31

5.7.3 Normal mode displays, single and dual line lubrication systems

Normal mode displays, which show lubrication program setpoints, can be browsed with ù.

Display codes change in the following order when

ù is pressed.

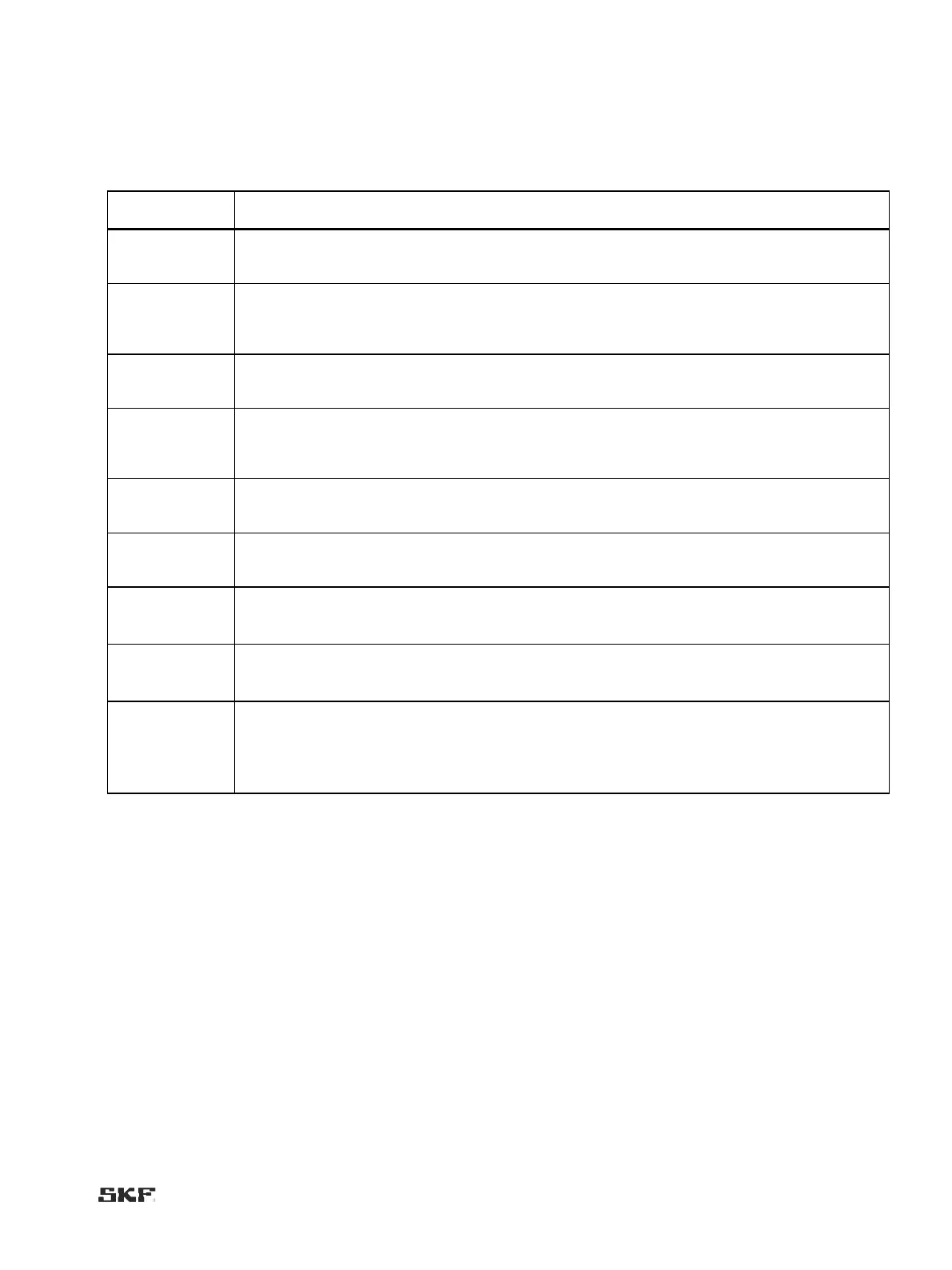

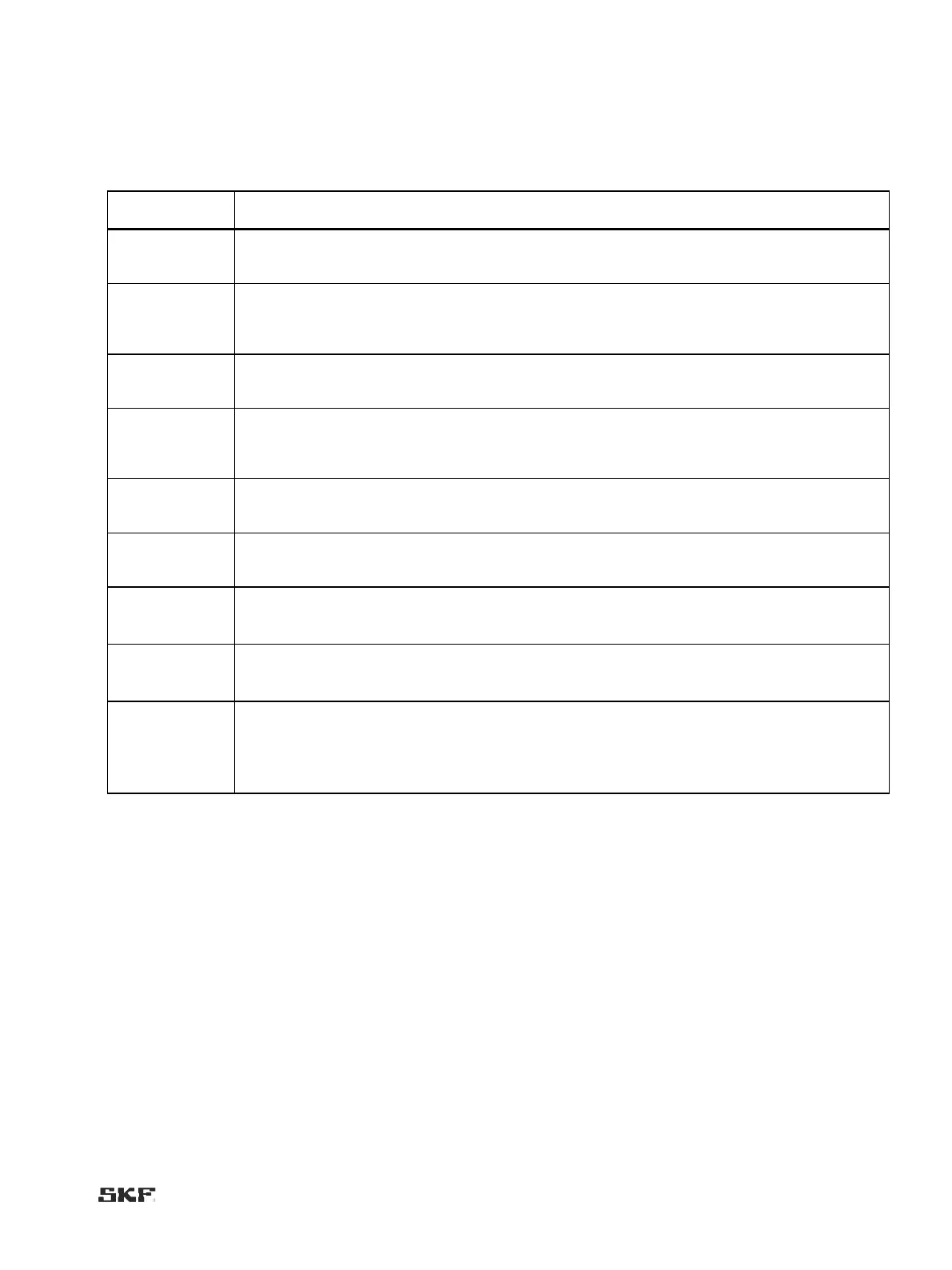

Display code Description

The lubrication channel selected on the display. The code is used only in dual-channel systems.

Press SET to switch to another channel when the code is displayed.

Lubrication cycle counter.

(Cycle Counter)

The counter reading increases by one unit when lubrication ends. A decimal point is used to

The lubrication cycle setting value as time [h.mm] or pulses, depending on the factory setting

parameter CYC. Can be set in the range of 0 min – 999 h or 000…999 pulses.

The maximum pressurisation time setpoint [s]. Can be set in the range of 0...999 s.

The setpoint can be changed to minutes with factory setting parameter Prt.

Can be set in the range of 0...999 min.

(Lubrication, Pressurization time)

The low limit pressure setpoint [bar/psi]. Can be set in the range of 0...200 bar/0...2,900 psi.

(Pressure, Low limit)

The code is used in pressure switch operation only.

The high limit pressure setpoint [bar/psi]. Can be set in the range of 0...200 bar/0...2,900 psi.

(Pressure, High limit)

The code is used in pressure switch operation only.

Pressure discharge delay multiplier [n]

(DELay) Delay = P * n [s]

The code is used in pressure switch operation only.

On: Manual operation mode

OFF: Automatic operation mode

The pump is currently in use when the dual pumping centre (Dualset) is in use:

1: Pump 1 in use.

2: Pump 2 in use.

This parameter is only displayed when YES has been set as the value of the dUA factory setting

Decimal points are used to separate thousands in the lubrication cycle counter reading. The counter’s max. reading is

49.9 = 49999.

Depending on the lubrication system’s factory setting parameter Pre, the pressure unit on the display is bar or psi. In the

psi reading, decimal points are used to separate thousands. For example, 1.02 = 1020 psi.

Loading...

Loading...