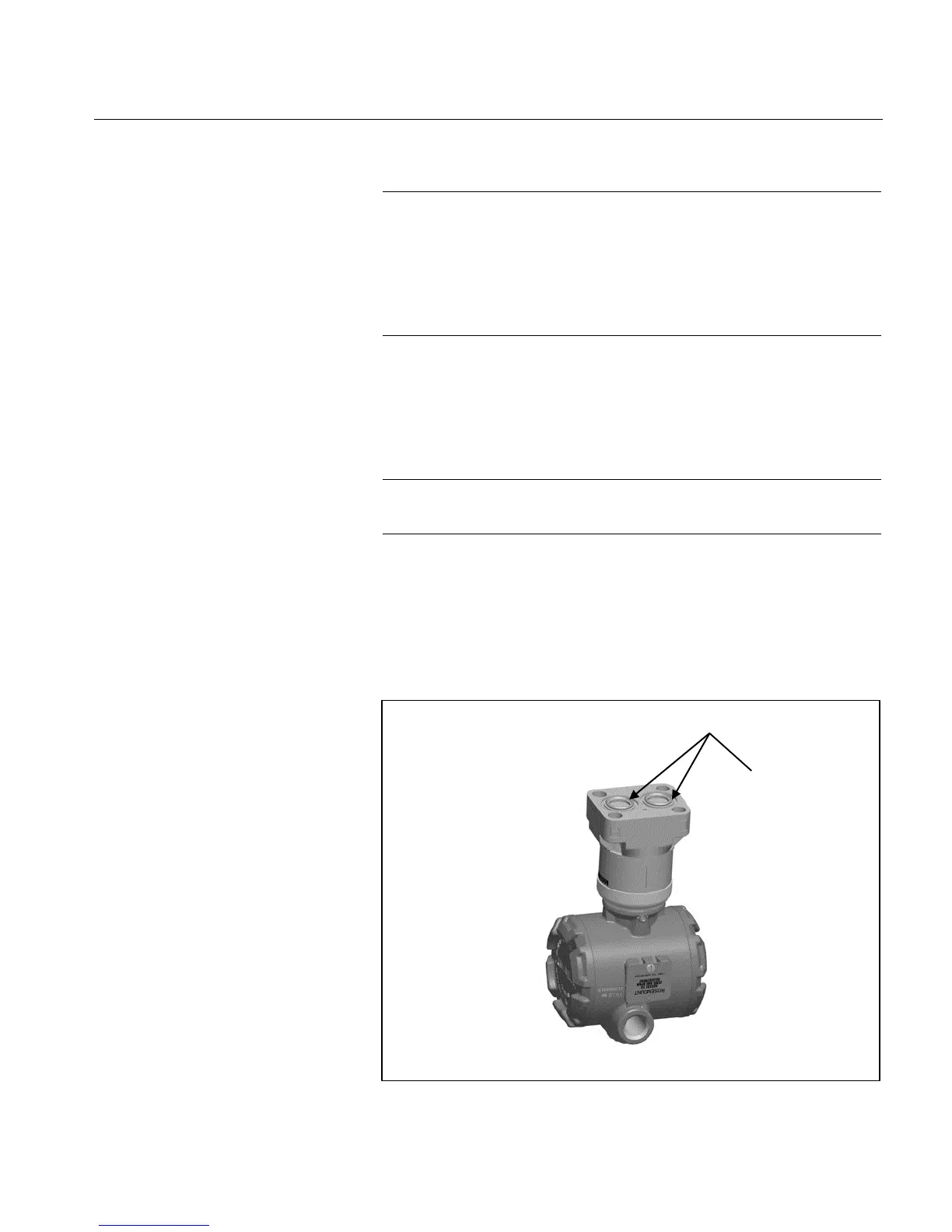

Electronics Housing Cover

Installation

1. Inspect the housing (5) and cover (1) threads to ensure they are

free of foreign material. If foreign material is present, remove it.

Use of thread lubricant on the cover is recommended to reduce

galling between the cover and housing. Covers are shipped from the

factory pre-lubricated with the qualified dry lubricant. Normally, dry

lubricant should not need to be re-applied; however, thread lubricant

may be re-applied if desired. For reference, the transmitters were

qualified using Lubriplate #5555

®

(aluminum covers) and Electrofilm

TM

2. Carefully replace each cover, ensuring that each contains a cover

o-ring (2) (See Preliminary Section above). Caution should be

taken that electrical wires do not interfere with cover installation

so wire damage does not occur. Tighten cover until its surface

and the housing surface are fully engaged metal-to-metal (see

Figure 2-9 in Section 2: Installation).

Once the cover is installed metal-to-metal, do not torque the cover

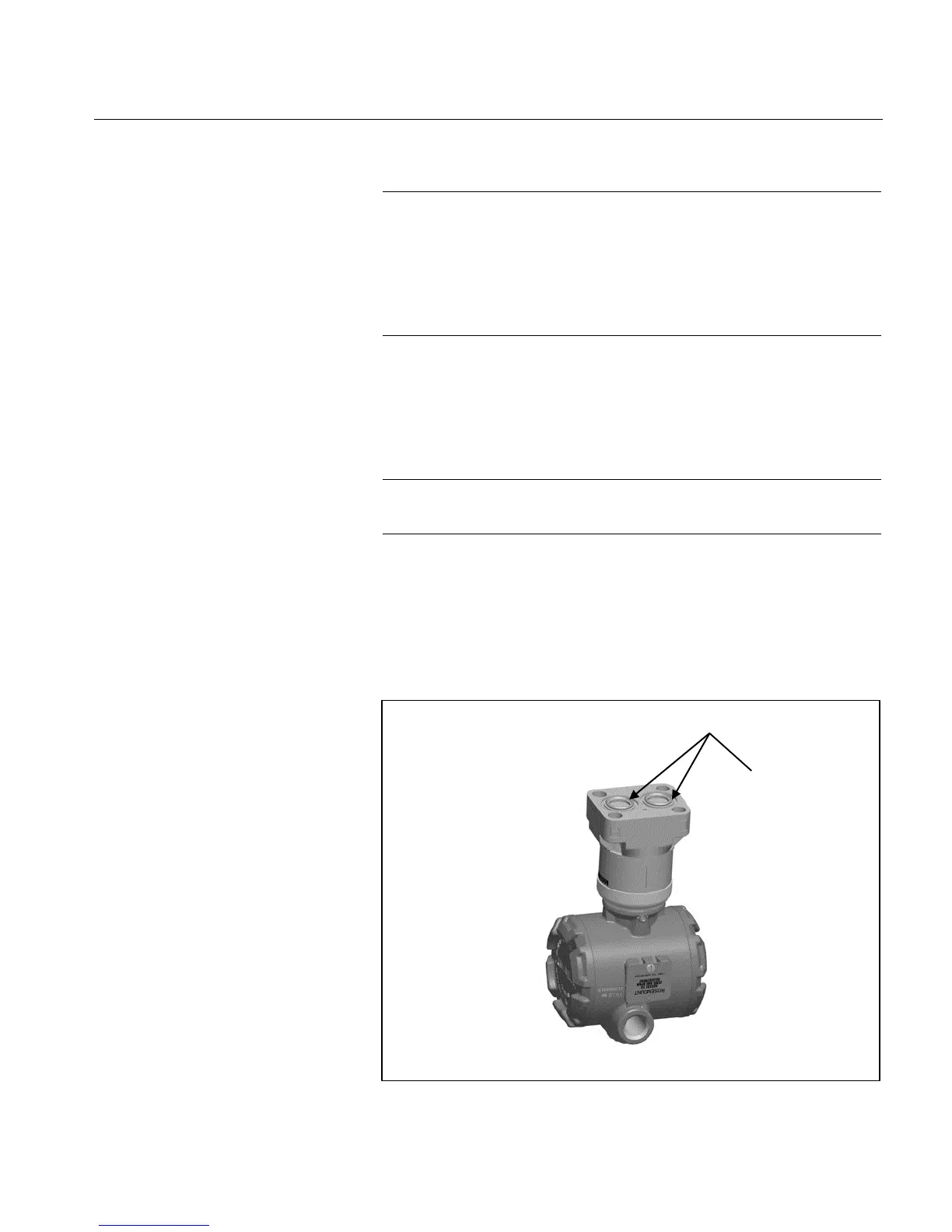

Process Flange Reassembly

1. Replace the process c-rings (9) with new c-rings if the flange (10)

was removed. Carefully place one c-ring in each of the two weld

rings located on the isolating diaphragms of the sensor module

(8) as shown in Figure 5-11.

2. Carefully place the process flange on the sensor module. Take

care not to disturb the c-rings or damage the isolating

Figure 5-11 – Process C-rings

c-rings into the

grooves of

metal welded

Loading...

Loading...