REPAIR

0607SE Maintenance Manual 6-5 © Jan 2022

wheel bolts and install in sequence. Rear wheels:

align the mounting holes of the new wheel or the

one to be used with the center axis of bearing

housing, and then tighten the nut.

NOTICE

Wheel nuts should be torqued prior to first use of

machine and after each wheel removal. Check

torque every 3 months or 150 hours of operation.

Removing the Reducer & Drive Motor

The reducer & drive motor not only serves a power

drive but also helps in securing the front wheels,

therefore, before removing the reducer & drive motor,

support the machine on a suitable structure or place a

jack of ample capcity under the chassis.

NOTICE

Be sure to disconnect the battery charger and main

power from the machine before removing the reducer

& drive motor.

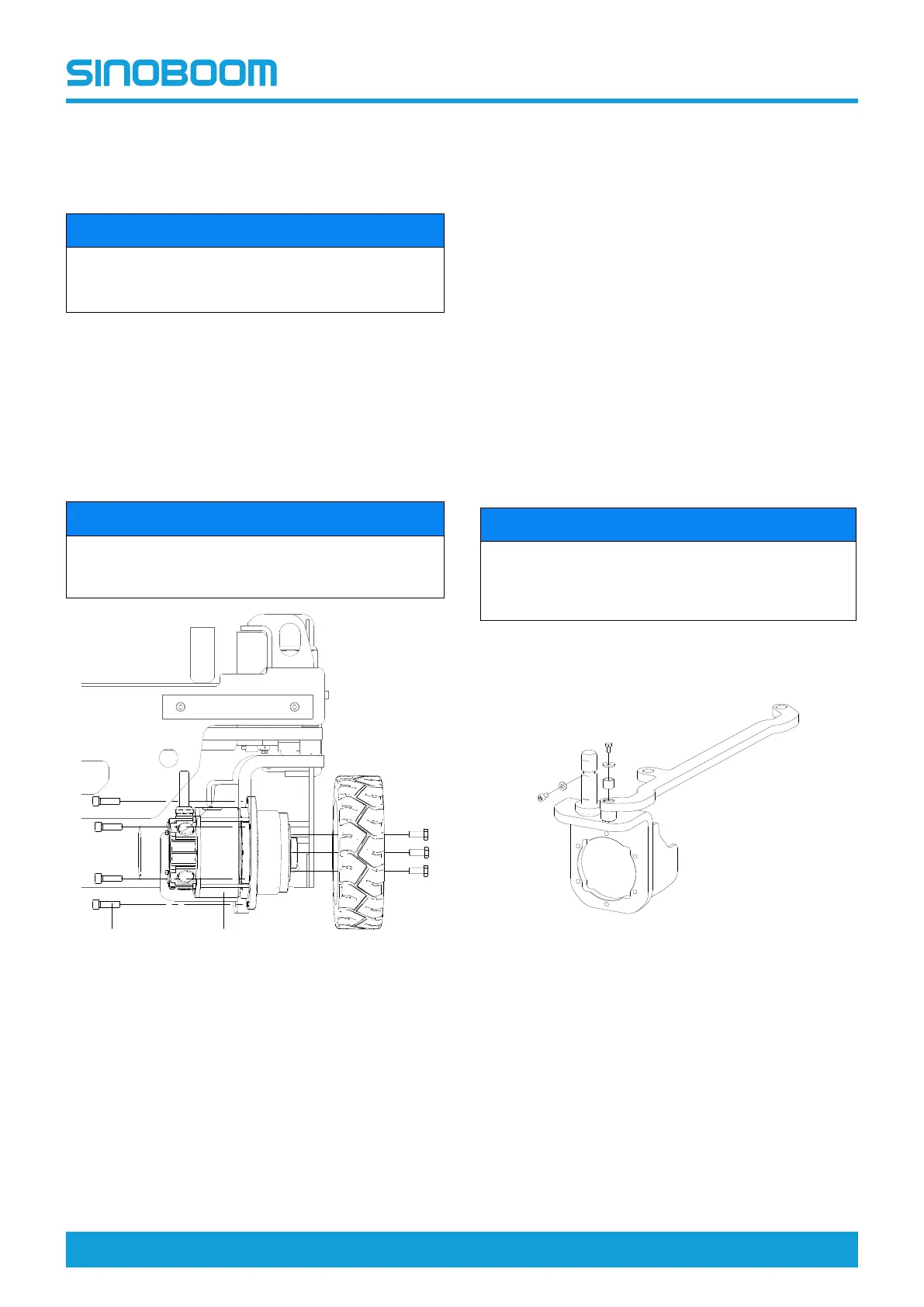

Figure 6-7

Removal of reducer and drive motor

1. Place the machine on a solid, level surface.

2. Place a jack of sufficient capacity under the side of

chassis to be removed. Lift the jack to make the

wheel off the ground.

3. Remove the wheel assembly, refer to Tires and

Rims, page 6-3.

4. Tag and disconnect the electric wiring to the

reducer & drive motor.

5. Use a suitable lifting device to support the reducer

& drive reducer.

6. Remove the bolt #1 securing the reducer & drive

motor to the wheel support, and remove the reducer

& drive motor #2.

Installation of reducer and drive motor

1. Align the mounting holes of reducer & drive motor

with those of the wheel support.

2. Apply threadlocker Loctite 272 to the bolts,and intall

in turns.

3. Tighten the bolts with a torque wrench.

4. Connect the electric wiring.

5. Install the wheel assembly. Refer to Tires and

Rims, page 6-3.

Removing the Front Wheel Bracket

NOTICE

When installing the removed hose and fitting, it must

be tightened according to the specified torque. See

Hydraulic Hose and Fitting Specifications, page

2-5.

Be sure to use a lifting device with adequate capacity to

lift the chassis. Be sure to place the lifting device at a

proper location on the chassis.

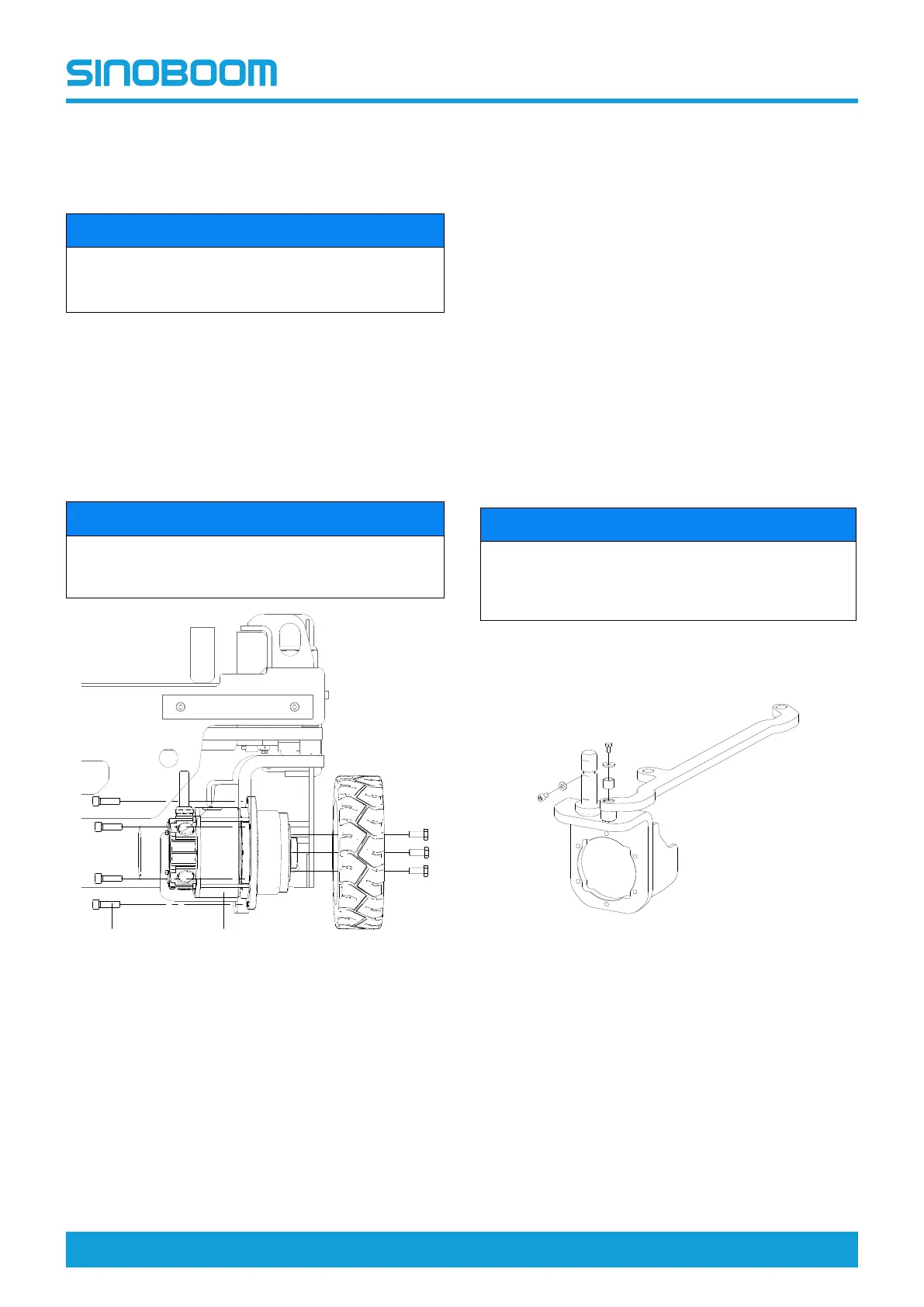

Figure 6-8

1. Disconnect the electrical components and wiring on

the drive motor.

2. Remove the bolt, washer and bearing #2 connected

to the steer linkage of the front wheel.

3. Remove the retaining bolt and washer #1 of the

front wheel bracket.

4. Remove the front wheel bracket.

Loading...

Loading...