BlueControl Insect

Technical User Guide 7

2 Product description

BlueControl insect is a controller developed for insect farming systems with a focus on the soldier fly and meal-

worms. It is thus intended for breeding and growth of larvae and pupae, but can be adapted to most types of in-

sect farming systems.

Insect farming is an intensive form of production. The insects generate a lot of heat, just like the level of CO

2

and NH

3

can be high in the room. It requires efficient ventilation with high air change, which ensures good pro-

duction conditions throughout the house.

BlueControl insect meets the insects' special needs for climate control with recirculation, humidification, ventila-

tion boost and curve control on an hourly basis. The ventilation can be controlled as an equal pressure system

and as a central exhaust system.

The controller is available in two variants, both of which are used in a total insect ventilation system:

• BlueControl insect system (section ventilation)

• BlueControl insect central in/out (central exhaust and central air intake)

The controller is operated via a touch display with graphical views of the ventilation status, icons and curves,

among other things.

BlueControl insect central in/out is used for controlling the pressure in an exhaust duct for central exhaust venti-

lation system.

It can also be used in houses where fresh air needs to be heated up or cooled down before it enters the house.

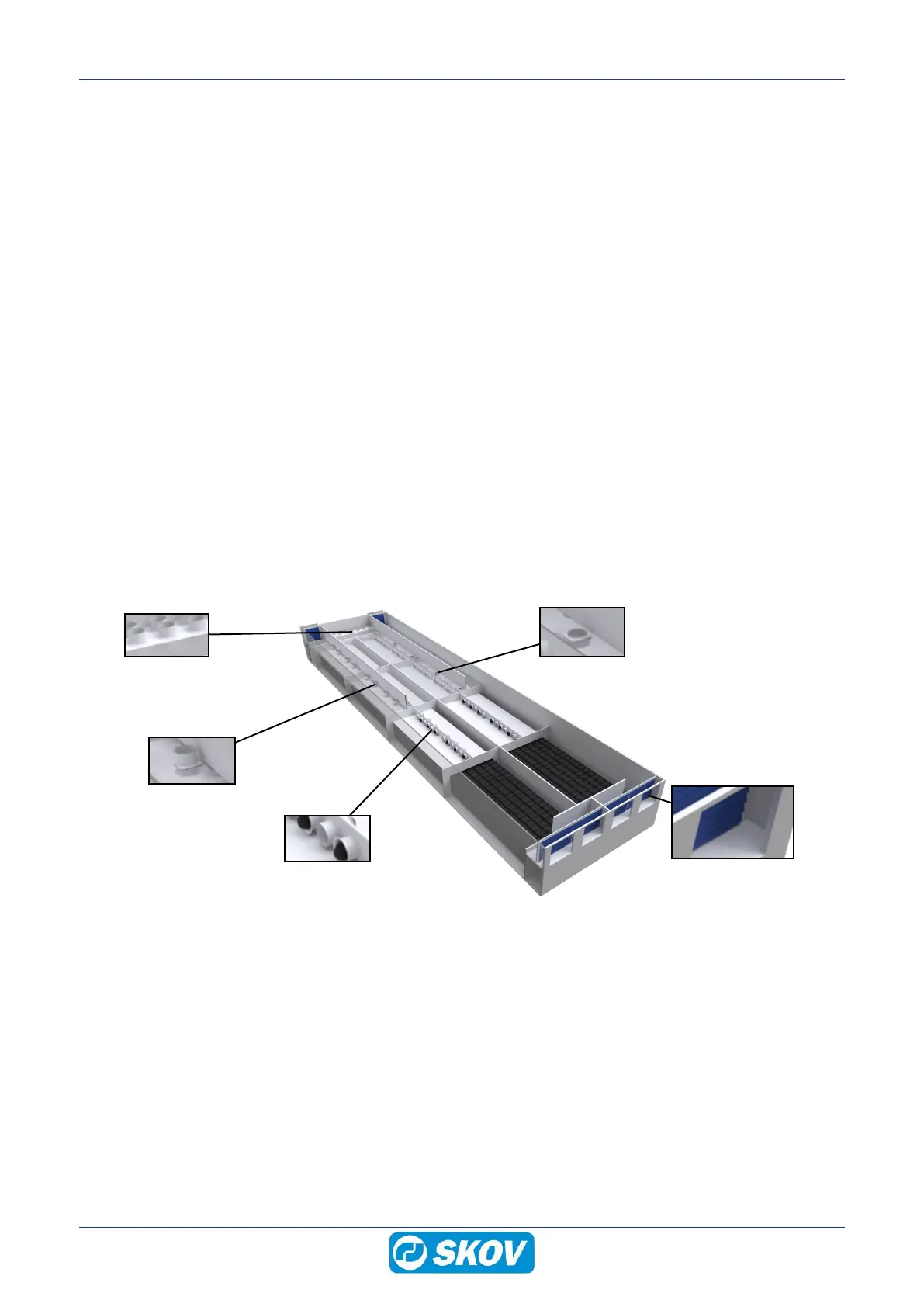

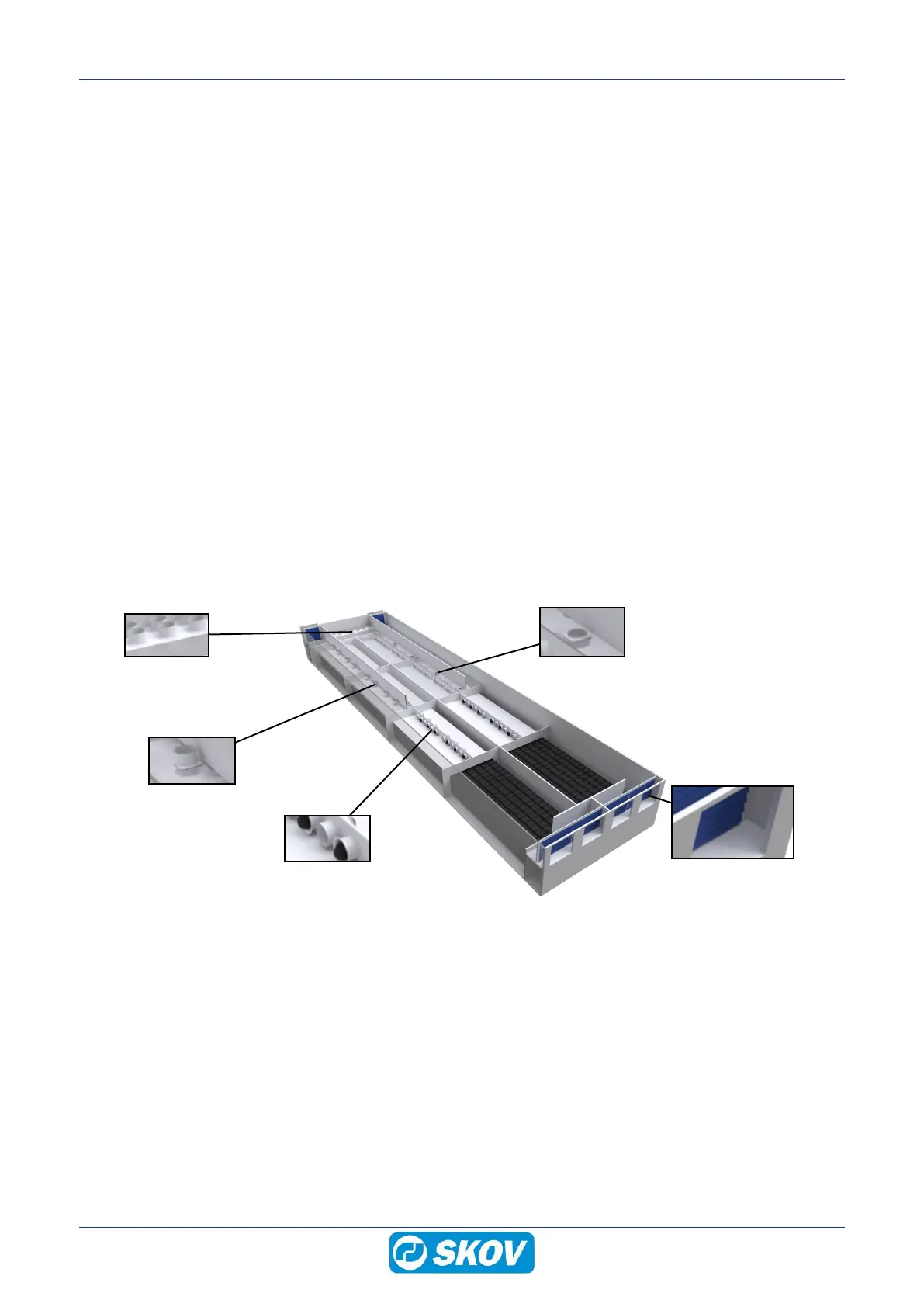

Nursery, grow-out and pupa house

Central exhaust - fan bank

BlueControl insect central in/out

Air outlet

BlueControl insect system

Air inlet

BlueControl insect system

Recirculation unit

BlueControl insect system

Air inlet

BlueControl insect central in/out

Figure1: Ventilation components in an insect house with grow-out crates

In production systems for soldier flies, humidity control and removal of humidity with the ventilation air is crucial

in pupa, nursery and growth sections. The flies are produced here in a moist substrate, and the heat production

of the larvae is released especially in the form of water vapor.

During the growth-out period, the moisture content of the substrate changes. Typically, the substrate has a dry

matter content of approx. 30 % at the start, while at the end it must have a dry matter content of 50-60 %. Dur-

ing the production it is important to maintain such a high moisture content in the substrate that the larvae can

eat the dry matter. The larvae have no teeth and therefore they have to suck in the food. Likewise, it must be

avoided that the surface dries out, as this can make the substrate inaccessible to the larvae, and cause it to

form cakes/crusts, which will be sieved off together with the larvae at the end of production. At the end, it must

be so dry that the larvae can be sieved from the frass. See the section about Humidity.

Loading...

Loading...