19/44

GENIUS 2.2, Electromechanical mul-point lock

19/4402.2020H39.ELEKS013EN-00

5

Local building laws and regulaons must be observed

before and during door installaon in addion to the

following requirements and condions:

• Before installing the mul-point lock, check the di-

mensional accuracy of the door and the door frame.

The mul-point lock must not be installed if the

door or the frame is warped or damaged.

• Surface treatment of the door and door frame must

take place before the mul-point lock is installed.

Subsequent surface treatment can reduce the func-

onal capacity of the mul-point lock.

• Observe the specied posions and sizes for all

milling and drilling dimensions within the dened

tolerances. Observe the horizontal and vercal ad-

justment accurately.

• Remove any splinters from routed pockets aer

milling.

• Do not overghten the screws or insert them at an

angle.

• Once the mul-point lock is installed, do not per-

form mechanical work on the door (such as drilling

or milling).

• Do not drill into or through the main lock under any

circumstances.

• Install hardware components and cylinder ush.

Adhere to airgap (interval between faceplate and

frame parts): the mul-point lock funcons safely

with an airgap between 3.5 mm +/- 1.5 mm. Beyond

this, the fabricator must ensure that the airgap is

large enough to guarantee the freedom from con-

straint of the door.

• Avoid corrosion damage to components or to the

door by using non-acidic, moistening sealants.

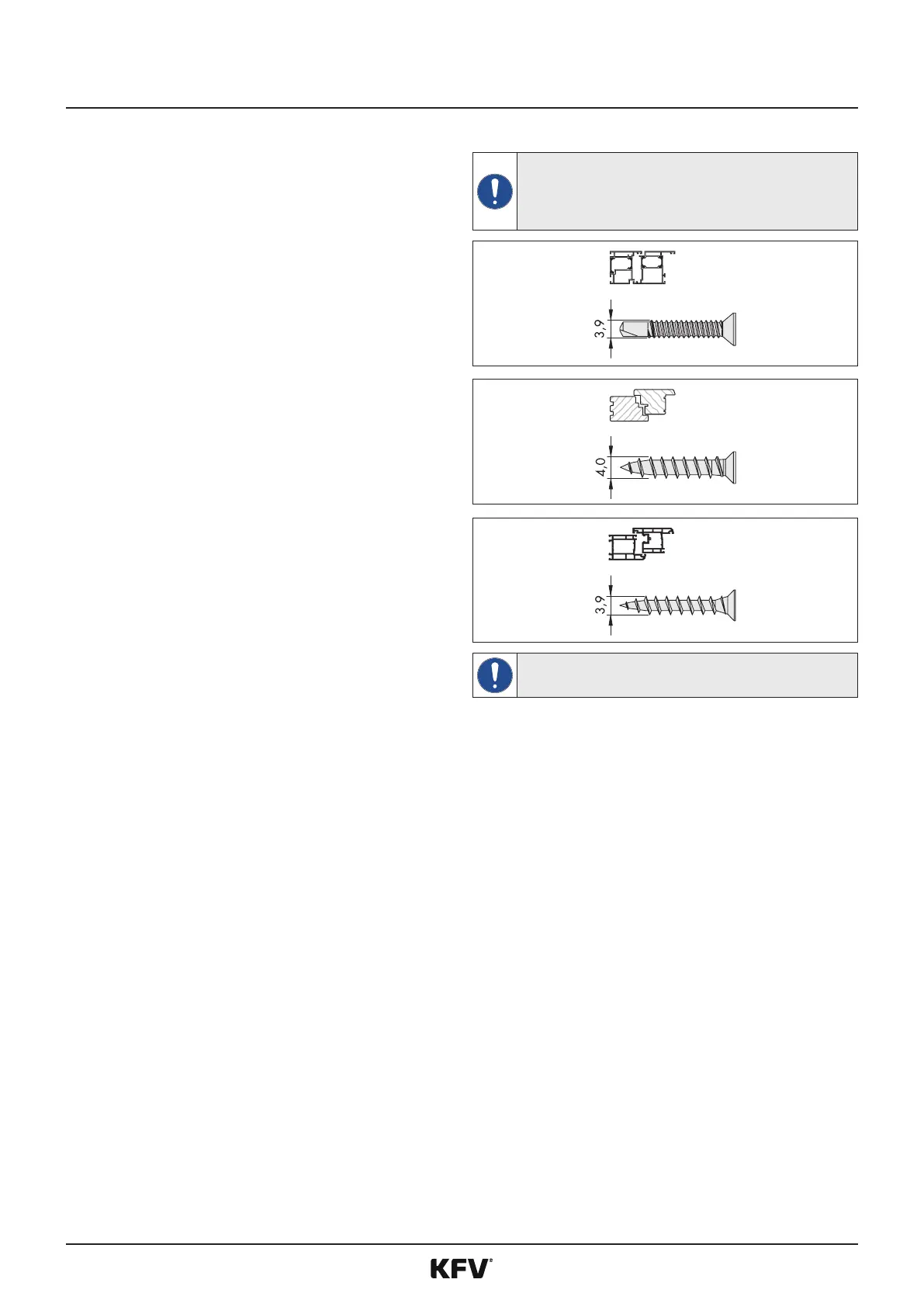

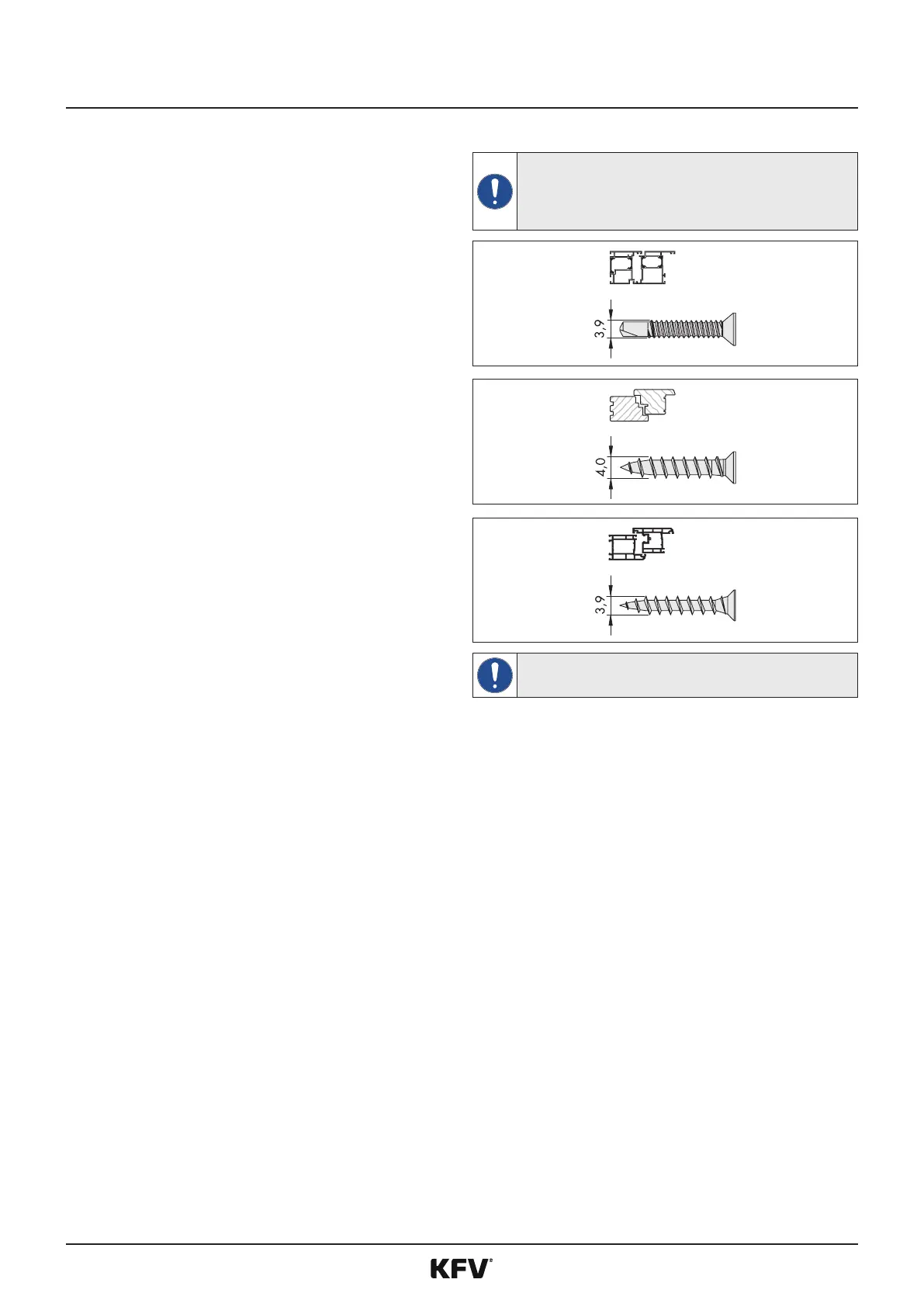

For the assembly, choose the screw lengths and screw heads

to ensure that an adequate intervenon in the material and

ushness with the faceplate of the mul-point lock and the frame

parts are ensured. For the screw dimension, we recommend the

following screws:

Adhere to the screw torque specied by the producer!

Loading...

Loading...