OM-610-1002-1 Operator’s Manual Rev 37

PDS-2010 SECTION 6 MAINTENANCE page 55

6.5 OPERATION AND MAINTENANCE LOGS

The 2010 is a robust piece of equipment, but the Parylene process requires periodic maintenance to be

performed. Cleaning of the Parylene from the chamber and cold trap probe is essential to avoid coating

build-up that otherwise would eventually destroy the performance of the system

Logs should be maintained on Daily Operation, Daily Maintenance, and Periodic Maintenance. Example

logs are shown below. Using and following the recommendations in these logs will maximize trouble free

operation of the PDS 2010 coating process.

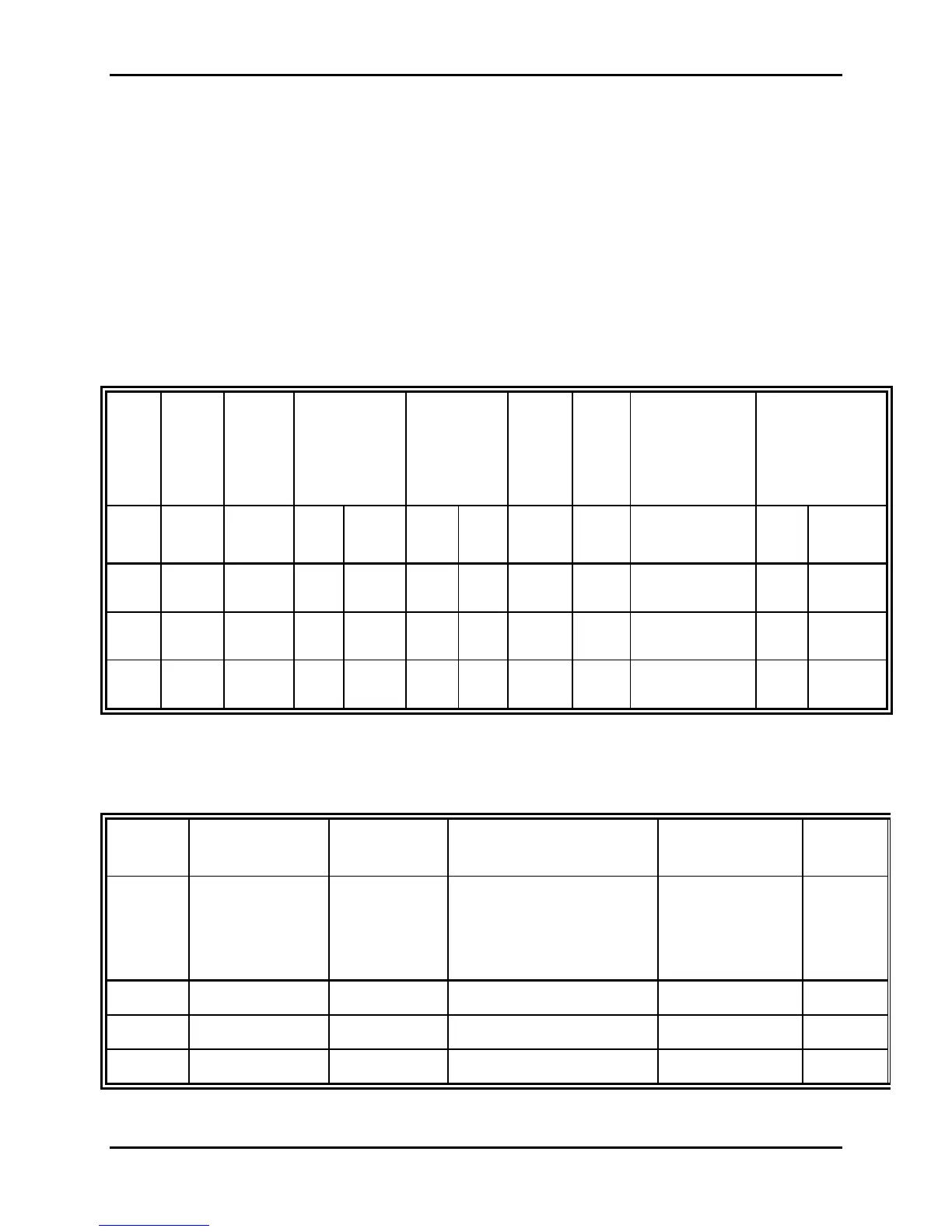

DAILY OPERATION LOG

Date Film

Thick-

ness

Load

Size

Sq.

Inches

Dimer Usage Base

Pressure

Base

Pump

Down

Time

Run

Time

Vaporizer

Parameters

Chamber

Parameters

Run Total Cold Hot Set Point SP Lo

(Base)

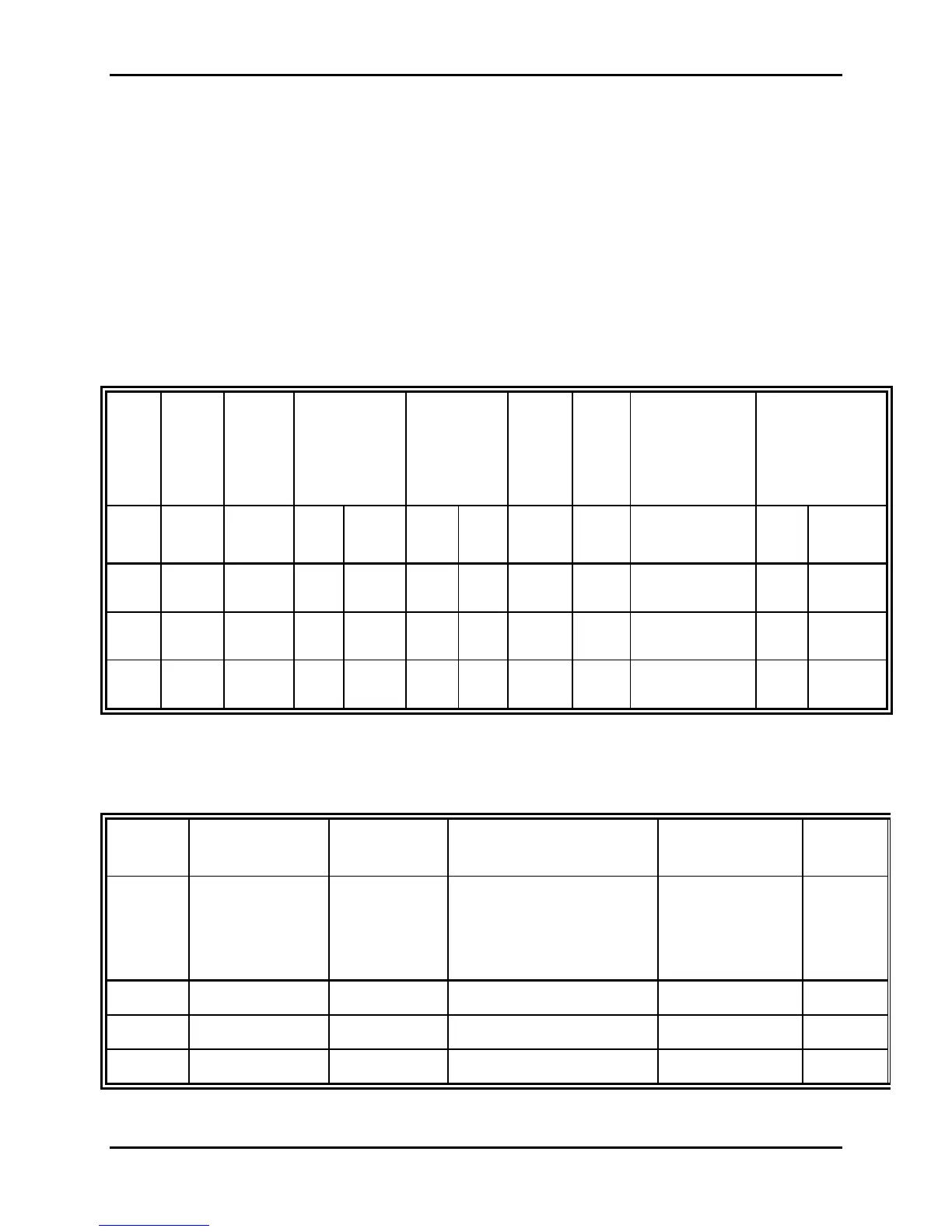

DAILY MAINTENANCE LOG

(Inspect, Check Condition, Remove, Replace, Clean or Apply)

Date O-Rings and

Sealing Surfaces

Vaporizer and

Dimer Boat

Chamber, Baffle Turntable,

Sight Glass

Cold Trap and

Probe

Vacuum

Pump Oil

Load Door

Chamber Gasket

Cold Trap

Remove

Residuals

Remove Parylene Build-up

Apply Release Agent on

Bare Surfaces Only

Thoroughly Clean

After Every Run

Apply Release

Agent

Check

Replace

Loading...

Loading...