43

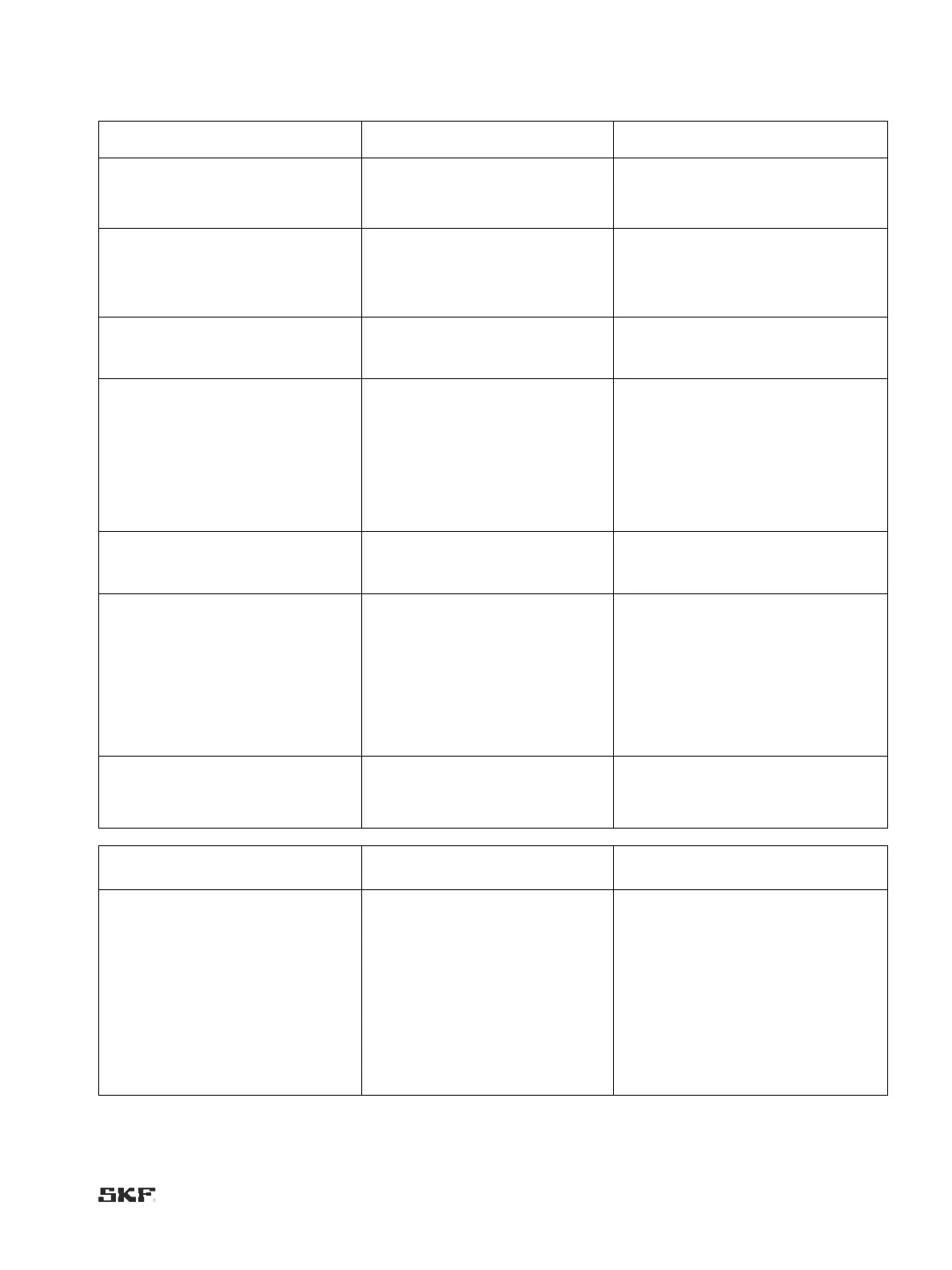

7. Maxilube troubleshooting table

Description of malfunction Cause of malfunction Solution

If internal control unit of SKF Maxilube

is in use:

The user interface display and the

No supply voltage to the pumping

Check the supply voltage.

If an external control centre is in use:

The green POWER LED of the control

centre is not lit and the user interface

is dark.

The control centre’s main switch

is in the OFF position.

Turn the main switch to the ON position.

The user interface displays a lubricant

barrel low level alarm in a lubrication

channel.

The lubricant barrel is empty.

Replace the lubricant barrel.

Reset the alarm.

The user interface displays a low

pressure alarm for the lubrication

channel. The pressure at the pressure

control unit is below the set pressure

high limit value during pressurisation.

The lubricant has stiffened in the

piping because of the operating

conditions (e.g. cold, heat).

Header piping is leaking.

There is air in the header piping.

Set the maximum pressurisation time

longer or replace the lubricant with an

appropriate type.

Locate and repair the damage.

Remove air from the header and branch

piping.

Considerable grease leakage at the

lubrication point.

The temperature of the bearing rises.

The lubrication cycle has been set

too short.

Check the correct lubrication cycle from

the doser setting table of the lubrication

system or contact Oy SKF Ab.

Compressed air supply has been cut

off.

Insufficient air pressure.

Turn on the compressed air supply by

pressing down the shut-off valve button.

(Fig. 8/e ).

Check that the pressure at the pressure

air regulator is 3.5–4.5 bar.

Check the air supply hoses for leaks.

The pump starts but pressure does

not increase.

Insufficient air pressure.

Check that the pressure at the pressure

air regulator is 3.5–4.5 bar.

Check the air supply hoses for leaks.

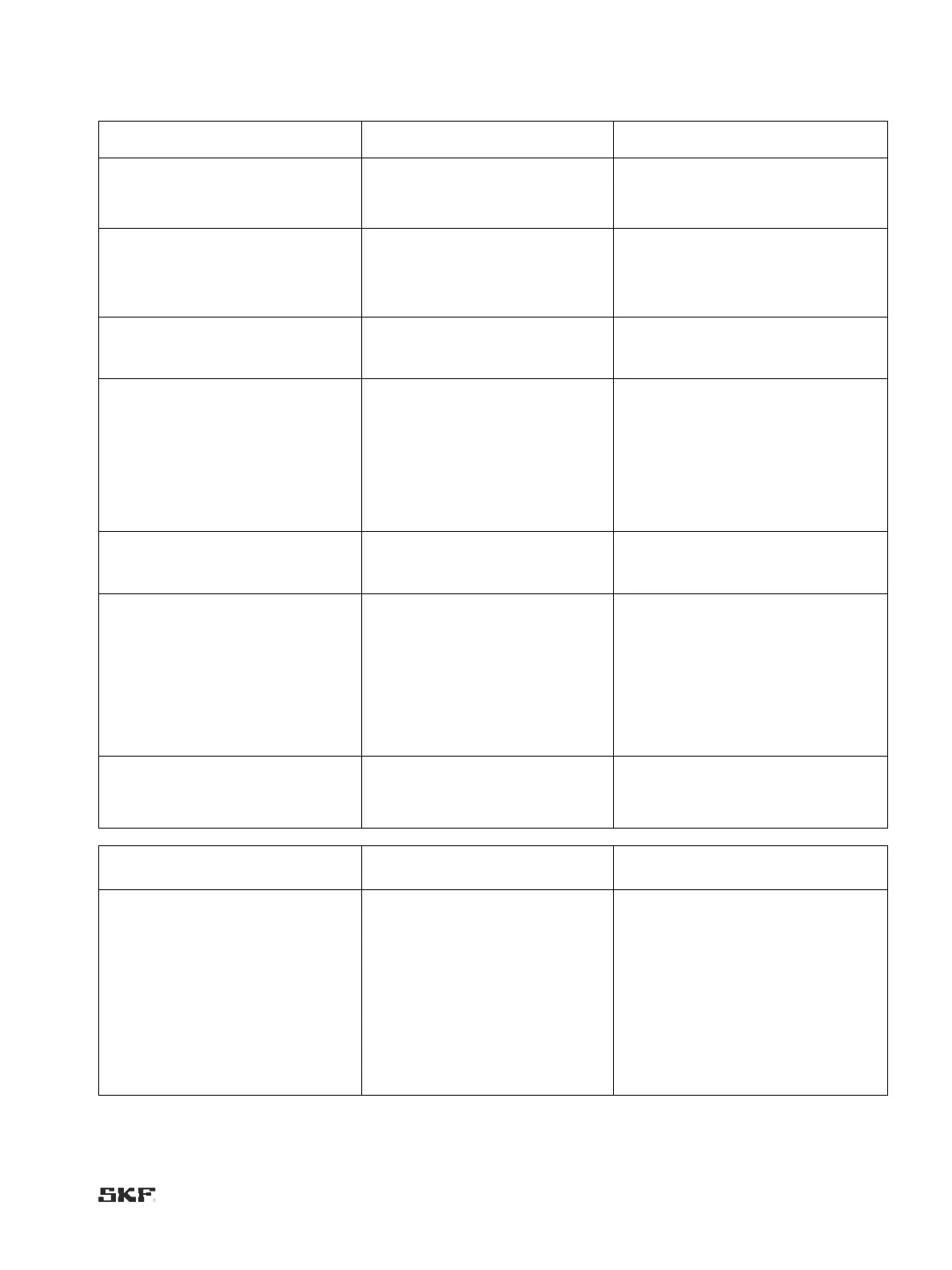

Description of malfunction Cause of malfunction Solution

The user interface displays an alarm

for high pressure in a lubrication

channel. The pressure at the pressure

control unit is above the set pressure

low limit value when pressurisation

starts.

The lubricant has stiffened in the

piping because of the operating

conditions (e.g. cold, heat).

The control valve of the changeover

valve unit is not working.

Set the lubrication cycle longer or

replace the lubricant with one

appropriate for the operating conditions.

Reset the alarm.

Check that the setpoints for high and

low limit pressure are correct. If

necessary, contact Oy SKF Ab.

Check the pressure of the compressed

air.

Check the operation of the solenoid

Loading...

Loading...