3 SYSTEM DESCRIPTION

8026364 / V1-0/2022-03|SICK

SUPPLEMENTARY OPERATING INSTRUCTIONS | VMS4200/5200

Subject to change without notice

3.3.3 Recording of measured values and data processing

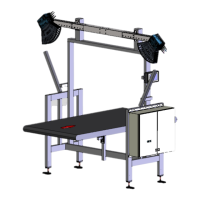

Fig. 12: Measuring point determination of the VMS4200/5200

• The calculation of measurement values begins as soon as an object is transported past

the 2D LiDAR sensors on the equipment below.

• The two 2D LiDAR sensors span a two-dimensional measuring range and perform a

non-contact scan of the surface of the object on the cross belt conveying equipment.

• They cyclically transmit the detected measuring points to the SIM2000-2 Prime

controller for further processing.

Fig. 13: Building 3D model in the SIM2000-2 Prime controller

• When the detected conveyor belt speed and the specific position of the object on the

belt are factored in, a spatial model is created.

• The SIM200-2 Prime controller calculates the length, width and height of the smallest

rectangular box that fully encloses the object. These dimension values can be used to

calculate the volume of the rectangle.

Loading...

Loading...