Mechanical mounting

6.3 Installing/removing the rotor

SIMOTICS M-1FE2 built-in motors

Hardware Installation Manual, 04/2020, A5E50074509B AA

93

Personal protection equipment

● Face protection shield

● Gloves for protection against cold or heat depending on the joining process

● Sealed protective clothing for protection against any oil leaks and high or low surface

temperatures

Devices for joining the rotor

The following devices may be required depending on the joining process.

Joining with the heat process (shrink fit)

Joining with the cold process (stretch fit)

• Hot-air oven with temperature monitoring - suitable for

installation temperatures

1)

• Oven volume appropriate for the rotor type, placement of

the oven in the immediate vicinity of the workplace

• Air-conditioned room or cold chamber for tempering the

spindle shaft and rotor core

• Dewar vessel with liquid nitrogen N2 (-195.8 °C)

• For a small workspace: good ventilation

1) The temperatures for the installation can be found in the "Installation temperatures" Cable

in chapter "Mounting the rotor (Page 98)".

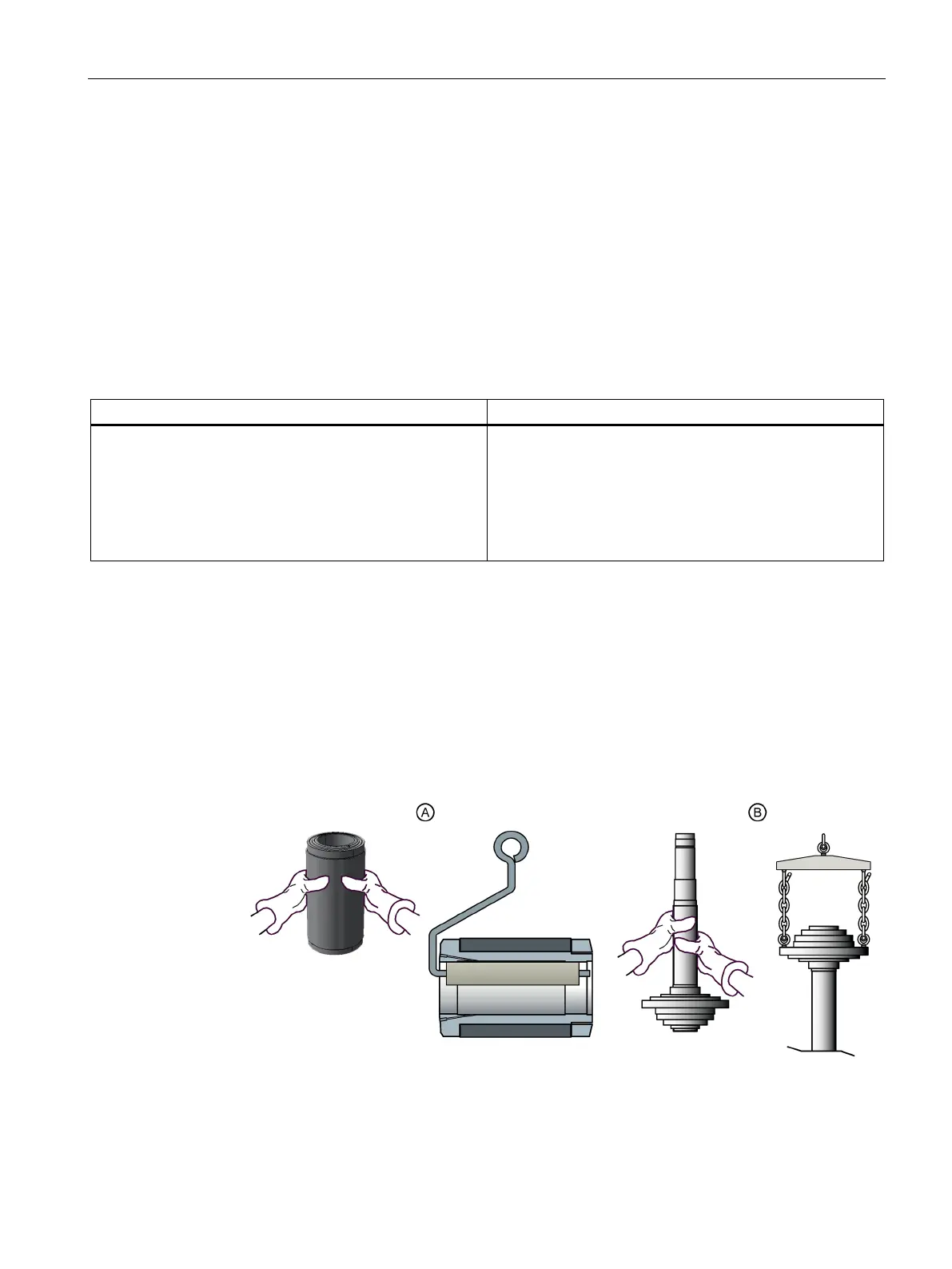

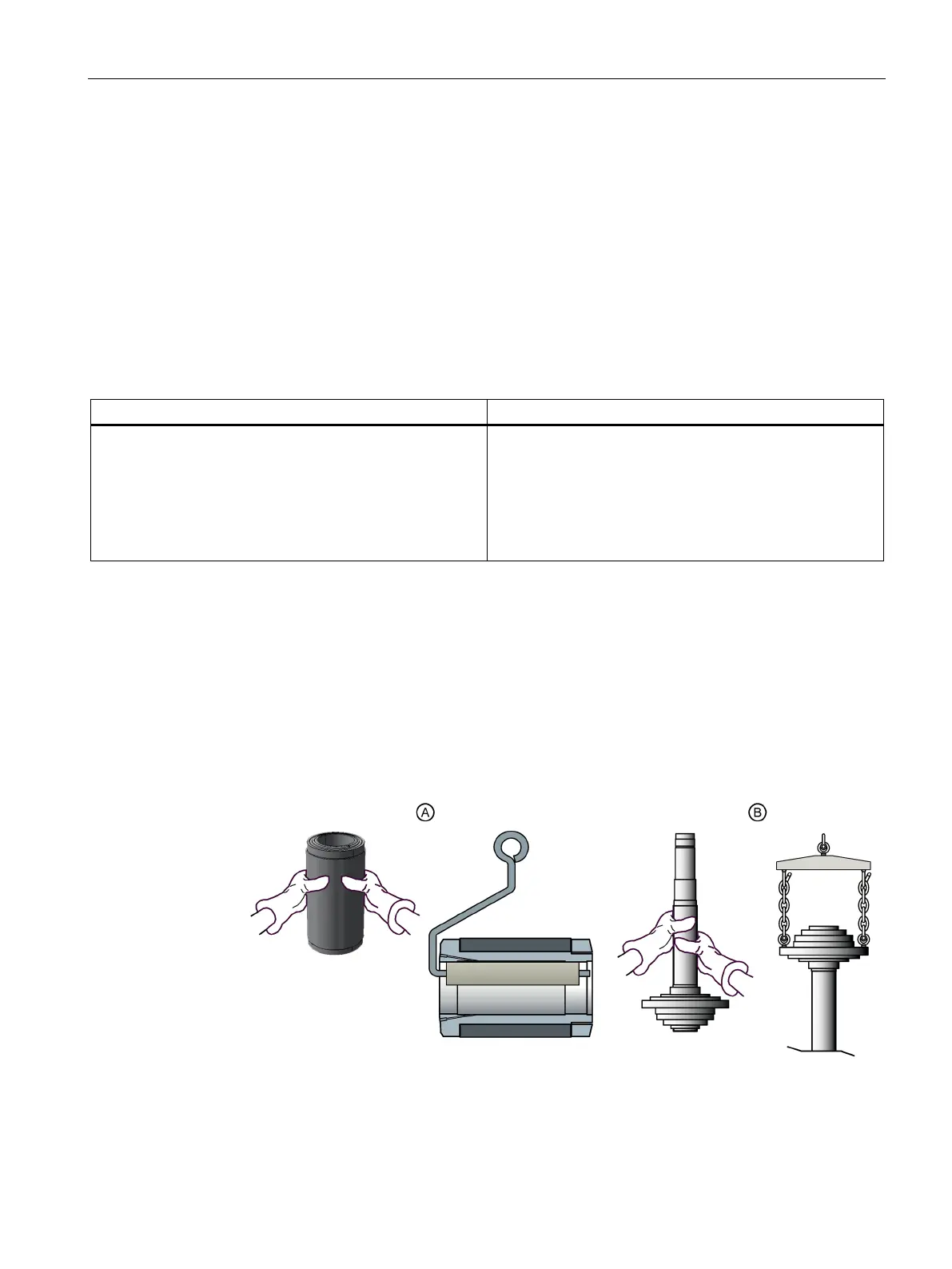

Hoisting gear for transporting the components

Hoisting gear, gripper, load suspension device, see figure "Examples for transporting

components"

● Carrying capacity dependent upon the rotor core weight (please refer to the rating plate

for the weights)

● Preferably with a device for quick lowering

Transport of the heated rotor core

depending on size and weight

Transport of the cooled or tempered spindle shaft

depending on size and weight

Figure 6-3 Examples for transporting components

Loading...

Loading...