MAINTENANCE

0607SE Maintenance Manual 5-13 © Jan 2022

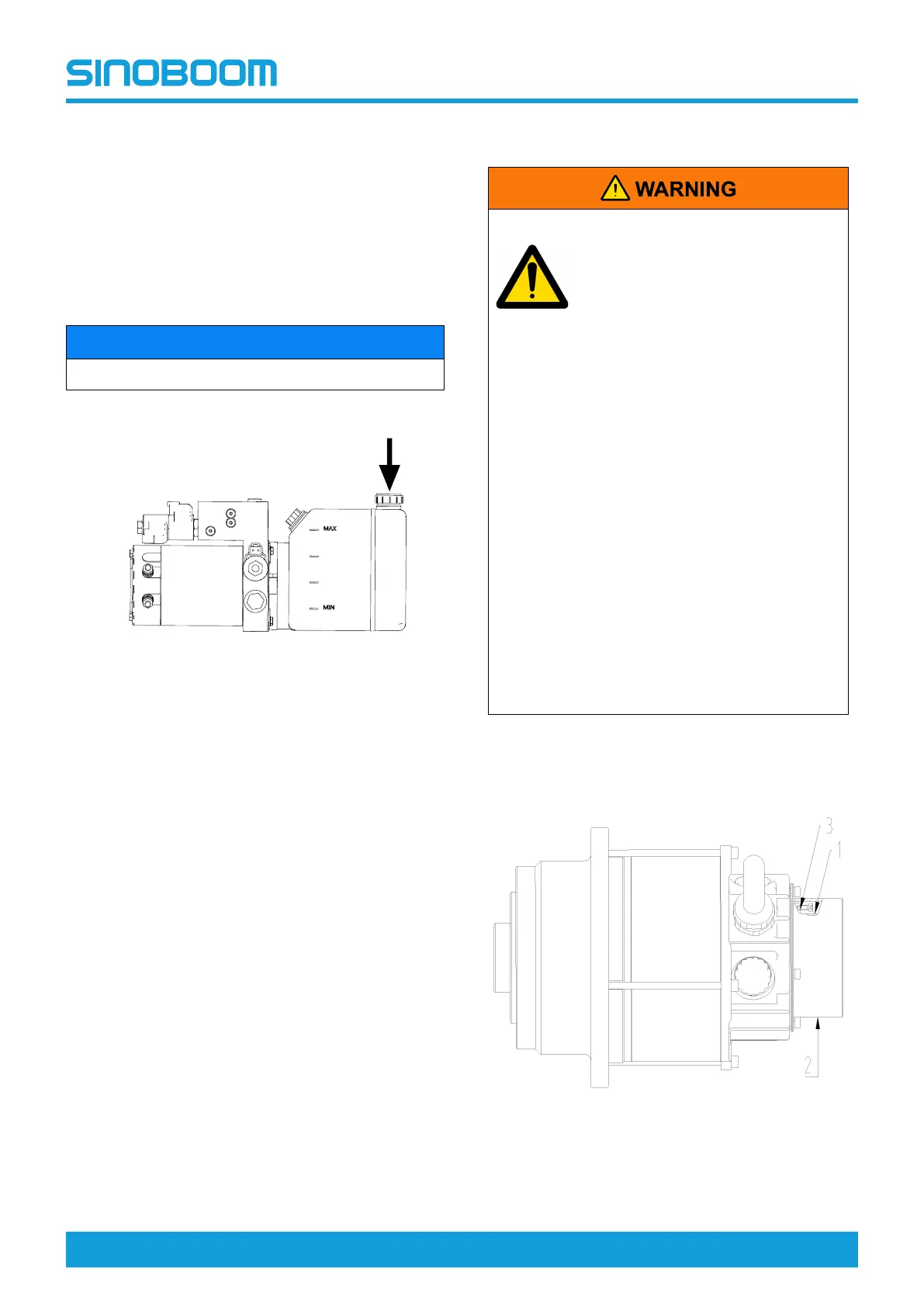

B-5 Inspect Air filter of Hydraulic Tank

Keeping the breather cap of hydraulic tank in well-

ventilated condition is vital to normal operation of

hydraulic pump and extending service life. Dirty or

blocked air filter of hydraulic tank may cause the

hydraulic pump to suction improperly, and continued

operation may result in component damage. The air

filter of hydraulic tank should be inspected more often

in hostile operating environment.

NOTICE

Shut off the machine before inspection.

1. Remove the air filter of hdraulic tank.

Figure 5-7

2. Check the air filter of hydraulic tank.

3. The air should pass through the air filter smoothly.

4. If the air has difficulty in passing through the air

filter, observe the following steps to clean the air

filter or replace with a new one.

5. Use neutral solvent to clean the air filter, then dry it

up using an air gun, and check the air filter again to

ensure air can go through smoothly.

6. Install the clean or new air filter to the hydraulic

tank.

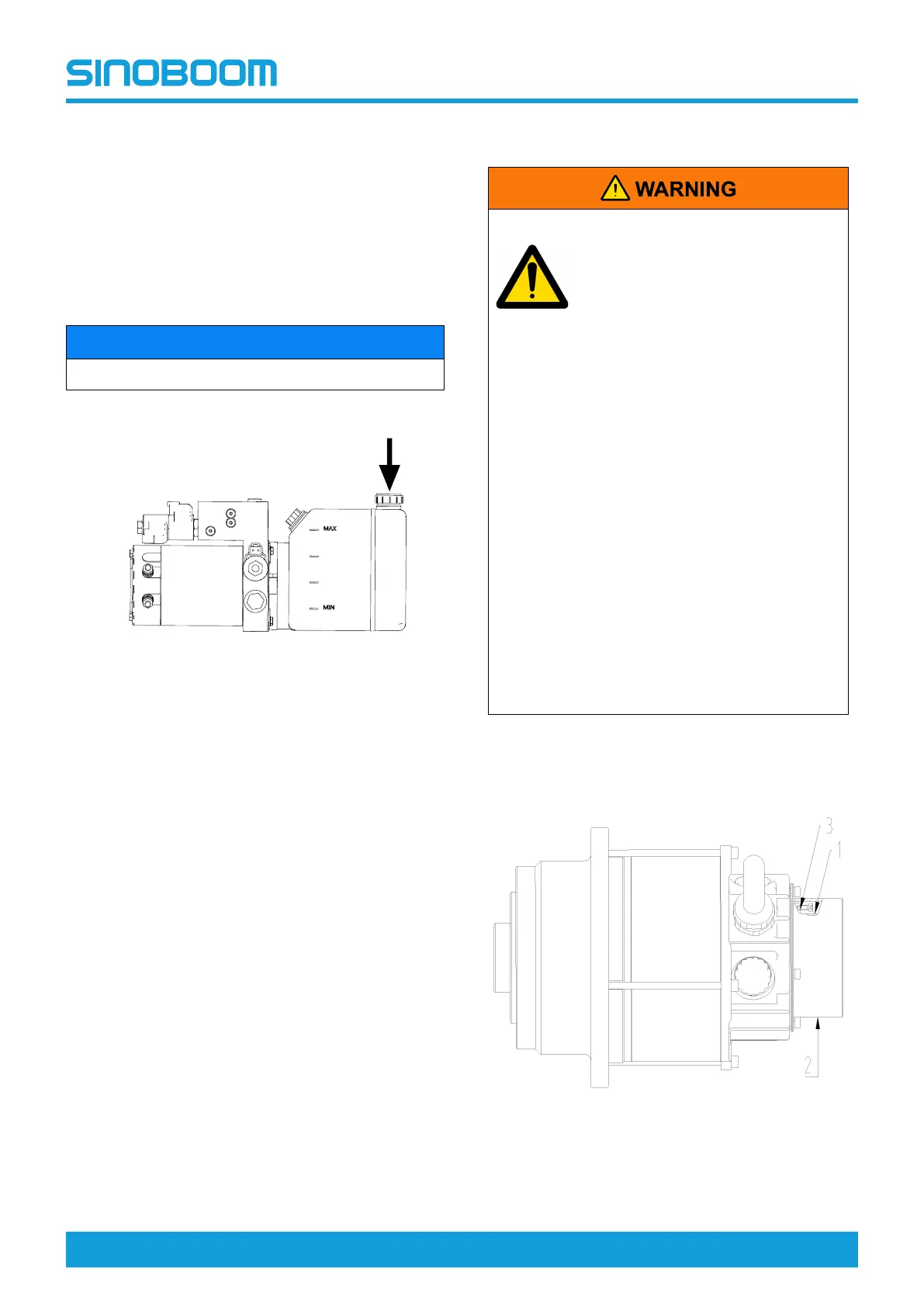

B-6 Inspect Manual Brake Release

UNSAFE OPERATION HAZARD

• Unless in case of emergency

situations, machine

malfunction, power loss or

loading/unloading, it is strictly

prohibited to tow or drag the

machine.

• When towing/dragging the

machine, there should be no

person in the platform.

• Before towing/dragging the

machine, ensure that the

machine is in stowed position

with the turntable securely

locked and platform free of any

tools or objects.

• Do not tow/drag the machine

with the engine started or the

drive hub engaged.

• The machine must be on a level

surface or secured before

releasing the brake.

• The towing/dragging of the

machine must follow the local

laws and traffic rules.

The machine needs towing/dragging in case of an

emergency, machine malfunction or power loss. There

are two methods to release the brake:

Method 1:

Figure 5-8

Loading...

Loading...