COMEO - INSTRUCTIONS FOR THE USER

ROXELL - 001 - 4215

I-8

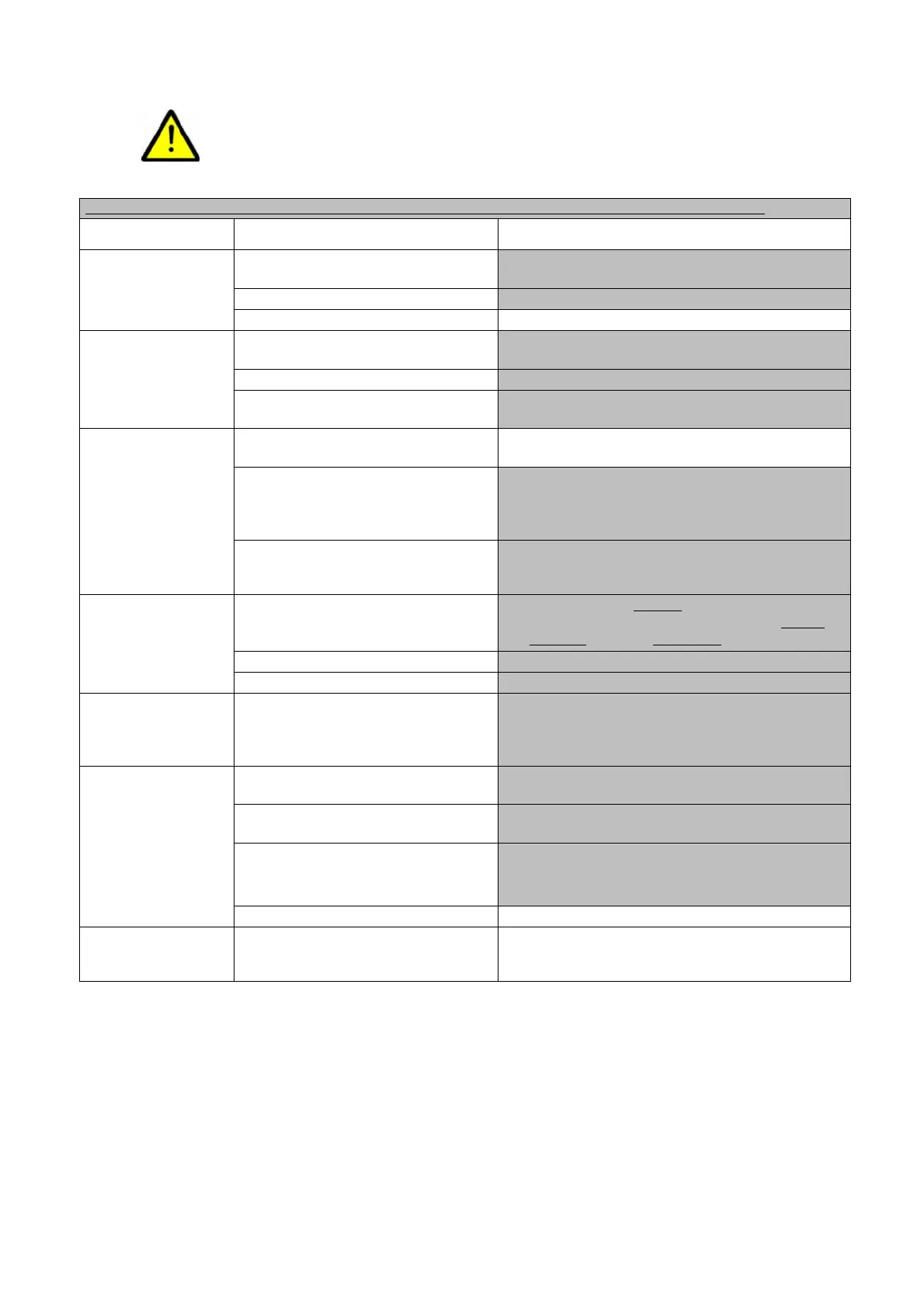

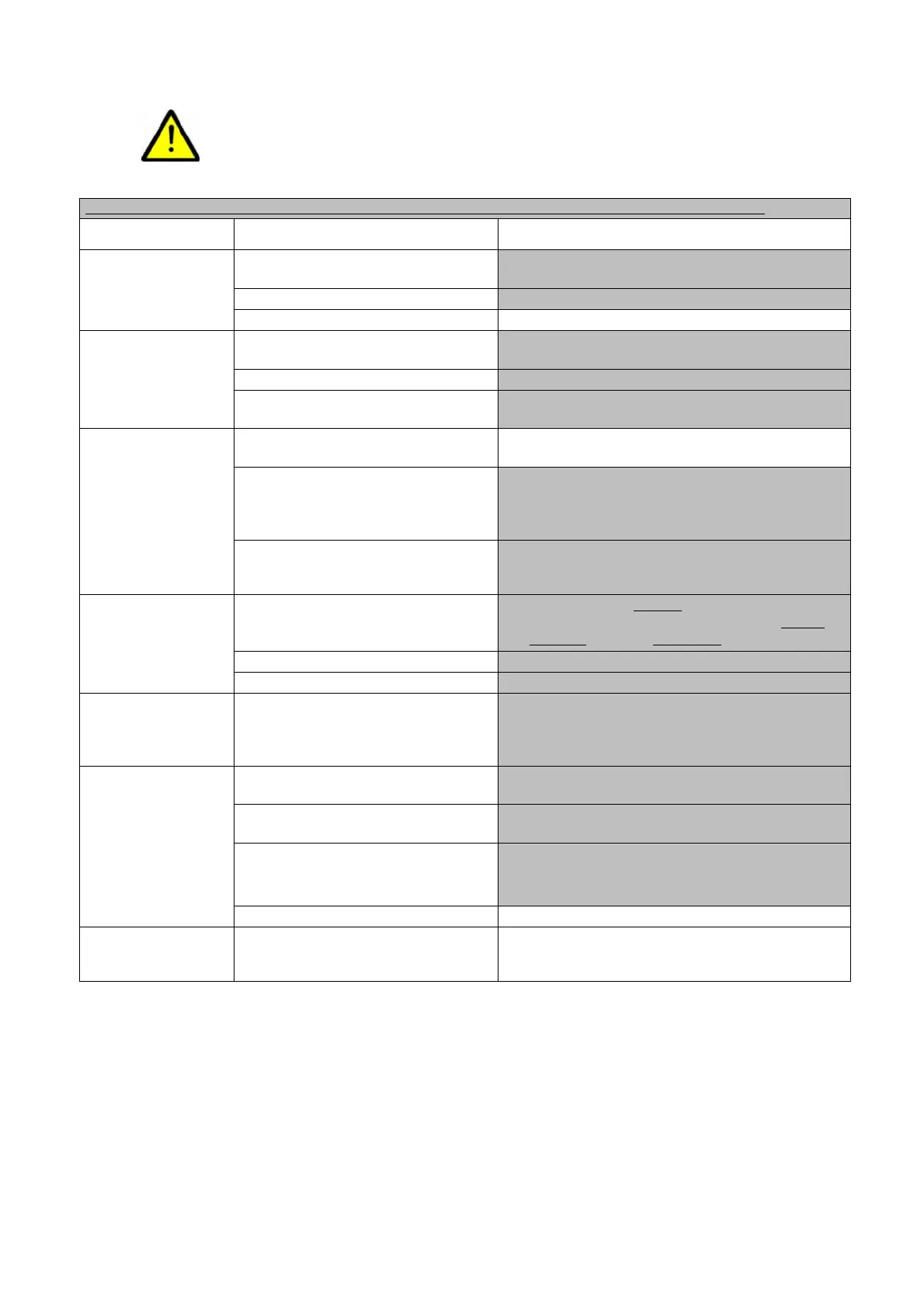

TROUBLE SHOOTING GUIDE

Switch off the main switch first.

Use personal protective equipment.

DANGER

ACTIONS IN GREY BACKGROUND MUST BE DONE BY A TECHNICALLY TRAINED PERSON.

PROBLEM CAUSE CORRECTIVE ACTION

1.None of the feeder

lines run.

No current. Replace defective fuses o r reset circuit breakers.

Check current supply to the house.

Defective time clock. Replace defective clock.

Time clock not properly set. Readjust tabs.

2.One/more lines do

not run.

Pans are empty

Wires from motor damaged. Measure current in motor wires. Replace wires if

defective.

Motor protection switched off. See points 3. & 4. Reset motor overload button.

Defective sensor/minimum switch

control unit or 100kg hopper.

Check control unit sensor or switch. Replace if

necessary.

3.Motor is o ften

overloaded.

Oil on auger overloads the motor. Clean the auger by running repeatedly 25kgs of

feed through the line.

Not enough current supply to the

motors.

Check current supply at motor location. Start the

motor. Measure start current on motors. Wiring

must be thick enough to guarantee good operation

of the system.

Object blocks the auger. Motor runs,

then stalls. Feed sticks to the tubes.

Check if there are no objects in the boot, the control

unit and the drop holes of the feeder pans. Remove

any objects.

4.Auger stalls.

Anchor bearing worn out or broken.

Replace bearing. Gently slide auger back into

thetubes.Don'tletitjumpback:yourfinger

or

the bearing

could be damaged.

Auger not enough stretched. Shorten the auger.

Object blocks the auger.

Remove the object.

5.Tubes / boot wear

rapidly,

much noise when

system runs.

Auger kinked or bent at the wear

point.

Auger end overlaps the anchor end.

Make sure not to kink the auger when using

gripping pliers. Auger must not overlap the anchor

end.

6.Not enough feed

supplied to fill up

the lines.

Flex-Auger drop holes are too small

or point upwards.

Make holes wider/turn tubes with holes

downwards.

Flow regulator in boot of feed supply

system blocks passage of the feed.

Adjust flow regulator to get a higher capacity.

Flex-Auger capacity is too low. Check the capacity of the Flex-Auger according the

specifications.

Check the installation of the Flex-Auger.

Notenoughtimesetonthetimeclock. Extend operation time per meal.

7.Feed drops

directly on the 12

fin support.

Pan not installed over the hole. Remove the top support. Install the pan ass'y over

theholeandthelips.

Loading...

Loading...