00809-0100-

5-17

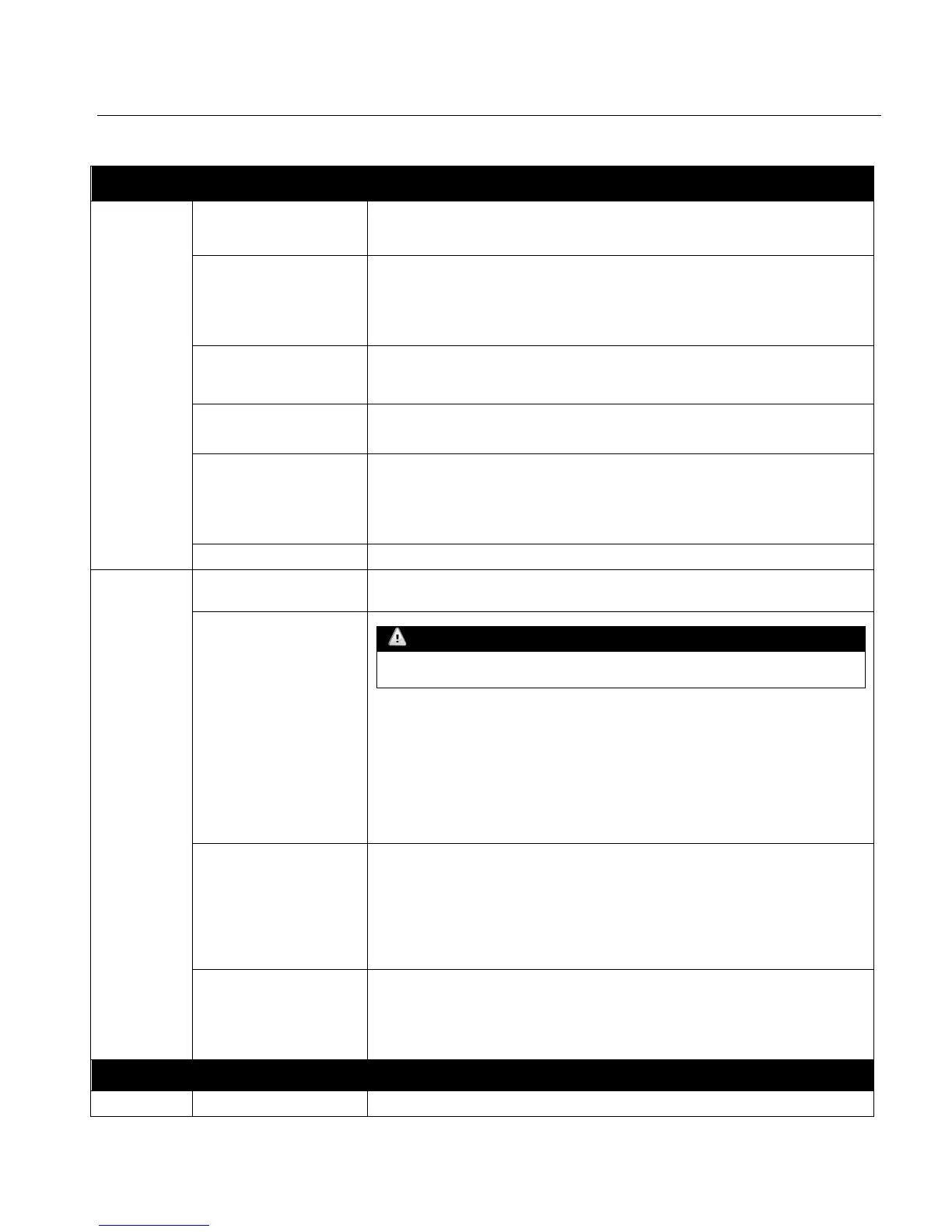

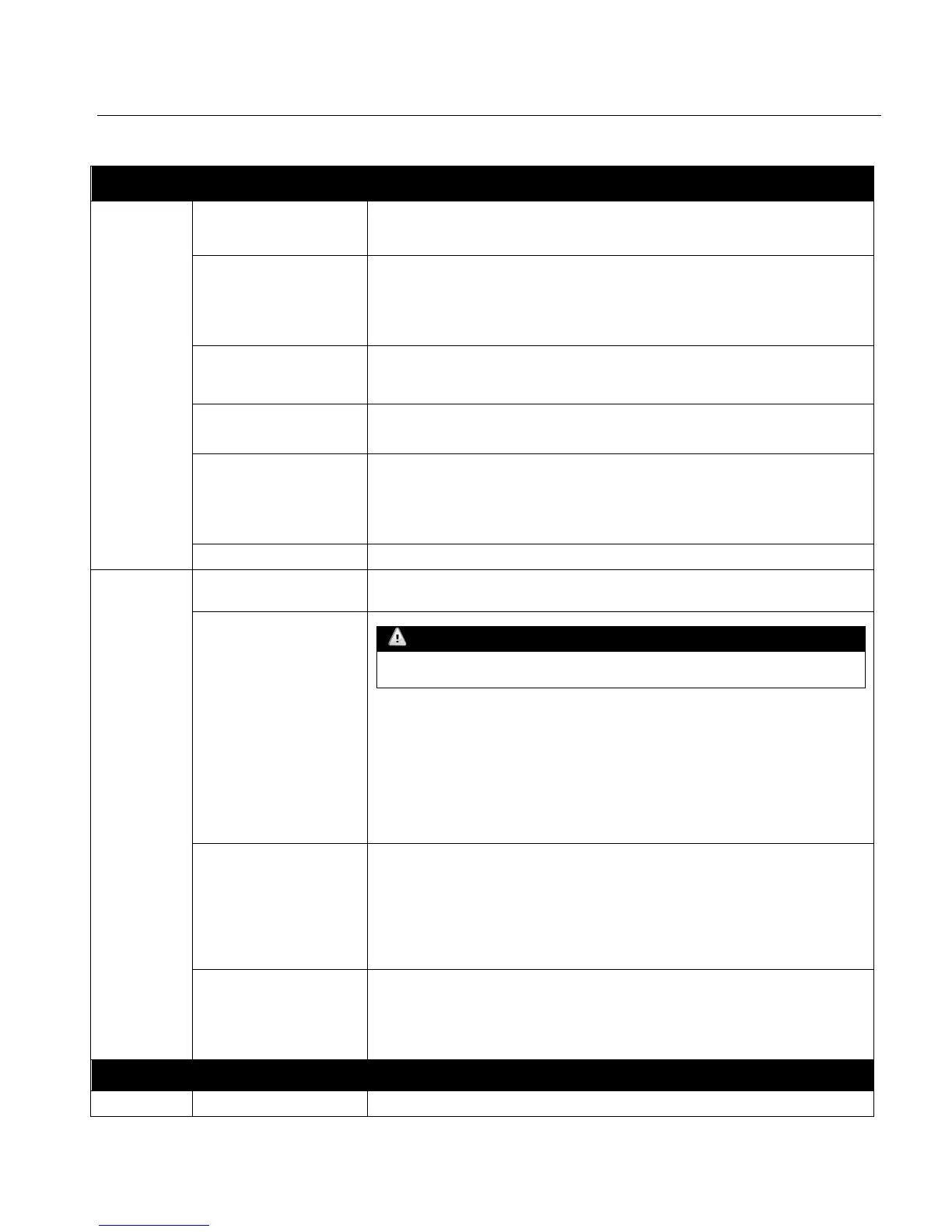

Table 5-3 – Troubleshooting

Symptom Potential Source Corrective Action

High Output

Primary Element

Check for restrictions at primary element, improper installation or poor

condition. Note any changes in process fluid properties that may affect

Impulse Piping

Check for leaks or blockage.

Ensure blocking locking valves are fully open.

Check for entrapped gas in liquid lines, or liquid in dry lines.

Ensure that density of fluid in impulse line is unchanged.

Check for sediment in transmitter process flanges.

Transmitter

Electronics

Make sure that filter pins and the sensor module connections are

clean. If the electronics are still suspect, substitute new electronics.

Transmitter

Electronics Failure

Determine faulty circuit board by trying spare electronics assembly or

terminal block assembly. Replace faulty assembly.

Sensor Module

NOTE: See Sensor Module Checkout section. The sensing element

is not field repairable and must be replaced if found to be defective.

See Disassembly Procedure for instructions on disassembly. Check

for obvious defects (i.e. punctured isolating diaphragm, etc.) and

contact Rosemount Nuclear Instruments, Inc.

Power Supply Check the power supply output voltage at the transmitter.

Low Output

or No

Output

Primary Element

Check the insulation and condition of primary element.

Note any changes in process fluid properties that may affect output.

Loop Wiring

Check for adequate voltage to the transmitter.

Check the milliamp rating of the power supply against the total current

being drawn for all transmitters being powered.

Check for shorts and multiple grounds.

Check for proper polarity at the signal terminal.

Check loop impedance.

Check wire insulation to detect possible shorts to ground.

Do not use more than 55 volts to check the loop, or damage to the

transmitter electronics may result.

Impulse Piping

Ensure that the pressure connection is correct.

Check for leaks or blockage.

Check for entrapped gas in liquid lines, or liquid in dry lines.

Check for sediment in transmitter process flanges.

Ensure that blocking valves are fully open and that bypass valves are

tightly closed.

Ensure that density of fluid in the impulse line is unchanged.

Transmitter

Electronics

Connections

Ensure that calibration adjustments are in allowable range.

Check for short in sensor leads.

Make sure filter pins are clean, and check the sensor module

connections.

If the electronics are still suspect, substitute new electronics.

Continued on Next Page

Test Diode Failures Replace terminal block.

Loading...

Loading...