6

Fault rectification

Hardware diagnostics

54

Siemens AG CM2G5111en

2014-05-16

Preliminary tests

Check/Test Description OK

Switch off the power supply

Ensure that the drive is disconnected from the line supply.

Securing

Secure the drive so that it cannot be switched on again.

Ensure that there is no voltage present at

the drive.

Measure the voltage between L1/L2 and L3.

Make sure that the system is completely de-energized.

Damage caused by external factors

Check whether parts are damaged, for example by corrosion, paint,

moisture, oil, dust, powder etc.

Electrical damage

Look for evidence of flashovers or burning at the power terminals.

These are caused by connecting the power cables incorrectly.

Interference by customers

Examine the drive for signs that customers have attempted to repair

the drive themselves.

Fuses

Check the sizes of the fuses.

Make sure that they are not "open".

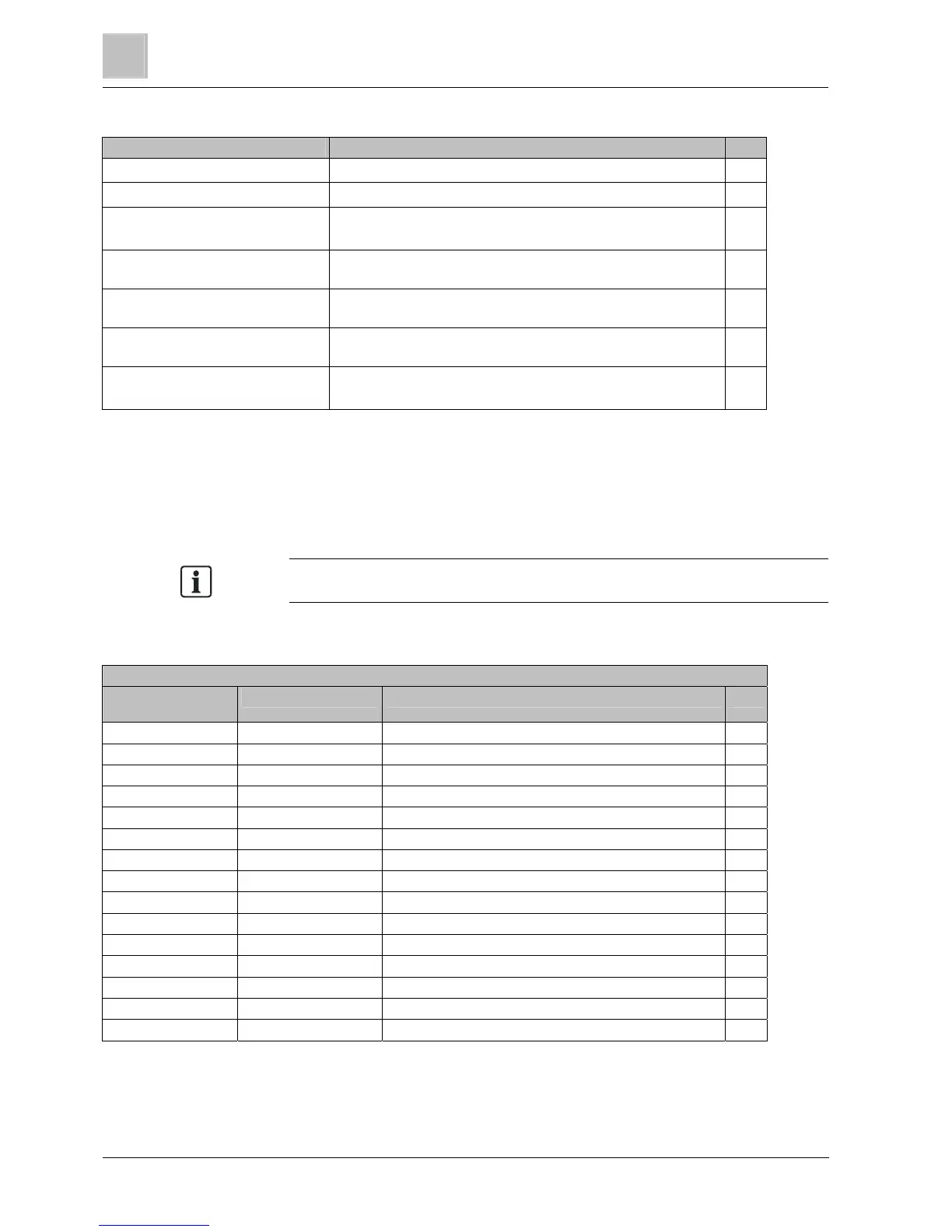

Static check on the drive

The following checks are standard tests. These tests can be performed on most

drives which are designed in accordance with the conventional principle "Rectifier –

DC bus – IGBT bridge". The customer is not meant to use the DC bus terminals on

the PM230/G120P. However, the terminals are accessible on some models.

Set the multimeter to "Diode" in order to measure the terminals.

The following tables show where to connect the test cable on the drive and what

test result you are likely to receive.

Rectifier tests

Positive measuring

point

Negative measuring point Expected result OK

L1 DC+ Diode aperture – typically 0.3 – 0.5V

L2 DC+ Diode aperture – typically 0.3 – 0.5V

L3 DC+ Diode aperture – typically 0.3 – 0.5V

L1 DC Diode block – OL/High impedance

L2 DC Diode block – OL/High impedance

L3 DC Diode block – OL/High impedance

DC+ L1 Diode block – OL/High impedance

DC+ L2 Diode block – OL/High impedance

DC+ L3 Diode block – OL/High impedance

DC L1 Diode aperture – typically 0.3...0.5 V

DC L2 Diode aperture – typically 0.3...0.5 V

DC L3 Diode aperture – typically 0.3...0.5 V

Loading...

Loading...