6 Assi

nin

Parameters to the Control and the PLC Pro

ram

6

03.96

6.9 Axes and spindles

6-131

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

Note

Axes which interpolate with one another must have the same following error at

a given velocity. This can be achieved by setting the same K

V

factor or through

dynamic response matching via

MD 32900: DYN_MATCH_ENABLE and

MD 32910: DYN_MATCH_TIME.

References: /FB/, G2, “Velocities, Actual Value Systems, Cycle Times”

If a K

V

factor is already known for the machine in question, this can be set and

checked. To check the factor, the axis acceleration must be reduced via

MD 32300: MAX_AX_ACCEL in order to ensure that the drive does not reach

its current limit during acceleration and braking.

The K

V

factor must also be checked for high speeds of the rotary axis and

spindle (e.g. for spindle positioning, tapping).

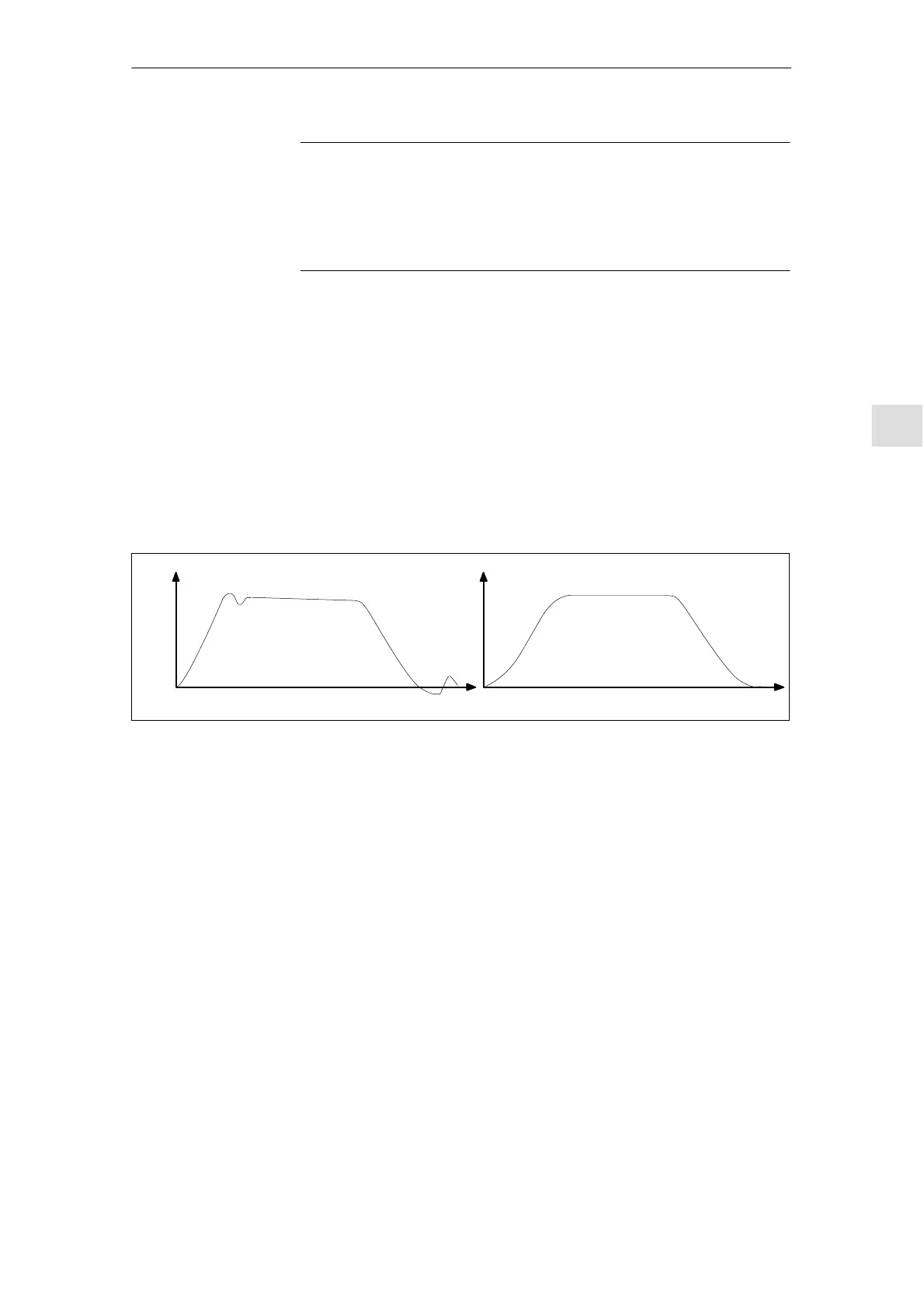

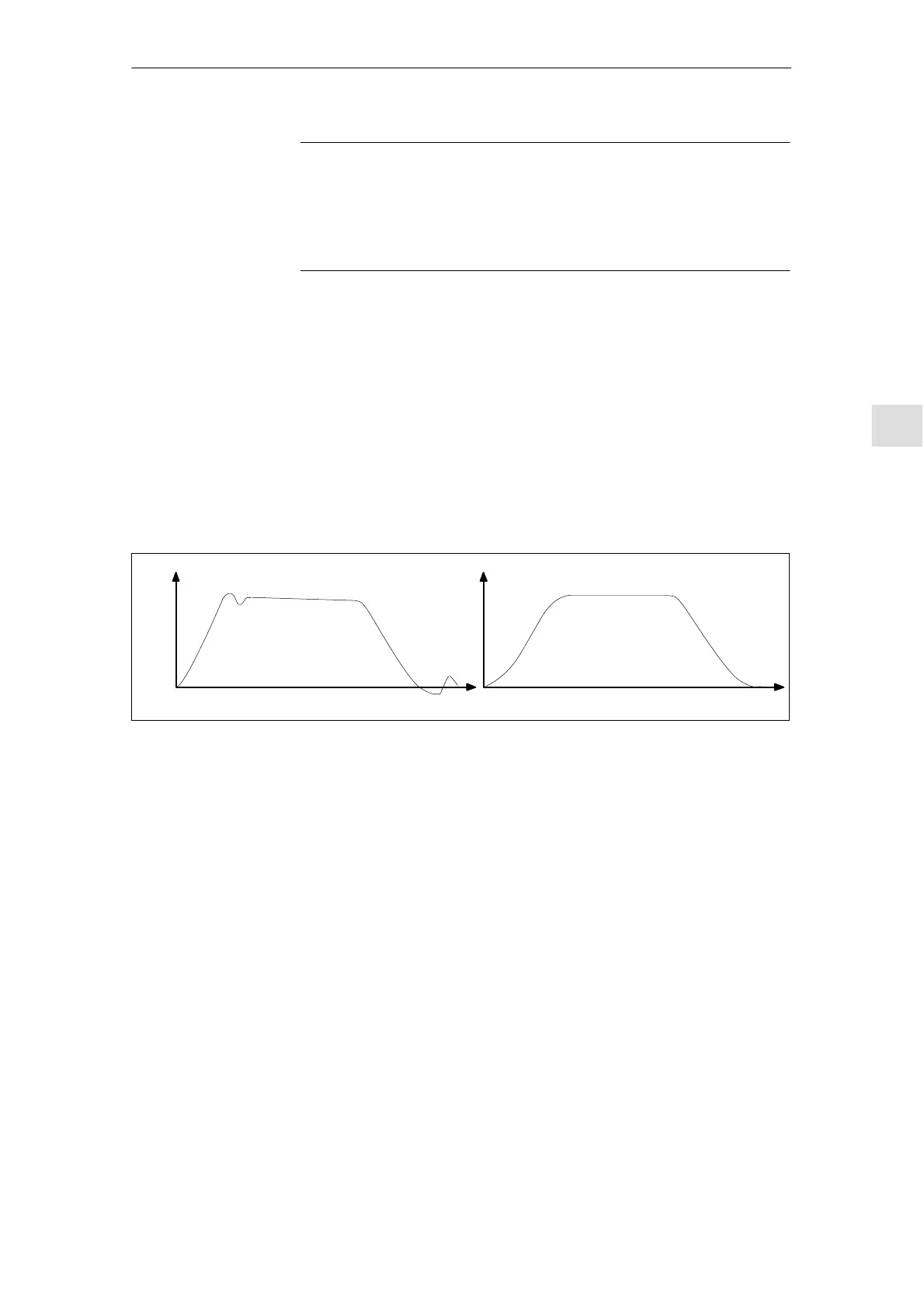

The approach behavior at various speeds can be checked by means of a

storage oscilloscope or the SIMODRIVE 611D start-up software. The speed

setpoint is recorded for this purpose.

n

set

[V]

t [ms]

n

set

[V]

t [ms]

“Badly”“Well”

selected K

V

factor

selected K

V

factor

Fig. 6-17 Speed setpoint characteristic

No overshoots may occur while the drive is approaching the static statuses; this

applies to all speed ranges.

The SIMODRIVE 611D start-up software offers various methods of checking the

K

V

factor (e.g. frequency measurement, speed and position control loop mea-

surement).

S Acceleration too high (current limit is reached)

S Error in speed controller (re-optimization necessary)

S Mechanical backlash

S Mechanical components canted

For safety reasons set the K

V

factor to a little less than the maximum possible

value. Static checking of the K

V

factor is performed with the “Service Axis”

softkey in the “Service Display” menu. The real K

V

factor must precisely match

that set because monitoring functions are derived from the K

V

factor that would

otherwise respond (e.g. contour monitoring).

Checking the

loop gain

Causes of

overshoots in

position control loop

Loading...

Loading...