3

10.04 Programming with ShopMill

3.1 Basics of

ro

rammin

3

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 3-173

Traversing at rapid

traverse

The programmed path is traversed along a straight line at the fastest

possible velocity without the workpiece being machined. Rapid

traverse is a non-modal command, i.e. if you want the axis to traverse

rapidly in the next block, then you must enter "Rapid traverse" as

feedrate (F) again.

If you do not program a feedrate or rapid traverse, the axis is

automatically traversed at the last programmed feed value (machining

feedrate).

Traversing at feedrate

(machining feedrate)

The tool travels at the programmed feedrate F along a straight line or

on a circle to the programmed end point and then machines the

workpiece. Machining feedrates (F) are specified in mm/min, mm/rev

or mm/tooth. The feedrate for milling cycles is automatically converted

on switchover from mm/min to mm/rev and vice versa.

With milling cycles, the feedrate for rough cutting is relative to the

milling tool center point. This also applies to finish cutting, with the

exception of concave curves where the feedrate is relative to the

cutting edge (contact point between milling tool and workpiece).

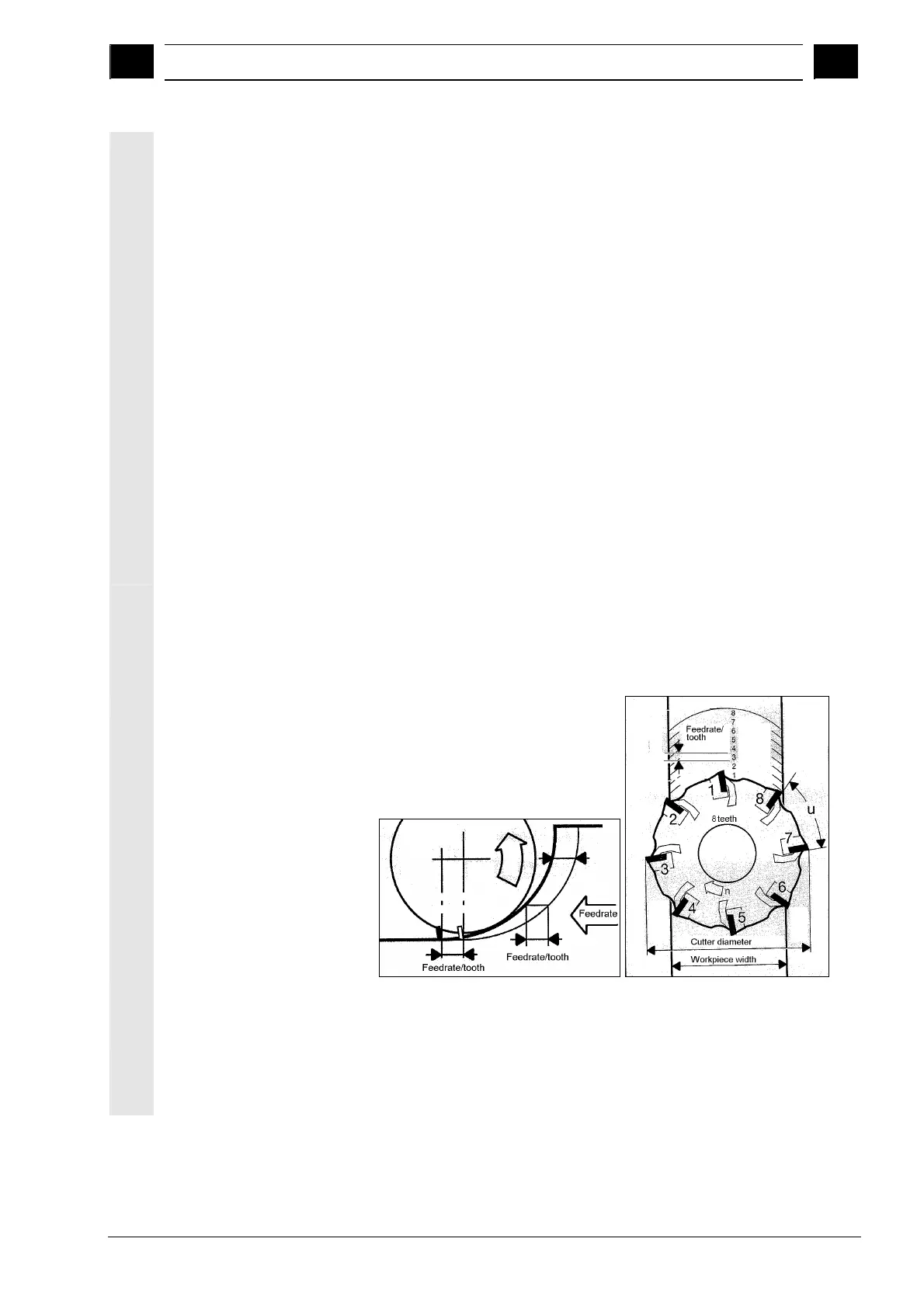

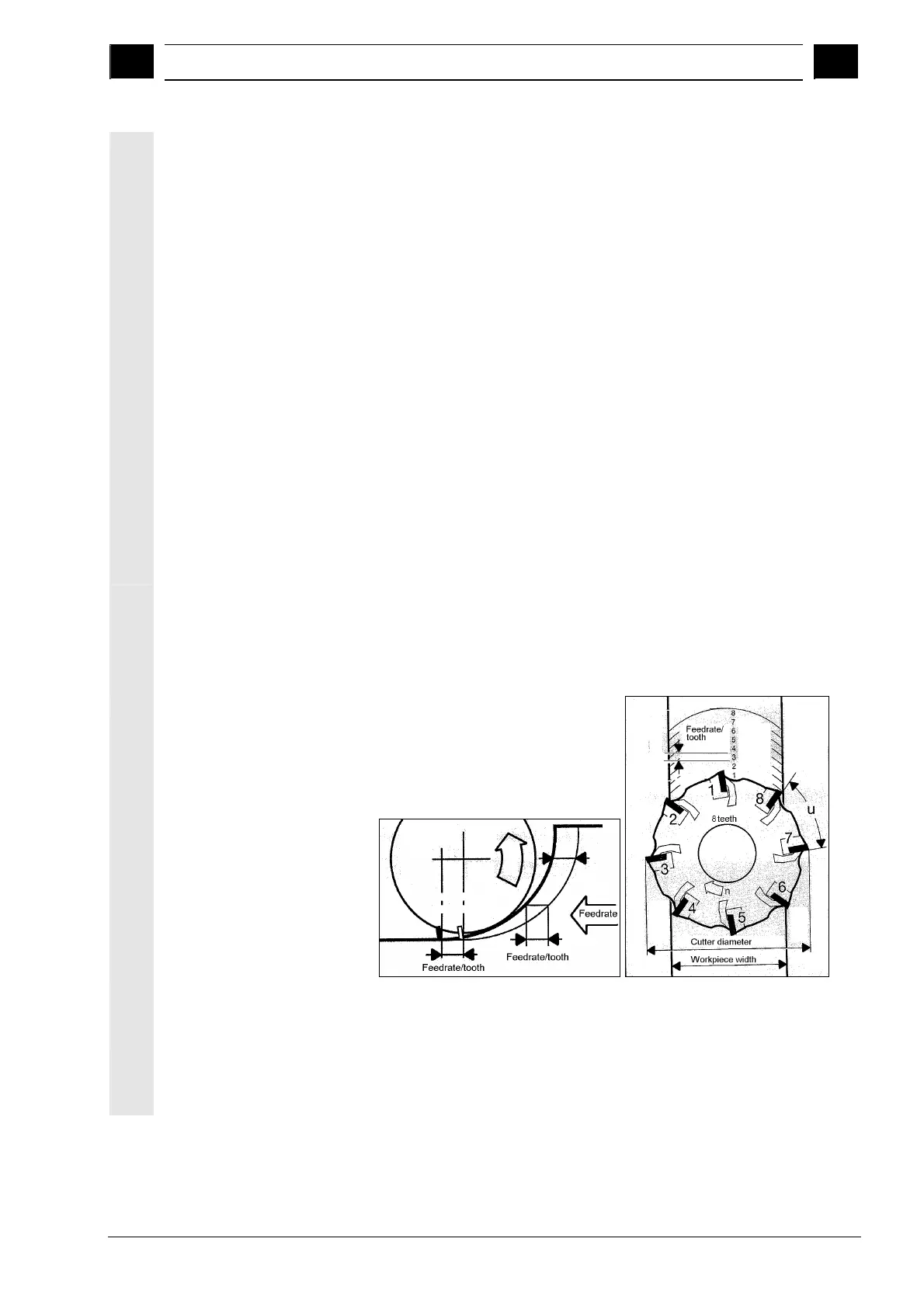

Feedrate in mm/tooth

Mills are multi-edged tools. For this reason, a value must be found

which guarantees that each cutting edge can machine the workpiece

under the best possible conditions. Feed per tooth corresponds to the

linear path traversed by the mill when a tooth is engaged. Feed per

tooth is also the effective distance covered by the table feed between

the engagement of two successive cutting edges.

Feedrate in mm/tooth

The machining feedrate is modal, i.e. even if the machining process

changes, you need not enter a new feedrate if the feedrate

programmed in the preceding block is still appropriate. This applies

even if you have programmed a rapid traverse command in between.

Loading...

Loading...