80

EN

8.3.2 Cleaning the burner

The burner does not require any particular maintenance simply

dust it with a soft brush.

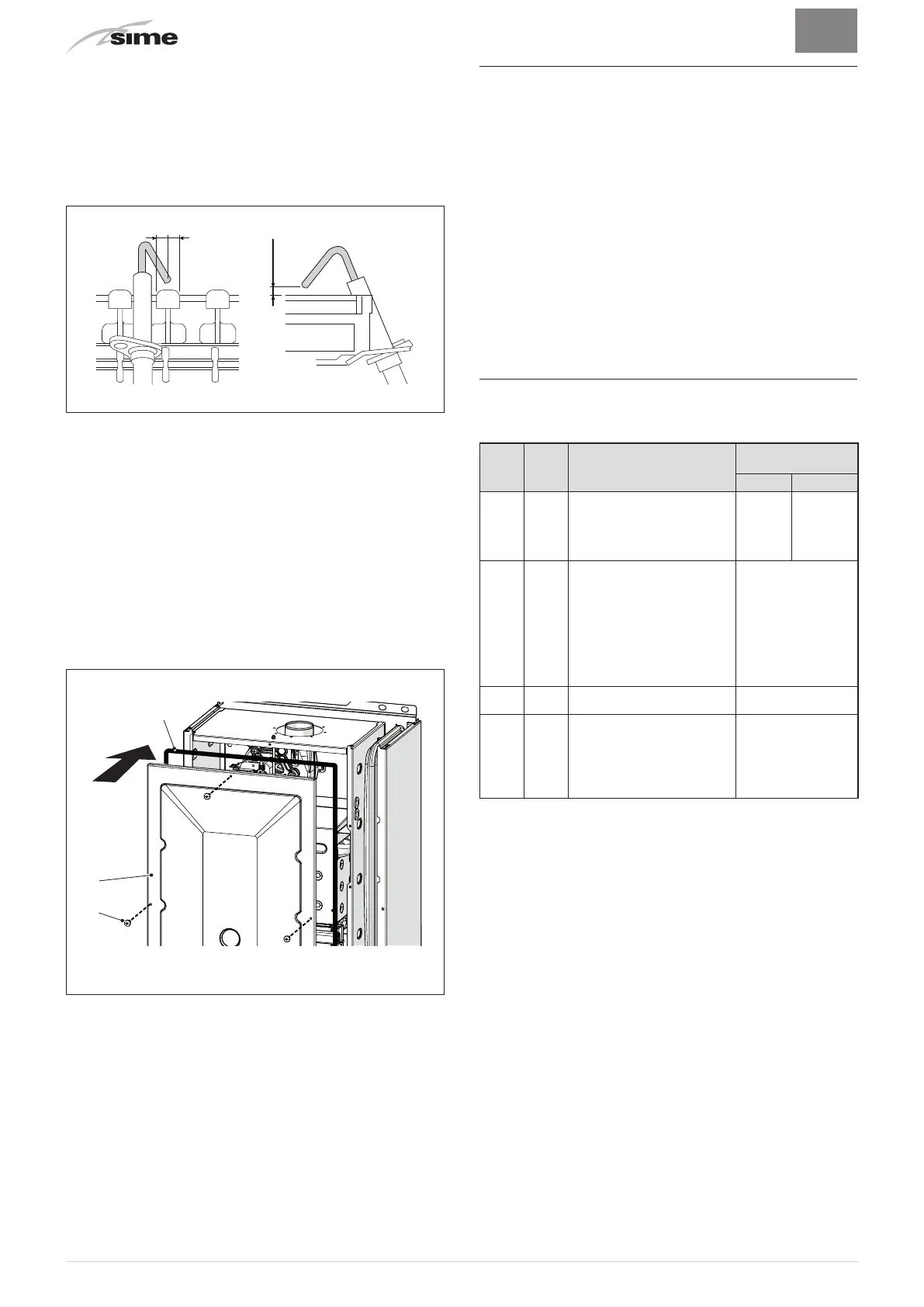

8.3.3 Checking the ignition/detection electrode

Check the state of the ignition/detection electrode and replace

if necessary. Check the measurements as per the drawing

whether the ignition/detection electrode is replaced or not.

3,5

+0,5

-0,5

Fig. 59

m

CAUTION

The position of the electrode is essential for the correct

detection of current ionization.

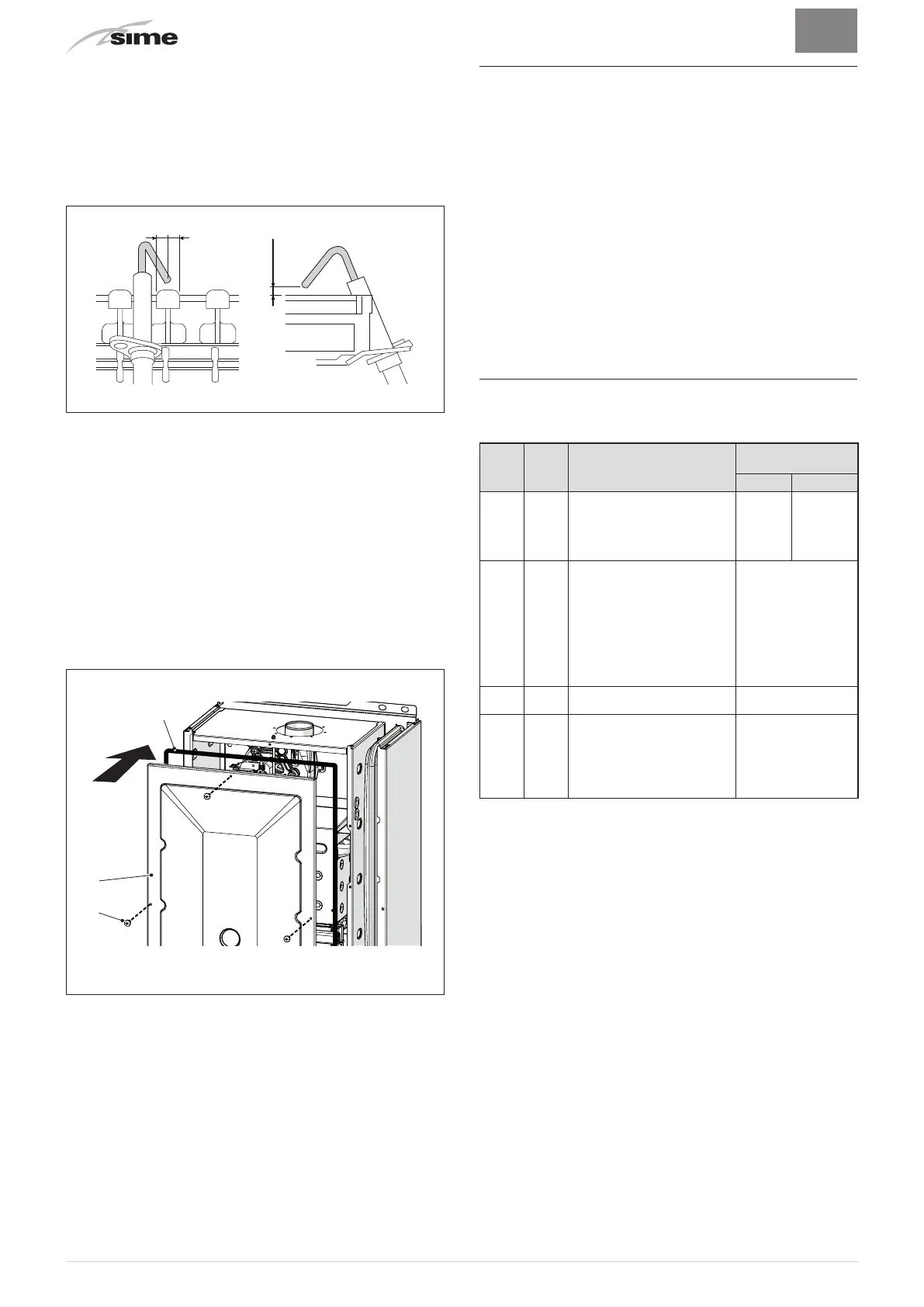

8.3.4 Final operations

After having cleaned the heat exchanger and the burner:

– remove any carbon residue using a vacuum cleaner

– check that the gasket and the insulation of the front panel (6)

of the combustion chamber and the gasket (13) of the front

panel (4) of the sealed chamber are all integral. If they are

not, replace them

– refit the panels (6) and (4) securing them with fastening

screws.

Fig. 60

8.4 Checks

8.4.1 Checking the smoke duct

It is recommended that the user checks that the combustion air

inlet duct and smoke outlet duct are integral and airtight.

8.4.2 Checking the expansion vessel pressure

It is recommended that the expansion vessel on the water side

is drained and that the prefilling pressure is not less than

1 bar

.

If this is not the case, pressurize it to the correct value (see

sectionExpansion vessel".

Once the checks described above have been completed:

– refill the boiler as described in section "REFILL operations"

– start the boiler up and carry out a smoke analysis and/or

measure the combustion efficiency.

– refit the front panel securing it with the two screws which

were removed previously

8.5 Unscheduled maintenance

If replacing the

electronic board

, the user MUST set the

parameters as indicated in the table.

Type No. Description

Setting for

Brava

One BF

25 30

tS 0.1

Index showing boiler power

in kW

0 = 25; 1 = 30 or the type of

exchanger = 4 (aluminium for

25 kW)

0 or 4 1

tS 0.2

Hydraulic configuration

0 = rapid

1 = storage tank with

thermostat or heating only

2 = hot water tank with

sensor

3 = bithermic

4=instant with solar power

input

0

tS 0.3

Gas Type Configuration

0 = G20; 1 = G31

0 or 1

tS 0.4

Combustion configuration

0 = sealed chamber with

combustion control

1 = open chamber with smoke

thermostat

2 = low NOx

0

To enter "Parameter setting and display"refer to the indications

provided in the specific section.

Once the parameters in the table have been set, you must carry

out the "Automatic calibration procedure".

If the

gas valve

and/or the

ignition/detection electrode

and/or the

fan

are replaced, the user must still carry out the entire phase

of "Automatic calibration procedure" described in the specific

section.

Loading...

Loading...