6 Assi

nin

Parameters to the Control and the PLC Pro

ram

6

03.96

6.9 Axes and spindles

6-132

Siemens AG 2000 All Rights Reserved

SINUMERIK 840D Installation and Start-Up Guide (IAD) – 04.00 Edition

The axes are accelerated and braked at the acceleration value entered in MD

32300: MAX_AX_ACCEL. This value should allow the axes to be accelerated

and positioned rapidly and accurately while ensuring that the machine is not

unduly loaded. The acceleration default settings are in the 0.5 m/s

2

to 2 m/s

2

range.

The acceleration data entered can be either empirical values or the maximum

permissible acceleration values which the user must calculate. The data must

always be checked after entry for which the SIMODRIVE 611D start-up software

and an oscilloscope are required.

MD 32300: MAX_AX_ACCEL

Overshoot-free acceleration and approach with rapid traverse velocity under

maximum load (heavy workpiece).

Via analog outputs (Section 10) or

start-up software for SIMODRIVE 611D

After the acceleration has been entered, the axis is traversed rapidly and the

actual current values and current setpoint are recorded. This recording shows

whether the drive reaches the current limit. While traversing rapidly, the drive

may reach the current limit briefly. However, the current must be well below the

current limit before the rapid traverse velocity or the final position is reached.

Slight load changes during machining must not cause the current limit to be

reached. Excessive current during machining causes falsification of the contour.

It is therefore advisable in this case as well to enter a slightly lower acceleration

value in the MD than the maximum permissible value. Axes can be assigned

different acceleration values even if they do interpolate with one another.

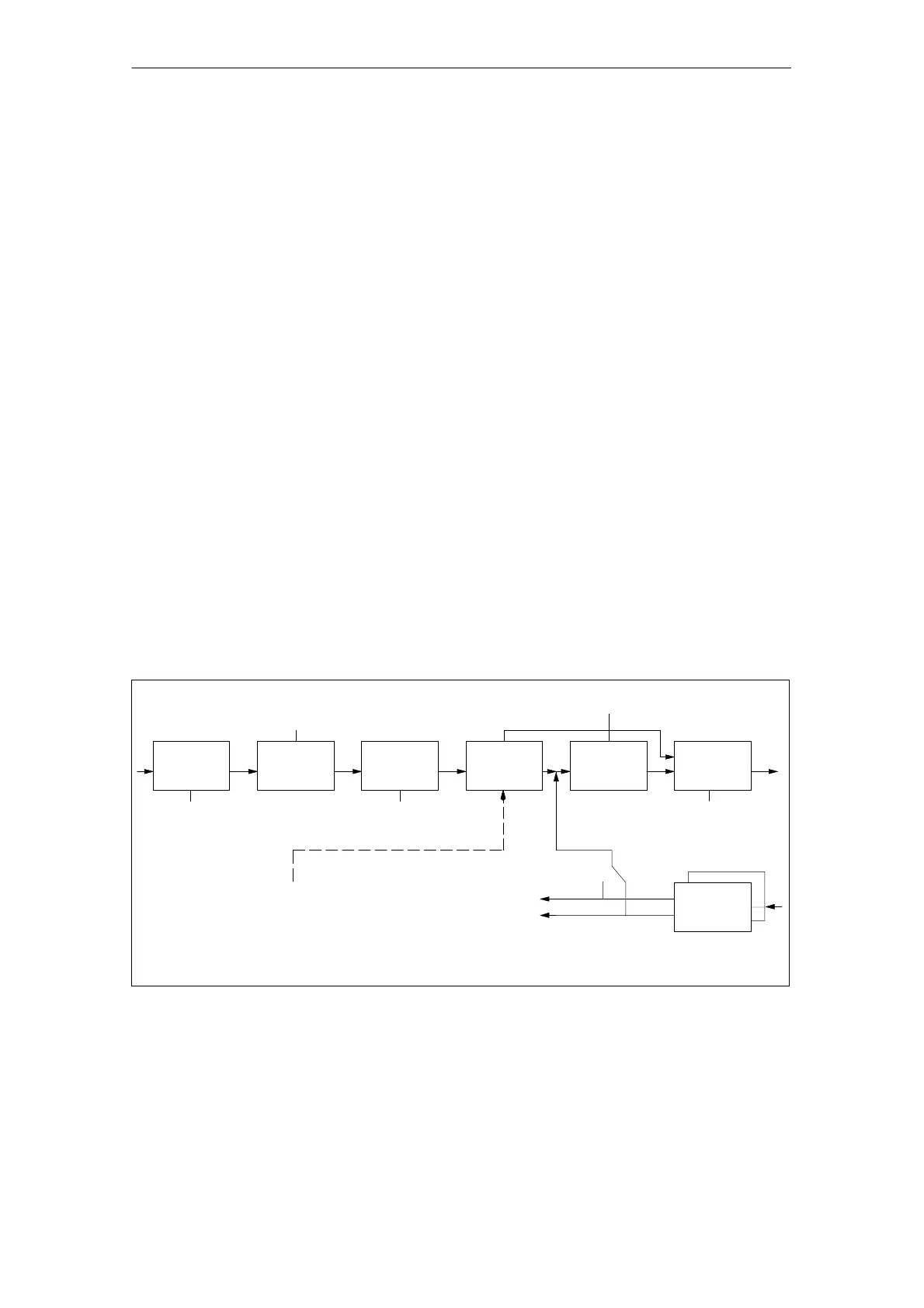

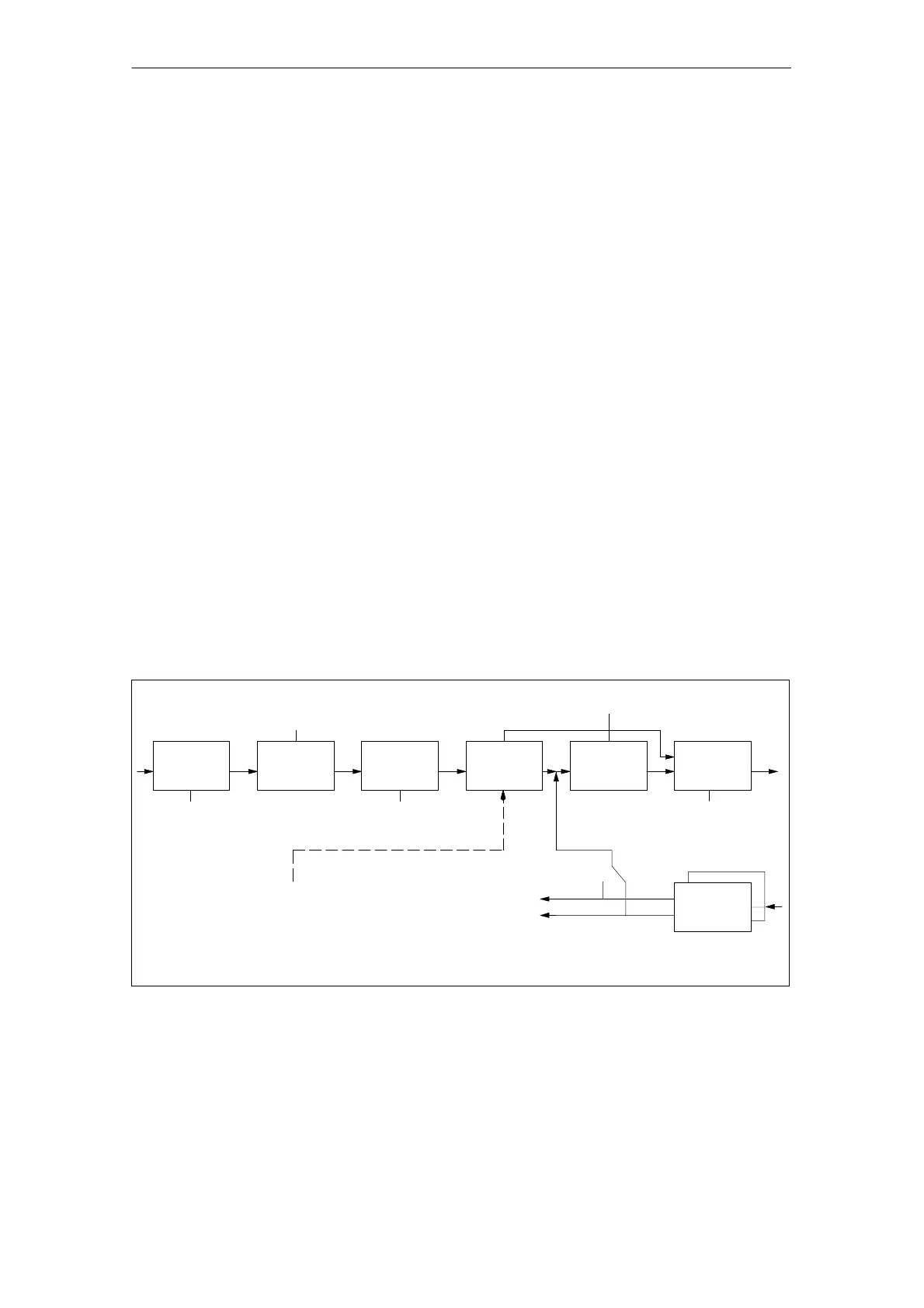

Fine

inter–

polation

Jerk

limitation

Dynamic

Feedforward

control

Speed

setpoint

processing

Actual value

processing

tung

IS position

meas.

system 1/2

MD32400 AX_JERK_ENABLE

MD32410 AX_JERK_TIME

MD32200 POSCTRL_GAIN

MD33000

FIPO_TYPE

MD32900 DYN_MATCH_ENABLE

MD32910 DYN_MATCH_TIME

MD32620 FFW_MODE

MD32630 FFW_ACTIVATION_MODE

MD32610 VELO_FFW_WEIGHT

MD32650 AX_INERTIA

MD32810 EQUIV_SPEEDCTRL_TIME

MD32800 EQUIV_CURRCTRL_TIME

MD32100 AX_MOTION_DIR

MD32500 FRICT_COMP_ENABLE

MD32110 ENC_FEEDBACK_POL

MD32700 ENC_COMP_ENABLE

MD32450 BACKLASH

response

matching

Closed loop

control

Fig. 6-18 Additional parameters for position control

Acceleration

Checking and

calculating

acceleration

values

Setting

Identification

Measurement

Loading...

Loading...