06-2017

CAP. 3

3 / 4

OPERA

Safety devices

EN

Fig. 1

Fig. 2

Fig. 3

3

1

2

4

2

3

2

1

4

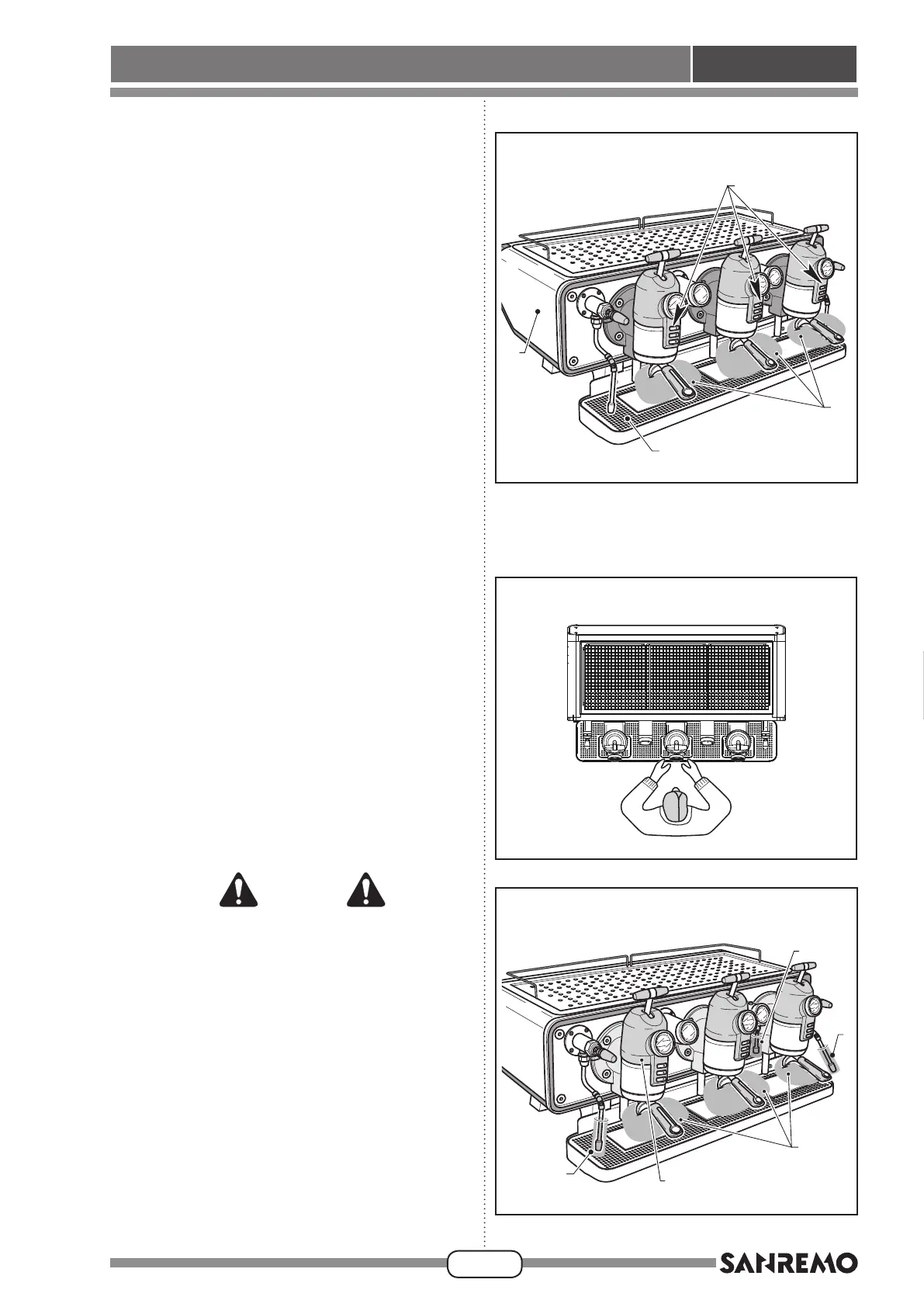

3.5.a - Mechanical safety devices (Fig. 1)

The mechanical safety devices are as follows:

- panel (1) enclosing all electrical/electronic compo-

nents and the boiler, fully closed by screws;

- working surface (2) tted with grille and tray to

collectuids;

- controls (3) located on the top part of the machine,

above the dispensing areas (4);

- relief valve on the boiler;

- checkvalveonthewaterline.

3.5.b - Electrical/electronic safety devices

The electrical/electronic safety devices are as follows:

- thermalbreakersonmotors;

- safety thermostats to monitor overheating;

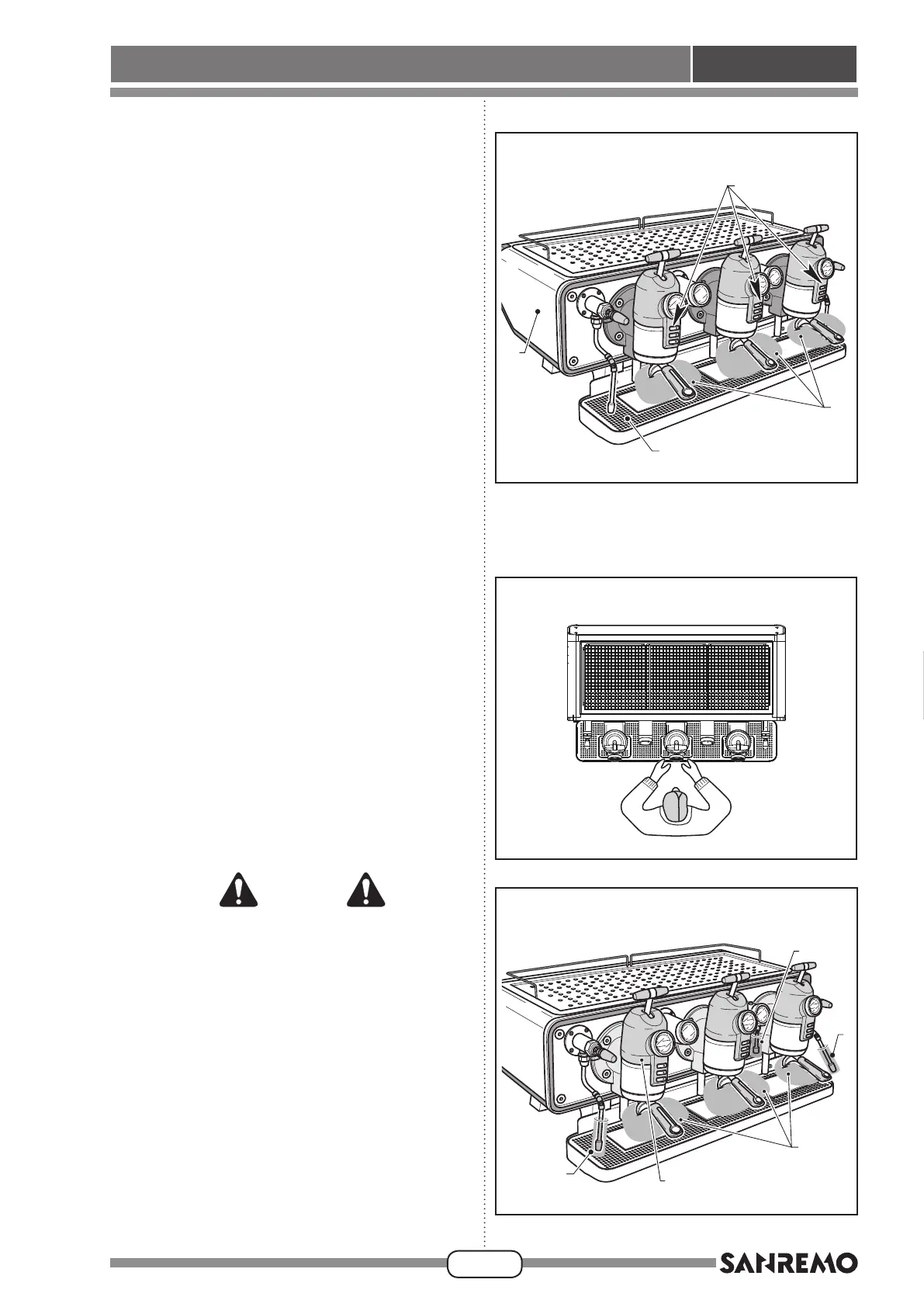

3.6 - OPERATOR AREAS (Fig. 2)

The machine is operated by only one operator, who

stands in front of the machine to prepare coffee and

otherhotdrinkswithease.

3.7 - AREAS WITH RESIDUAL RISK

(Fig. 3)

Residualriskareasareareasthatcannotbeprotected

duetothespecictypeofoperationtheyareusedfor;

on the coffee machine, these areas are as follows:

• the area (1) of the units when dispensing coffee;

• thesteamtap(2)whenheatingdrinks;

• the hot water dispensing area (3);

• the top part of the dispensing area (4); this hazard

is indicated by the relevant label.

Riskofburningispresentinallthreeareas.

3.8 - DANGEROUS AREAS

HAZARD

Dangerous areas are all areas inside the

machine, under the safety guards, where

the technician can operate when servicing

the machine.

These areas are accessible only by the

technician.

Loading...

Loading...