Components

For operation, programming, and visualization purposes, the corresponding operating software

is already integrated into the CNC software for the NCU and therefore runs on the high-

performance NCU multi-processor module. The SINUMERIK PCU (e.g. SIMATIC IPC for

SINUMERIK) can be used for increased performance in the operating area.

Up to four distributed OPs can be operated on one NCU/IPC. The operator panel can be installed

as a thin client at a distance of up to 100 m.

The following components can be connected to the NCU:

• SINUMERIK operator panel front with TCU x 0.3/IPC and Machine Control Panel/Machine Push

Button Panel

• SIMATIC Thin Client (from rmware V2.0.1)

• SIMATIC CE panel

• SINUMERIK handheld units

• Distributed PLC I/O

– via PROFIBUS DP:

e.g. SINUMERIK I/O modules PP 72/48D and Analog Drive Interface for 4 axes ADI 4

– via PROFINET IO:

SINUMERIK I/O modules PP 72/48D PN and PP 72/48D 2/2A PN

• SINAMICS 120 drive system

• Feed and main spindle motors

– Synchronous motors 1FT / 1FK / 1FE1 / 2SP1

– 1PH / 1PM induction motors

– Linear / torque motors 1FN / 1FW6

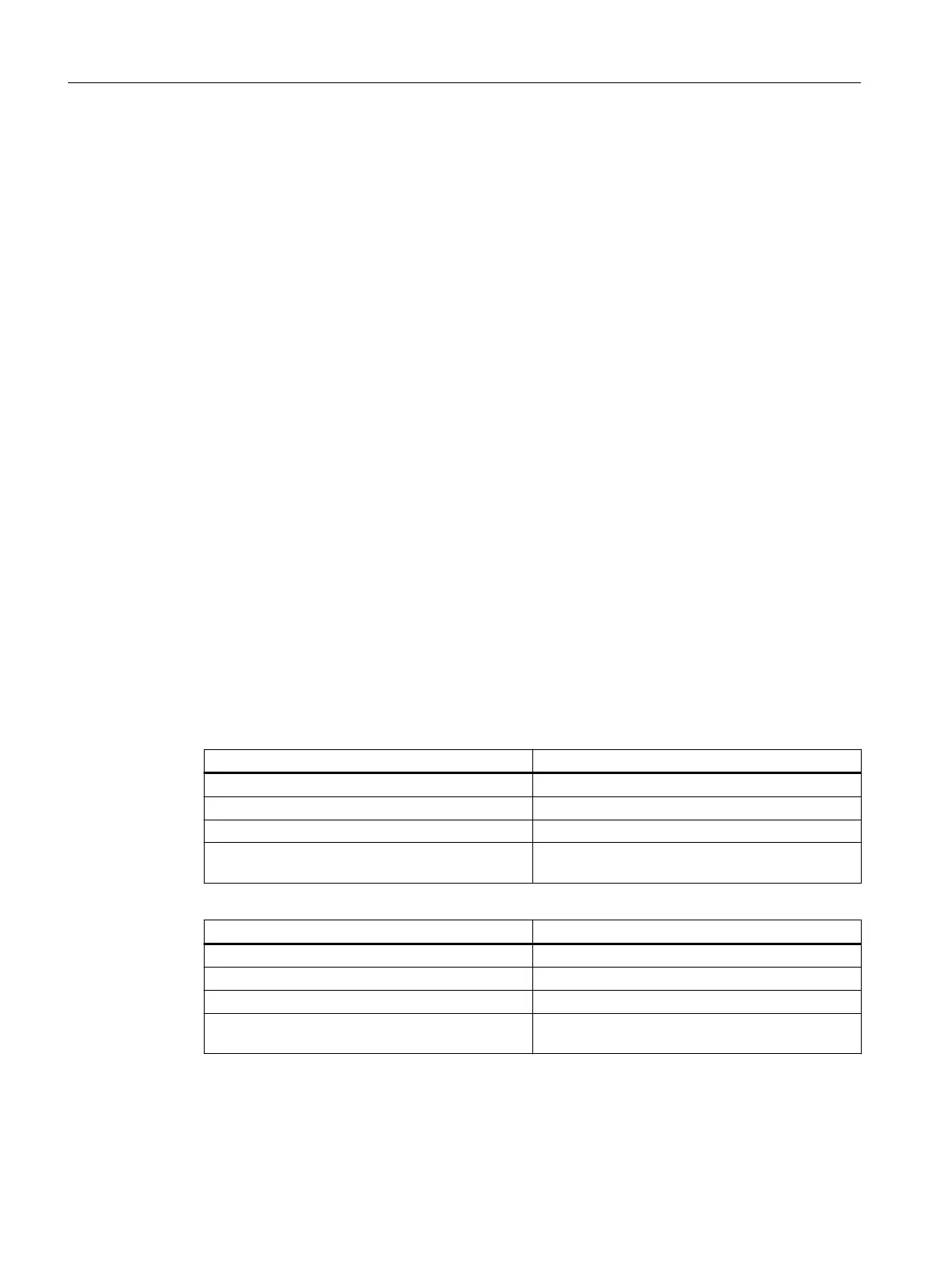

PROFIBUS

PROFIBUS I/O for the PLC/ NCK I/O (isochronous) x

NCK / PLC isochronous drives (e.g. ADI 4, CU320) x

PROFIsafe V2 at both interfaces x

Second DP/MPI isochronous interface available for

NCK

x

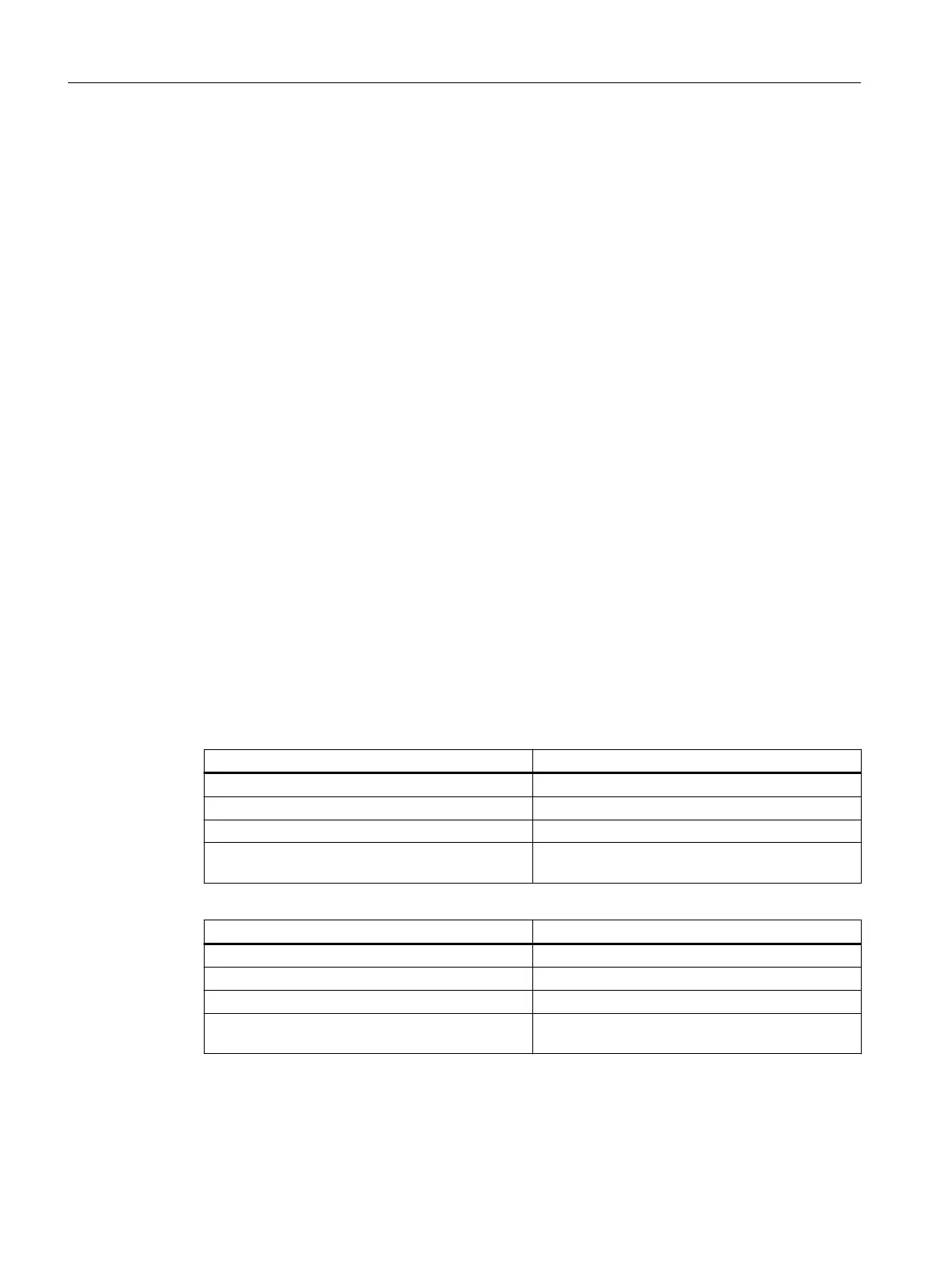

PROFINET

PROFINET I/O for PLC peripherals x

PROFINET I/O for NCK peripherals (isochronous) x

PLC isochronous drives x

NCK isochronous drives (also with Safety Integra‐

ted)

x

1)

System overview

2.2 System conguration

NCU 7x0.3B PN

18 Equipment Manual, 10/2020, 6FC5397-1EP40-6BA1

Loading...

Loading...