2

10.04 Operation

2.13 Tools and tool offsets

2

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 2-149

Tool radius

compensation

The contour and tool path are not identical. The cutter or tool nose

radius center must travel along a path that is equidistant from the

contour.

For this purpose, the programmed tool center point path is

automatically displaced by the control – as a function of radius and

machining direction – in such a way that the tool edge travels exactly

along the programmed contour.

The tool radius must be entered in the tool list. The control fetches the

required radii during program execution and calculates the tool path

from these values.

Equidistant

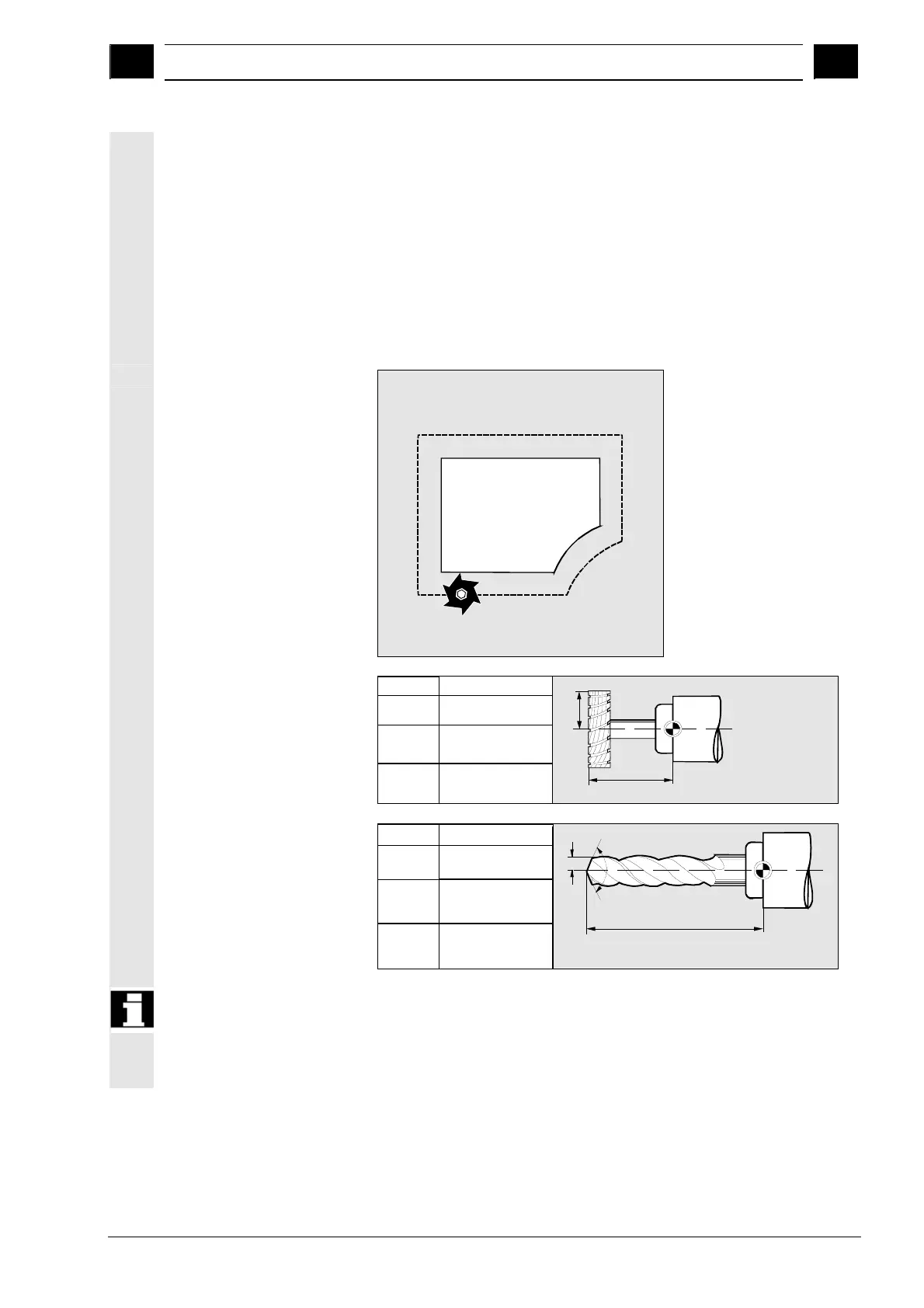

Offset values

milling tool (example)

F

Z

Length in Z

Radius in X/Y

Y

Length in Y

Radius in Z/X

Length in X

Radius in Y/Z

X

F - Toolholder

reference point

Radius

Length

Infeed

Geometry in plane

Offset values

drill (example)

Z

Length in Z

Y

Length in Y

Length in X

X

F - Toolholder reference point

Infeed

Geometry in plane

F

Length

F

Angle

Radius

Offset values are used in the simulation display and programming

graphic for the following tools:

• Drill: Angle and radius/diameter

• Centering tool: Radius/diameter

Loading...

Loading...