Parameterizing Steps 05.2006

6SE7087-2JD60 Siemens AG

9-64 Operating Instructions SIMOVERT MASTERDRIVES

In exceptional cases this is not necessary:

♦ If P068 is only adjusted between 0 and 2 (dv/dt filter).

♦ If P340 is adjusted in integer increments, e.g. from 2.5 kHz to

5.0 kHz...7.5 kHz... etc.

♦ If P339 is not set to over-modulated space vector modulation; if

P339 = 4, 5 (over-modulated space vector modulation), the

overrange limit P342 must also be reduced to limit torque ripple and

motor heating.

♦ If changeover is made between speed and torque control

(P100 = 4, 5).

♦ If changeover is made between speed and frequency control and

the following parameters are adapted:

f-control (P100 = 3) n-control (P100 = 4)

P315 = EMF Reg.Kp 2 x Kp Kp

P223 = Smooth.n/f(act)

≥ 0 ms ≥ 4 ms

P216 = Smooth. n/f(pre)

≥ 4.8 ms ≥ 0.0 ms

P222 = Src n/f(act) KK0000 KK0000 (KK0091)

The speed controller dynamic response may have to be reduced in the

case of encoder-less speed control (frequency control) (Reduce gain

(P235); increase Tn (P240)).

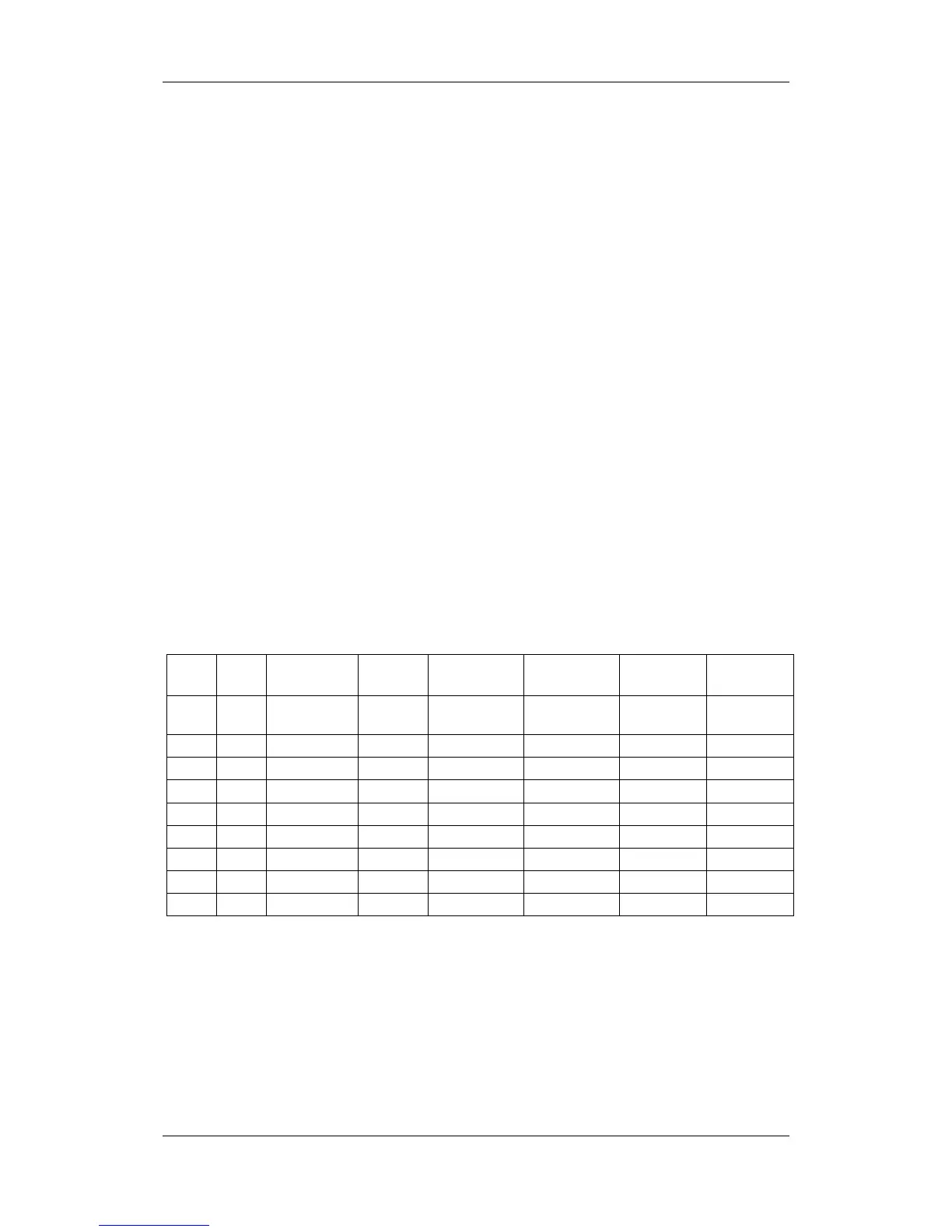

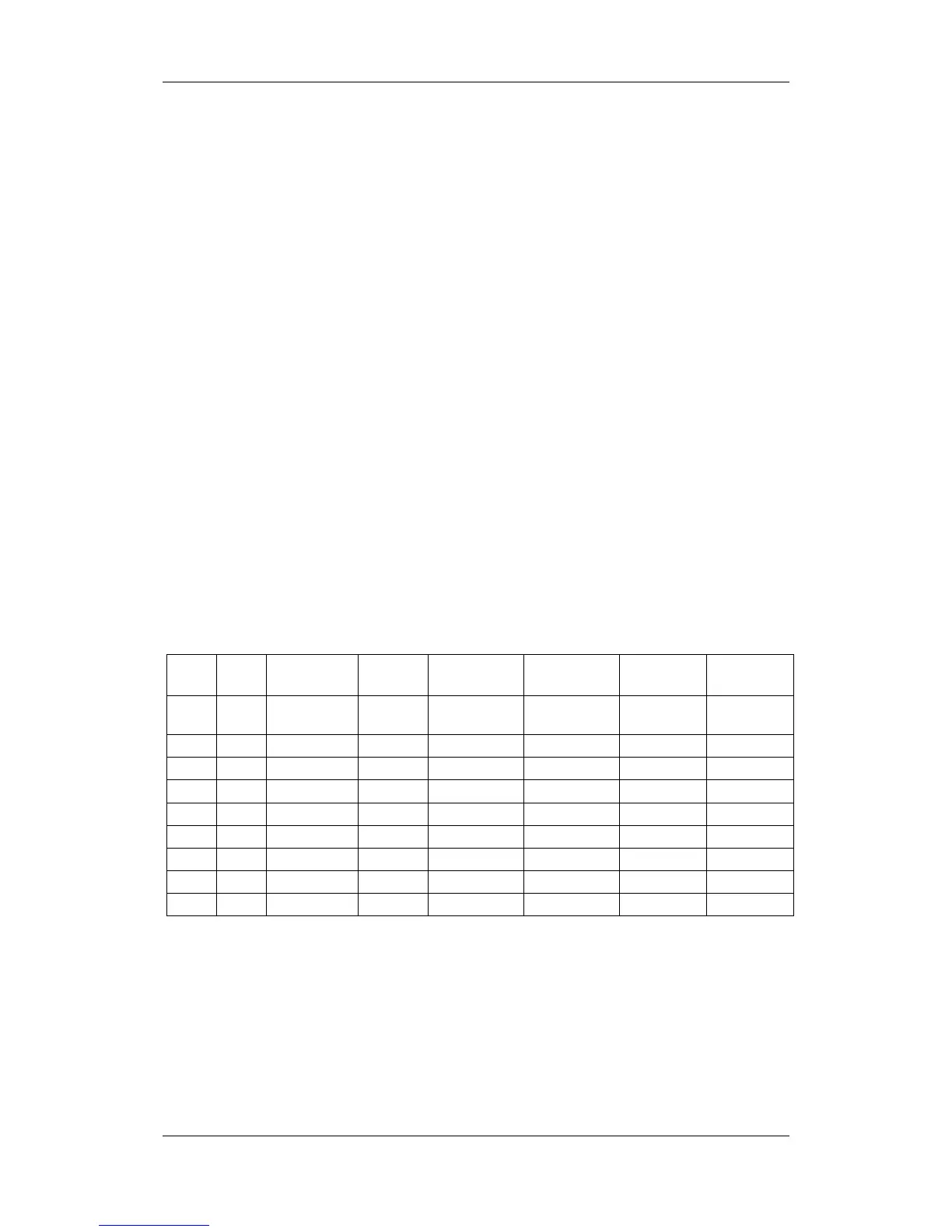

Activation of the measured value or PTC thermistor monitoring for the

motor causes different fault and alarm signals depending on the setting

of parameters P380 and P381. These are listed in the following table:

P380 /

°C

P381 /

°C

Sensor r009 Alarm A23 in

ready

Alarm A23 in

operation

Fault F20 in

ready

Fault F20 in

operation

= 0 = 0

KTY84 for RL

adapt.

if P386 =

2

- - - -

= 0 = 1 PTC no - - - yes

1)

= 1 = 0 PTC no yes

1)

yes

1)

- -

= 1 = 1 PTC no yes

1)

- - yes

1)

= 0 > 1 KTY84 yes - - - yes

3)

> 1 = 0 KTY84 yes yes

3)

yes

3)

yes

4)

yes

2)

> 1 > 1 KTY84 yes yes

3)

yes

3)

yes

4)

yes

3)

= 1 > 1 KTY84 no yes

1)

- - yes

3) 2)

> 1 = 1 KTY84 no yes

3)

yes

3)

yes

4)

yes

2)

1) Alarm or fault are triggered on violation of the PTC thermistor temperature or on a

cable break (not a cable short circuit).

2) Fault is only triggered on cable break or cable short-circuit.

3) Fault or alarm on violation of the temperature limit..

4) Fault is only triggered on cable short-circuit.

Temperature

monitoring of the

motor

Loading...

Loading...